Rare-earth-ion-doped cerium trifluoride/graphite-phase carbon nitride composite photocatalytic material, and preparation method and application thereof

A graphite phase carbon nitride, composite photocatalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, special compound water treatment, etc., can solve the problem of low photocatalytic activity, easy recombination of photogenerated electron holes, sunlight problems such as low utilization rate, to achieve the effect of good photocatalytic activity, uniform distribution, and promotion of effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of a rare earth ion-doped cerium trifluoride-graphite phase carbon nitride composite photocatalytic material, comprising the following steps:

[0027] (1) After 5g of dicyandiamide is put into a mortar and ground into a fine powder, it is dried at 80°C for 10 hours, then fully ground, and then the crushed powder is put into a crucible and placed in a muffle furnace at 5°C / min heating rate, calcined at 550°C for 4 hours and cooled in the furnace, and obtained light yellow graphite phase carbon nitride powder g-C after grinding 3 N 4 ;

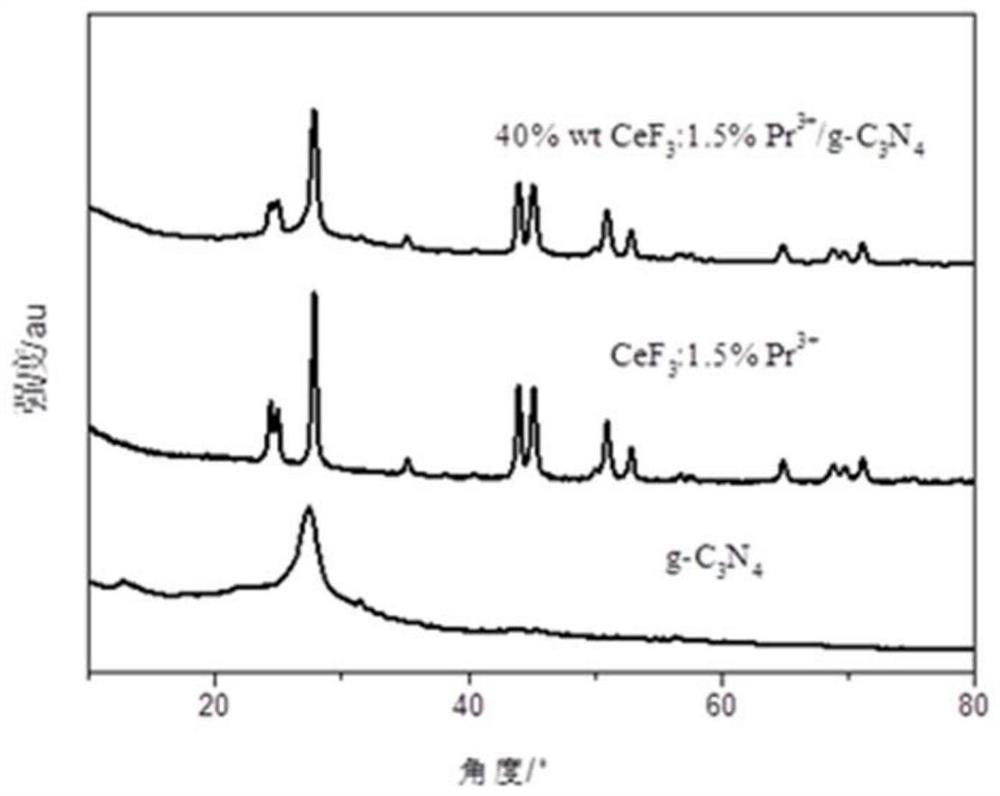

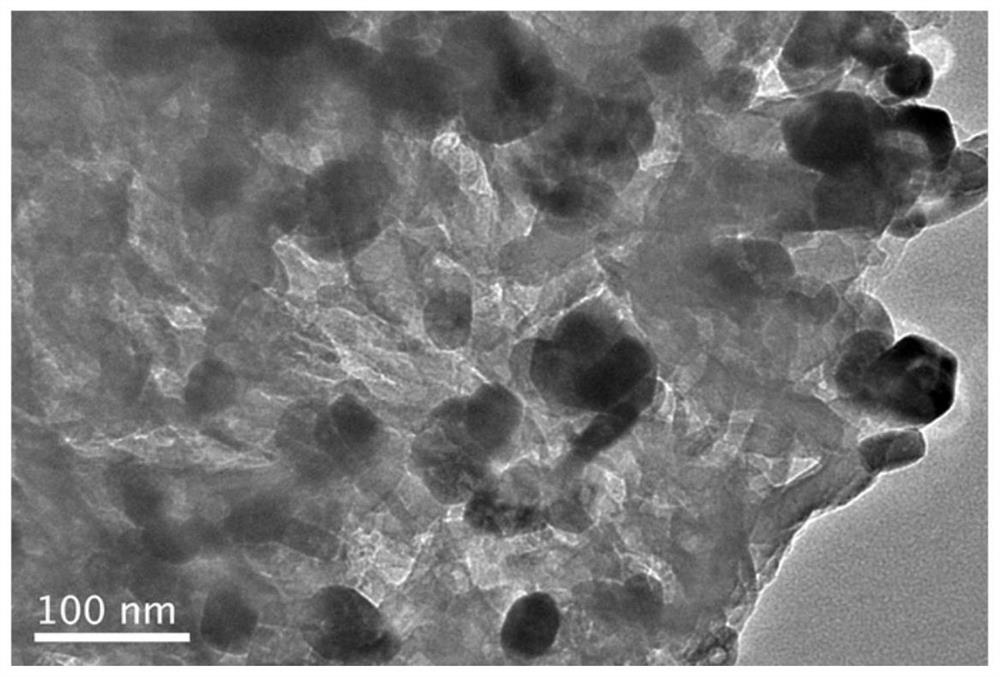

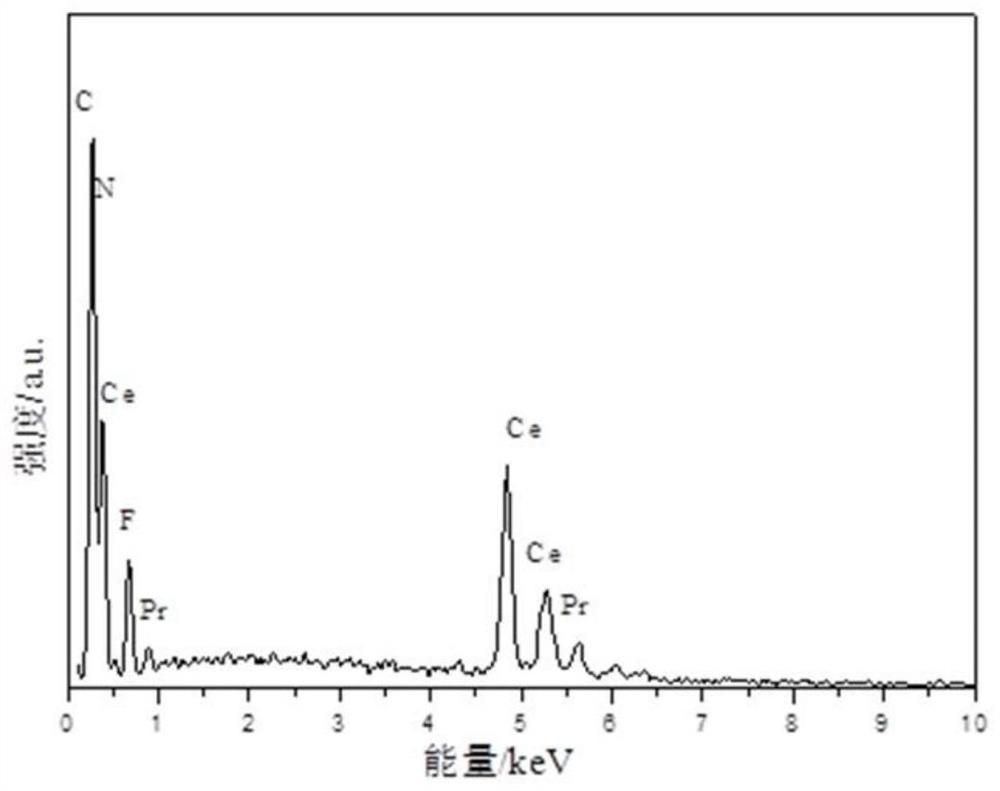

[0028] (2) Weigh 2g of g-C 3 N 4 Dissolved in deionized water and ultrasonicated for 30 minutes to obtain a suspension solution, 1.736gCe(NO 3 ) 3 ·6H 2 O, 0.0265g Pr(NO3 ) 3 ·6H 2 O, 0.45g NH 4 Add F to the suspension solution above, then slowly add acetic acid dropwise to adjust the pH of the system to 4-5, and finally add the mixed solution to the hydrothermal reaction kettle for 10 hours of hydrothermal ...

Embodiment 2

[0033] The 40%wt CeF prepared in Example 1 3 :1.5%Pr 3+ / g -C 3 N 4 The application of composite materials on the degradation of dye wastewater, the application includes the following steps:

[0034] Weigh 0.05g methylene blue and dissolve it in 500mL deionized water to prepare a 100mg / L methylene blue solution, add 0.01g, 40%wt CeF 3 :1.5%Pr 3+ / g -C 3 N 4 Composite material, after dark adsorption for 30 minutes, introduce visible light, take 3mL reaction solution every 30 minutes, transfer to a centrifuge tube, centrifuge the sample in the centrifuge tube at 6000r / min for 5 minutes, collect the supernatant after centrifugation, and transfer it further In the quartz cuvette, measure its absorbance (the methylene blue maximum absorption wavelength is at 665nm place) at the dyestuff maximum absorption wavelength place with a spectrophotometer, the methylene blue degradation rate is calculated according to the following formula:

[0035] D=(1-A / A 0 )×100%

[0036] Where...

Embodiment 3

[0038] Get the light yellow graphite phase carbon nitride powder g-C prepared by step 1 in embodiment 1 3 N 4 , for subsequent experiments.

[0039] (1) Weigh 2g of g-C 3 N 4 Added into deionized water and ultrasonicated for 30 minutes, 0.434gCe(NO 3 ) 3 ·6H 2 O, 0.0066g Pr(NO 3 ) 3 6H2O, 0.1125g NH 4 Add F to the suspension solution, slowly add acetic acid dropwise to adjust the pH of the system to 4-5, and finally add the mixed solution to a hydrothermal reaction kettle at 160°C for 10 hours of hydrothermal reaction.

[0040] (2) The sample obtained in step (1) was added to deionized water and ethanol for multiple centrifugal washing, dried at 80°C for 10 hours, and ground to obtain 10%wt CeF 3 :1.5%Pr 3+ / g -C 3 N 4 composite material.

[0041] Subsequent detection is as in Example 1, and the degradation rate of methylene blue reaches 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com