Cathode catalyst for hollow nano water electrolysis, and preparation method thereof

A cathode catalyst and electrolyzed water technology, applied in the field of electrocatalysis, can solve the problems of high potential, achieve high electrocatalytic activity, improve catalytic performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

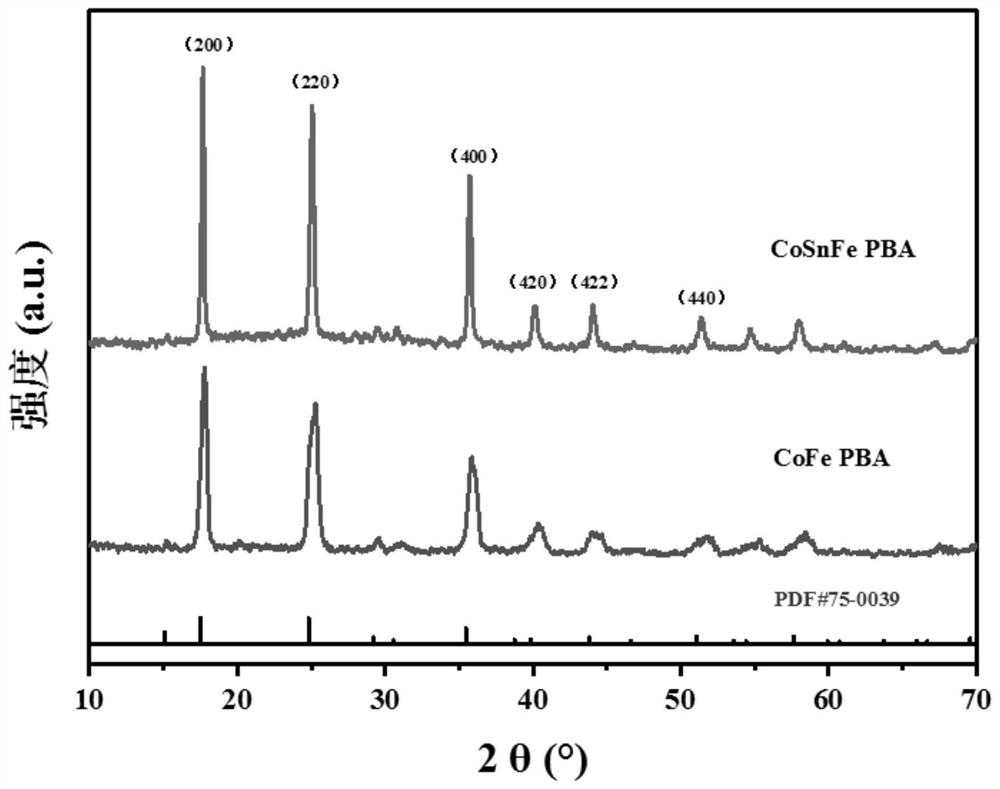

[0029] A method for preparing a cathode catalyst for hollow nanometer electrolyzed water of the present invention comprises two schemes, specifically as follows:

[0030] The first option:

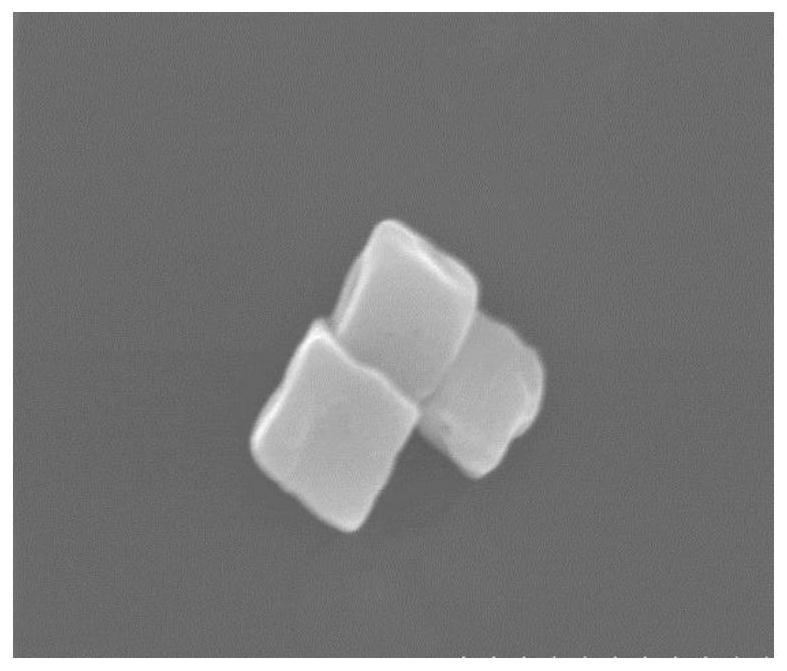

[0031] Weigh the cobalt salt of 0.1-1mmol and the sodium citrate dihydrate of 0.5-2mmol, wherein the cobalt metal salt can be one or more of cobalt chloride hexahydrate, nitrate, sulfate and acetate, because the ratio There is no requirement, and the effect is the same, so the following examples only list each pure substance, dissolve them in 10-30mL deionized water, add potassium ferricyanide aqueous solution while stirring, and the potassium ferricyanide aqueous solution passes through 0.2-0.5 Dissolve one mmol of potassium ferricyanide in 10-30mL of deionized water and mix evenly, continue to stir for 5-30min to obtain a mixed solution, let it stand for 20-48h, centrifuge the product, wash with deionized water and absolute ethanol, After vacuum drying, CoFe-PBA cubes were synthesized b...

Embodiment 1

[0039]142.758 mg, namely 0.6 mmol of cobalt chloride hexahydrate and 264.69 mg, namely 0.9 mmol of sodium citrate dihydrate were dissolved in 20 mL of deionized water to form solution A, and 0.4 mmol of potassium ferricyanide was dissolved in 20 mL of deionized water to form solution B. Slowly pour solution A into the stirring solution B to obtain a mixed solution, let it stand for 48 hours, centrifuge, wash and vacuum dry the product for 24 hours to obtain CoFe-PBA.

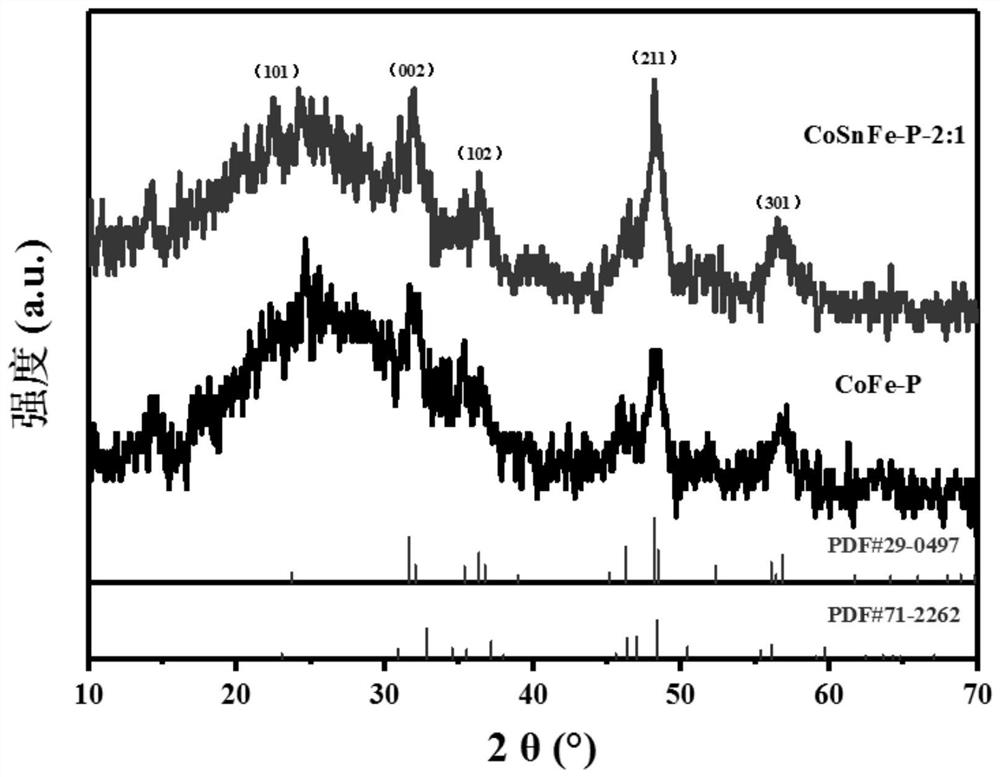

[0040] Weigh 200mg of CoFe-PBA cube, put it in a small crucible, then weigh 1g of NaH 2 PO 2 Put it into a large crucible, put the small crucible in the large crucible, and react at 350°C for 2h to obtain a hollow PBA cube.

[0041] 95.172mg or 0.4mmol of cobalt chloride hexahydrate, 45.126mg or 0.2mmol of stannous chloride and 264.69mg or 0.9mmol of sodium citrate dihydrate were dissolved in 20mL of deionized water to form solution A, 0.4mmol of potassium ferricyanide Dissolve in 20mL deionized water to form ...

Embodiment 2

[0049] Dissolve 0.1mmol of cobalt chloride hexahydrate and 0.5mmol of sodium citrate dihydrate in 20mL of deionized water to form solution A, dissolve 0.3mmol of potassium ferricyanide in 20mL of deionized water to form solution B, and slowly pour solution A into In the stirring B solution, a mixed solution was obtained, which was left to stand for 20 hours, and the product was centrifuged, washed, and vacuum-dried for 24 hours to obtain CoFe-PBA.

[0050] Weigh 250mg of CoFe-PBA cube, put it in a small crucible, then weigh 2g of NaH 2 PO 2 Put it into a large crucible, put the small crucible in the large crucible, and react at 200°C for 1 hour to obtain a hollow PBA cube.

[0051] Dissolve 0.1mmol of cobalt chloride hexahydrate, 0.8mmol of stannous chloride and 0.5mmol of sodium citrate dihydrate in 20mL of deionized water to form solution A, and dissolve 0.3mmol of potassium ferricyanide in 20mL of deionized water to form solution B , slowly pour solution A into the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com