Rare earth ion doped silicon oxynitride-based fluorescent powder, preparation method thereof and combustion synthesis device

A technology based on silicon oxynitride and rare earth ions, which is applied in chemical instruments and methods, luminescent materials, chemical/physical processes, etc., can solve the problems of low purity of synthetic products, unsuitable base phosphors, low utilization rate of raw materials, etc. Achieve the effects of short preparation time, uniform powder particle size distribution, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

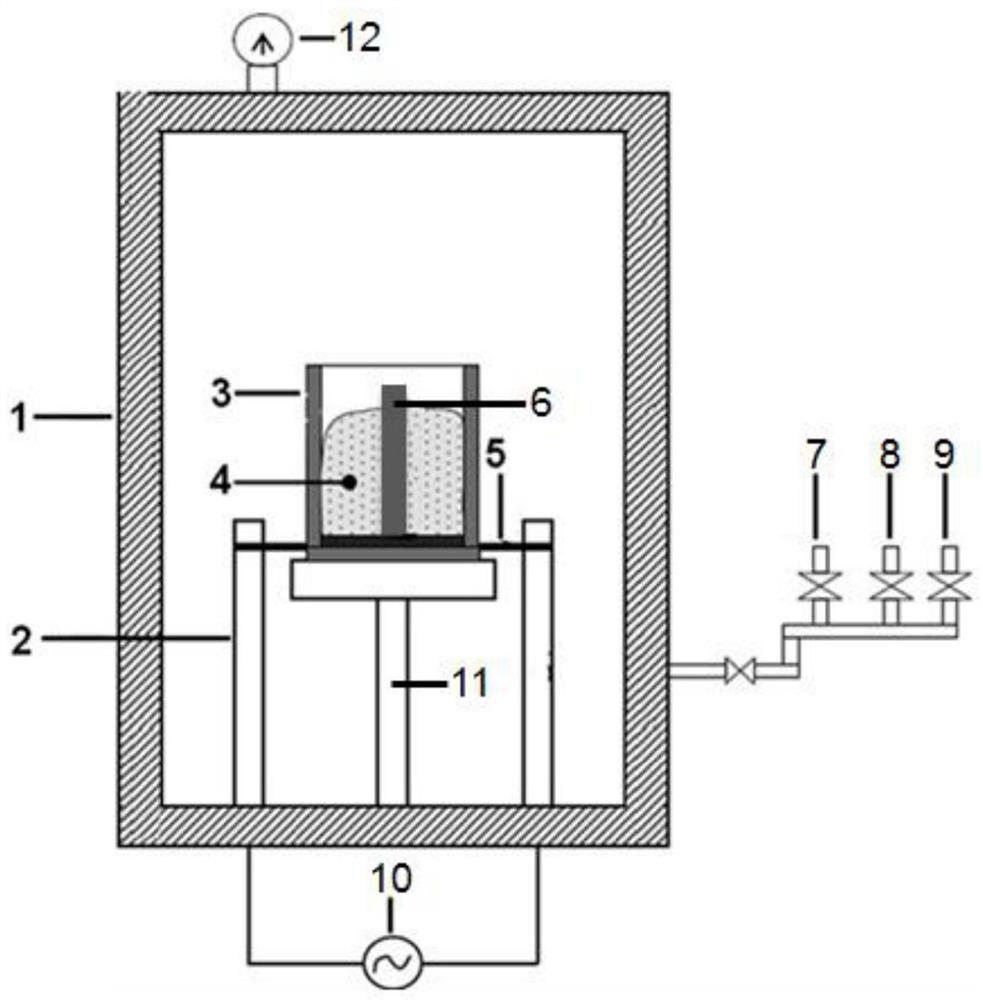

Embodiment 1

[0035] According to the chemical formula Si (2-x) N 2 O:xRe(Re=Eu 2+ ), take x=0.01, Si:SiO 2 :Si 2 N 2 The molar ratio of O is 3:1:0.1, NH 4 The amount of Cl added is Si powder, SiO 2 Powder and Si 2 N 2 0.5% of the total mass of O powder, Eu 2 o 3 The amount of powder added is calculated according to the chemical formula. About 8.4 grams of Si powder, SiO 2 Powder 6 grams, Si 2 N 2 O powder 1g, NH 4 Cl powder 0.77g, Eu 2 o 3 0.7392 g of the powder was mixed and put into a ball mill tank for ball milling for 2 hours at a speed of 400 rpm, then dried at 80° C. for 8 hours and passed through a 100-mesh sieve. Put the pre-reaction powder 4 into the porous graphite crucible 3 containing the graphite rod 6, and put it into the reaction chamber 1 of the high-pressure combustion synthesis device. After the reaction chamber is evacuated until the air pressure is less than 10Pa, it is filled with 2.0MPa high-purity nitrogen gas with a purity of 99.999%. ignited by the...

Embodiment 2

[0038] According to the chemical formula Si (2-x) N 2 O:xRe(Re=Ce 3+ ), take x=0.005, Si:SiO 2 :Si 2 N 2 The molar ratio of O is 3:1:0.2, NH 4 The amount of Cl added is Si powder, SiO 2 Powder and Si 2 N 2 2% of the sum of the total mass of O powder, Ce 2 o 3 The amount of powder added is calculated according to the chemical formula. About 8.4 grams of Si powder, SiO 2 Powder 6 grams, Si 2 N 2 O powder 2 grams, NH 4 Cl powder 0.328g, Ce 2 o 3 0.3608 g of the powder was mixed and put into a ball mill jar for ball milling for 2 hours at a speed of 400 rpm, then dried at 80° C. for 8 hours and passed through a 100-mesh sieve. Put the pre-reaction powder 4 into the porous graphite crucible 3 containing the graphite rod 6, and put it into the reaction chamber 1 of the high-pressure combustion synthesis device. After the reaction chamber is evacuated until the air pressure is less than 10Pa, it is filled with 4.0MPa high-purity nitrogen gas with a purity of 99.999%. ...

Embodiment 3

[0040] According to the chemical formula Si (2-x) N 2 O:xRe(Re=Eu 2+ ), take x=0.001, Si:SiO 2 :Si 2 N 2 The molar ratio of O is 3:1:0, NH 4 The amount of Cl added is Si powder, SiO 2 Powder and Si 2 N 2 5% of the total mass of O powder, Eu 2 o 3 The amount of powder added is calculated according to the chemical formula. About 8.4 grams of Si powder, SiO 2 Powder 6 grams, NH 4 Cl powder 0.72g, Eu 2 o 3 0.0352 g of the powder was mixed and put into a ball mill tank for ball milling for 2 hours at a speed of 400 rpm, then dried at 80° C. for 8 hours and passed through a 100-mesh sieve. Put the pre-reaction powder 4 into the porous graphite crucible 3 containing the graphite rod 6, and put it into the reaction chamber 1 of the high-pressure combustion synthesis device. After the reaction chamber is evacuated until the air pressure is less than 10Pa, it is filled with 1.0MPa high-purity nitrogen gas with a purity of 99.999%. ignited by the bottom of the powder throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com