Formula and preparation method of waterborne polyurethane ink vehicle for food flexible packaging

A technology for ink binders and flexible packaging, applied in inks, applications, household appliances, etc., can solve the problems of slow curing of two-component inks, affecting production efficiency, loss of flexibility, etc., and achieves excellent high-temperature cooking resistance and good environment Protective, effects that meet the conditions of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

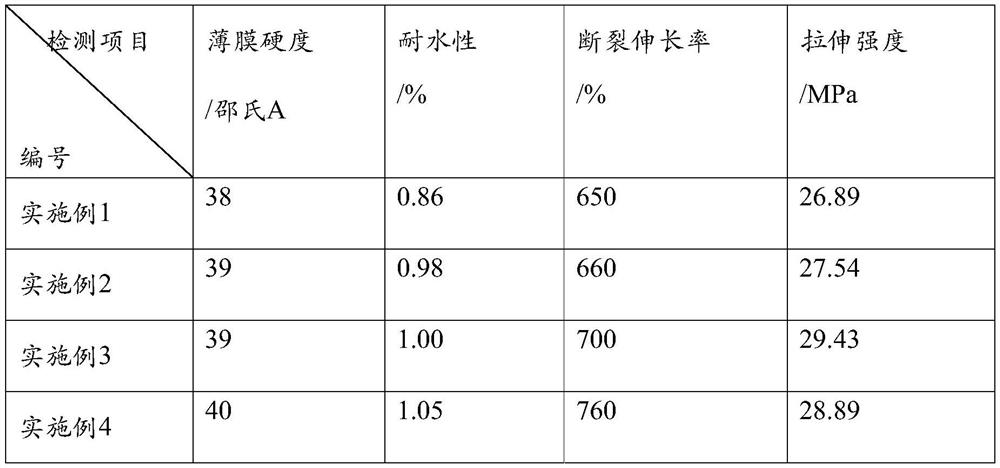

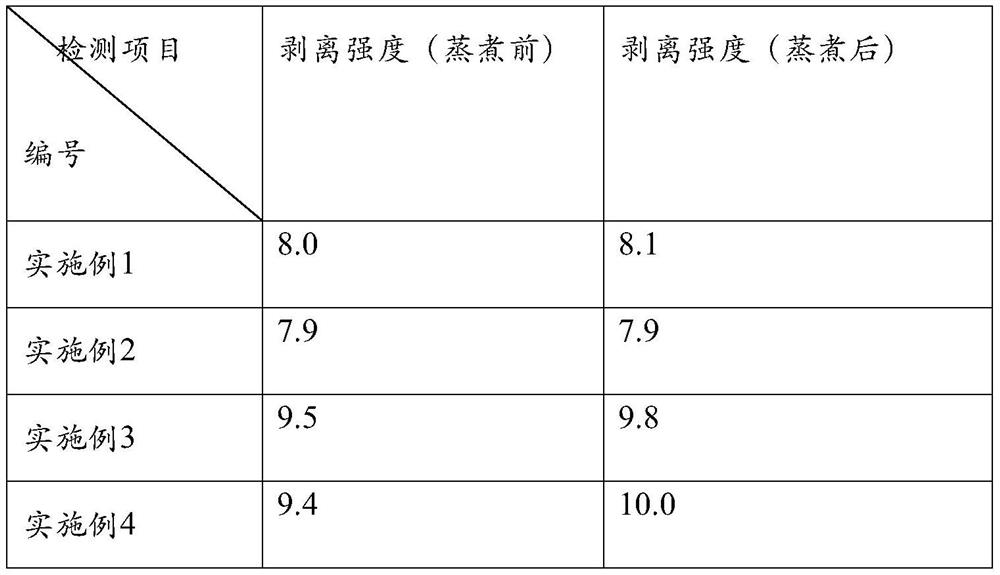

Examples

Embodiment 1

[0039] The formula of water-based polyurethane ink binder for food flexible packaging includes:

[0040] Polyether polyol SE-2038 (M=3000) of Shandong Dexin Chemical: 200.6kg, isophorone diisocyanate (IPDI): 27.9kg, hexamethylene diisocyanate (HDI): 14.1kg, bismuth sulfonic acid Base catalyst: 0.1174kg, dimethylolpropionic acid: 6.0kg, 1,6-hexanediol: 1.4kg, 1,2-propanediol carbonate: 30kg, dimethylaminoethanol: 4.0kg, German BASF antioxidant Irganox1010: 1.0kg, German BASF UV absorber TINUVIN 329: 1.0kg, Eastman cellulose acetate butyrate CAB-381-0.1: 2.0kg, deionized water: 357kg, non-ionic fatty alcohol polyoxyalkylene of Jiangsu Haian Chemical Industry Ether SF: 3.0 kg, ethylenediamine: 4.2 kg.

[0041] The preparation method of water-based polyurethane ink binder for food flexible packaging comprises the following steps:

[0042] (a) Synthesis of polyurethane prepolymer

[0043] Add polyether polyol SE-2038 (M=3000) and IPDI, HDI into the reactor, start stirring, contr...

Embodiment 2

[0049] The formula of water-based polyurethane ink binder for food flexible packaging includes:

[0050] Polyether polyol SE-2028 (M=4000) of Shandong Dexin Chemical: 203.6kg, IPDI: 25.5kg, HDI: 12.9kg, bismuth sulfonic acid catalyst: 0.1245kg, dimethylolpropionic acid: 6.5kg, 1,6-hexanediol: 1.5kg, 1.2-propylene glycol carbonate: 35kg, dimethylaminoethanol: 4.3kg, German BASF antioxidant Irganox 1010: 1.5kg, German BASF ultraviolet absorber TINUVIN 329: 1.5kg, Yi Shiman cellulose acetate butyrate CAB-381-0.1: 2.0kg, deionized water: 348kg, non-ionic fatty alcohol polyoxyalkyl ether SF of Jiangsu Haian Chemical Industry: 3.5kg, ethylenediamine: 4.0kg.

[0051] The preparation method of water-based polyurethane ink binder for food flexible packaging comprises the following steps:

[0052] (a) Synthesis of polyurethane prepolymer

[0053] Add polyether polyol SE-2028 (M=4000) and IPDI, HDI into the reactor, start stirring, control the temperature at 88°C for the first step of ...

Embodiment 3

[0059] The formula of water-based polyurethane ink binder for food flexible packaging includes:

[0060] Yantai Huada's polyester polyol CMA-66 (M=3000): 189.9kg, IPDI: 33.0kg, HDI: 16.6kg, bismuth sulfonic acid catalyst: 0.1436kg, dimethylolpropionic acid 7.0kg, 1, 4-cyclohexanedimethanol: 3.5kg, 1.2-propylene glycol carbonate: 35kg, dimethylaminopropanol: 4.6kg, German BASF antioxidant Irganox 1010: 2.0kg, German BASF ultraviolet absorber TINUVIN 329: 2.0kg, Eastman cellulose acetate butyrate CAB-381-0.1: 2.5kg, deionized water: 373kg, Jiangsu Haian Chemical Nonionic Fatty Alcohol Polyoxyalkylene Ether SF: 4.0kg, isophorone diamine: 15.0kg.

[0061] The preparation method of water-based polyurethane ink binder for food flexible packaging comprises the following steps:

[0062] (a) Synthesis of polyurethane prepolymer

[0063] Add polyester polyol CMA-66, IPDI, and HDI into the reactor, start stirring, control the temperature at 90°C for the first step of prepolymerization,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com