Niobium-doped bismuth oxybromide catalyst and preparation method and use method thereof

A technology of bismuth oxybromide and a catalyst is applied in the field of photocatalytic materials, which can solve the problems of easy recombination of photogenerated electron holes, low degradation ability of organic matter, low photon quantum efficiency, etc., and achieves the effects of controllable method, low price and good light absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

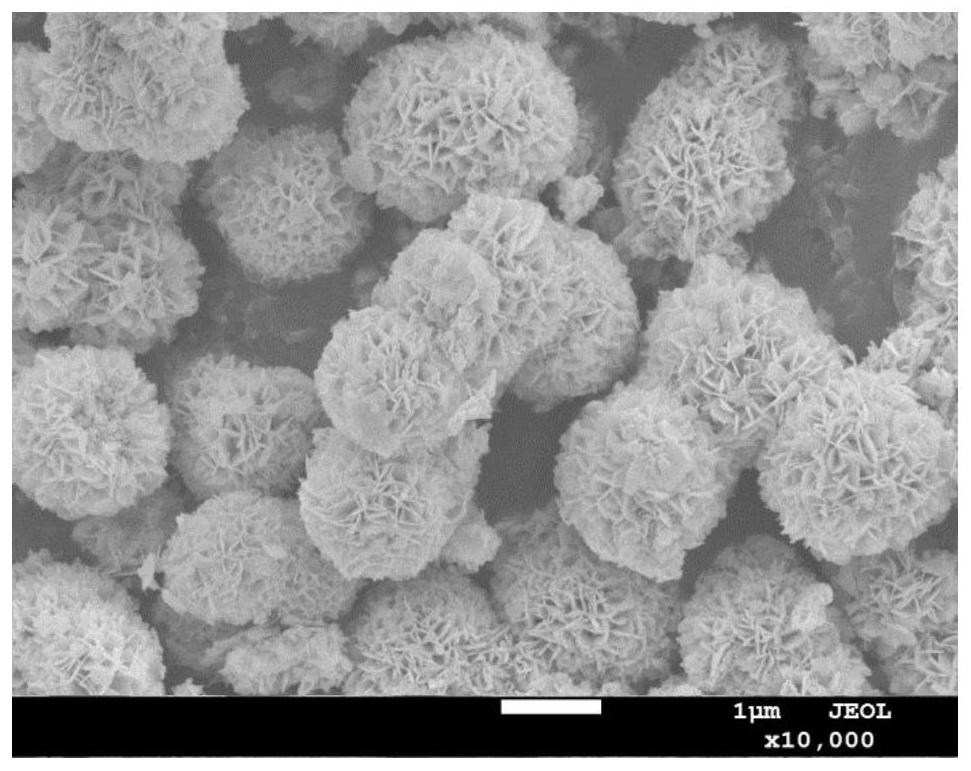

[0032] The present invention relates to a method for preparing a curd-shaped Nb-BiOBr photocatalyst. The method comprises the following steps: 1. Take an alcohol solvent and heat it to boiling and cool naturally; 2. Add a bismuth salt compound, a niobium compound and a bromine compound in sequence, mix and fully stir ; 3. Add neutral solution; 4. High-pressure constant temperature reaction; 5. Cool to room temperature, perform centrifugation, wash with water and ethanol solution respectively, collect powder after drying, and obtain flower spherical niobium-doped bismuth oxybromide.

[0033] Specifically: S1. Heat 5-90 mL of diethylene glycol, triethylene glycol, isopropanol, ethylene glycol or glycerol as an alcohol solvent to boiling, and then cool to 40-80°C; the alcohol solvent Including diethylene glycol, triethylene glycol, isopropanol, ethylene glycol or glycerol, etc.

[0034] S2. Add 0.1 to 1.5g of bismuth salt compound, 0.001 to 0.05g of niobium compound and 0.02 to 0...

Embodiment 1

[0040] Heat 20mL of ethylene glycol to boiling, then stop heating and allow the solution to cool naturally to 60°C, add 0.485g of bismuth nitrate pentahydrate, 0.0068g of niobium oxalate hydrate and 0.1024g of 2-ethylamine hydrobromide to the ethylene glycol solution , mixed and fully stirred for 30 minutes, then 60 mL of isopropanol was added, and then continued to be fully stirred for 30 minutes, and the resulting mixed solution was put into a high-pressure reactor with a pressure of 1-2 MPa, and reacted at a constant temperature of 120 ° C for 12 hours. After the reaction solution was cooled to room temperature, the solution was separated, washed three times with water and ethanol solution respectively, dried at 60°C for 12 hours, and the resulting powder was collected to obtain the final product niobium-doped bismuth oxybromide (Nb-BiOBr) .

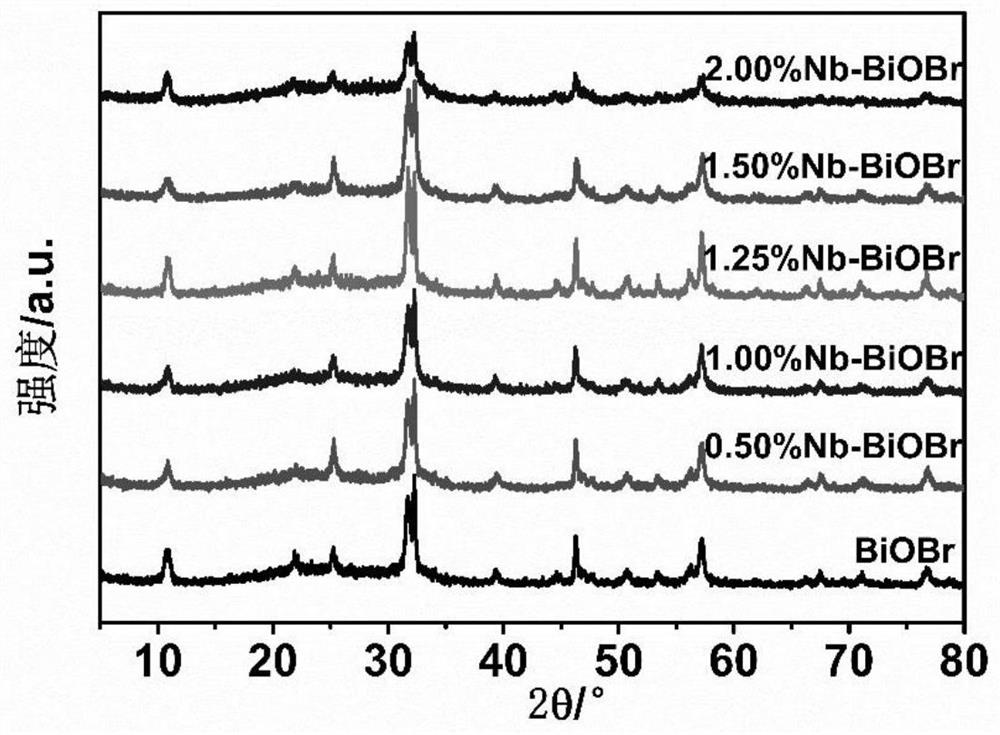

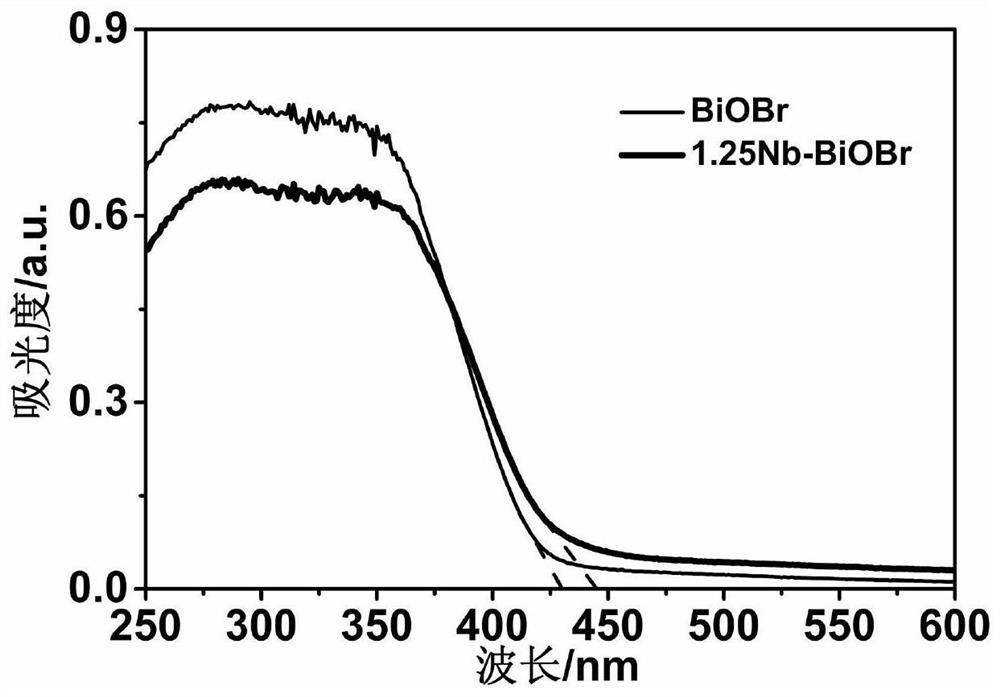

[0041] figure 1 It is the XRD diffraction pattern of the Nb-BiOBr photocatalyst obtained in this example, and compared with the PDF...

Embodiment 2

[0048] Heat 20mL of ethylene glycol to boiling, then stop heating and allow the solution to cool naturally to 60°C, add 0.485g of bismuth nitrate pentahydrate, 0.0027g of niobium oxalate hydrate and 0.1024g of 2-ethylamine hydrobromide to the ethylene glycol solution , mixed and fully stirred for 30 minutes, then 60 mL of isopropanol was added, and then continued to be fully stirred for 30 minutes, and the resulting mixed solution was put into a high-pressure reactor with a pressure of 1-2 MPa, and reacted at a constant temperature of 120 ° C for 12 hours. After the reaction solution was cooled to room temperature, the solution was separated, washed three times with water and ethanol solution respectively, dried at 60°C for 12 hours, and the resulting powder was collected to obtain the final product niobium-doped bismuth oxybromide (Nb-BiOBr) .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com