Preparation method and application of calcium aluminate catalyst capable of regulating olefin selectivity

A calcium aluminate, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high cracking reaction temperature, lack of pore structure, and large specific gravity, and achieve light oil Improved yield, mild preparation conditions, and small loss of light oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

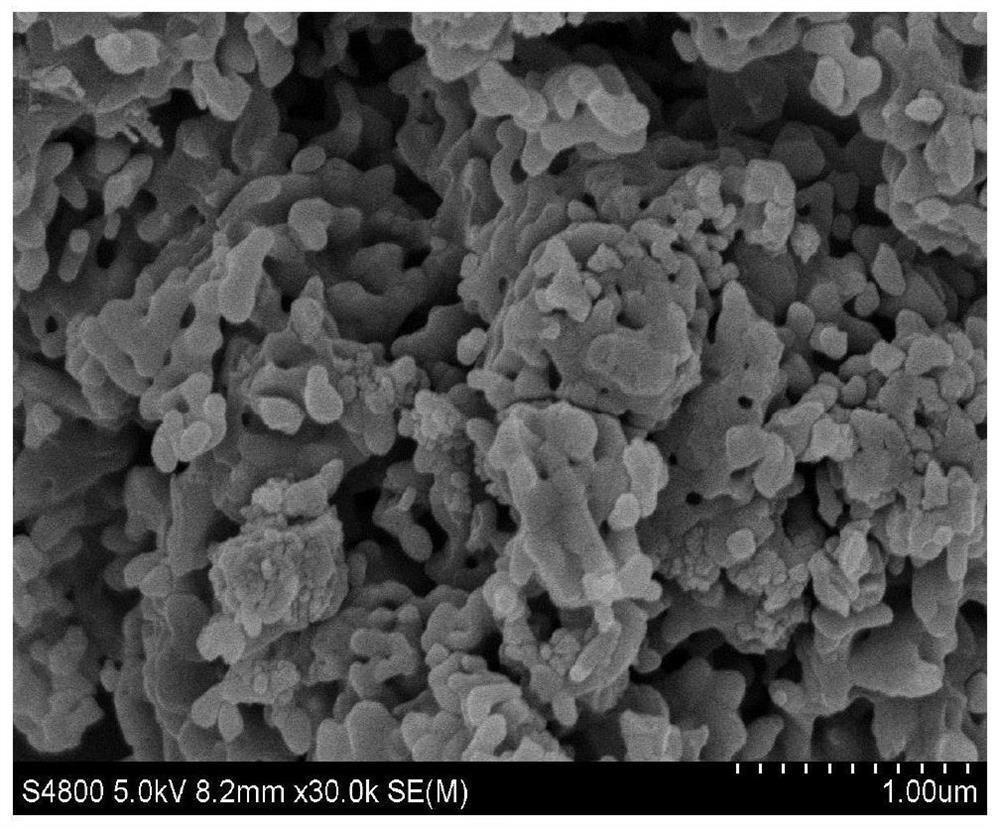

Image

Examples

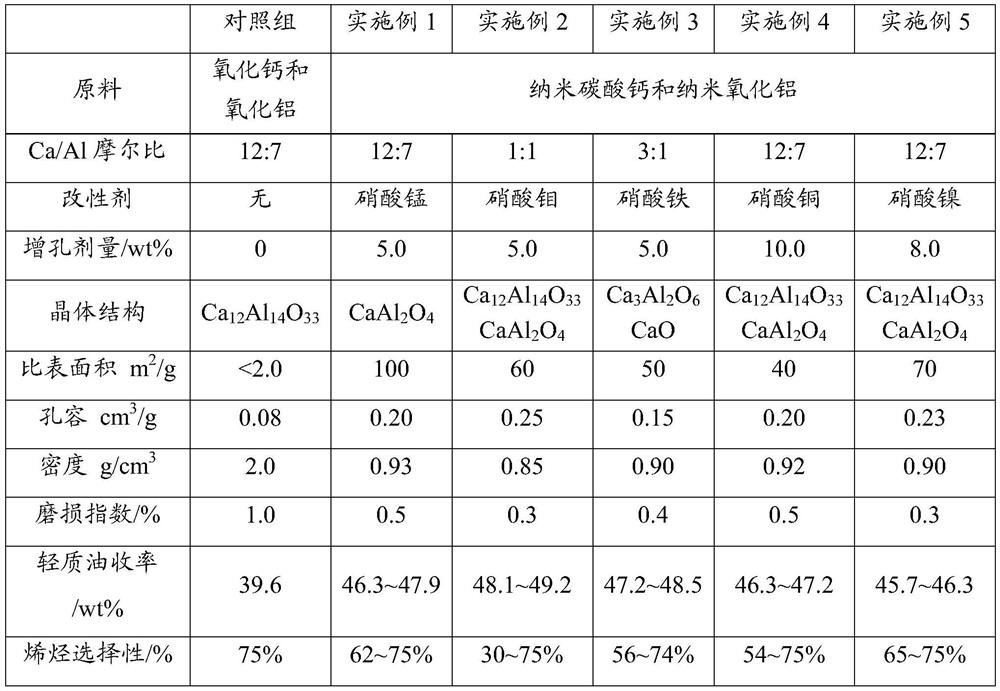

Embodiment 1

[0030] A method for preparing a calcium aluminate catalyst capable of regulating olefin selectivity, comprising the following steps:

[0031] S1. Stir and mix nano-calcium carbonate and nano-alumina in a molar ratio of 12:7 in a mixed solvent of water and ethanol in a volume ratio of 1:0.5, and then add 5.0wt% pore-enhancing agent carbon black Mix with cetyltrimethylammonium bromide evenly to obtain a mixed slurry;

[0032] S2. The mixed slurry obtained in S1 was raised from room temperature to 300°C at a heating rate of 5.0°C / min under an inert gas atmosphere, and kept at this temperature for 1.5h, and then raised to 300°C at a heating rate of 5.0°C / min. 800°C, and then increase the temperature from 800°C to 900°C at a rate of 1.0°C / min, so that the porogen slowly pyrolyzes the raw coke and slowly decomposes the calcium carbonate powder;

[0033] Then, at a heating rate of 5.0°C / min, continue to heat up to 950°C for 4.5h;

[0034] Then it is placed in a mixed gas atmosphere...

Embodiment 2

[0037] A method for preparing a calcium aluminate catalyst capable of regulating olefin selectivity, comprising the following steps:

[0038] S1. Mix nano-calcium carbonate and nano-alumina in a molar ratio of 1:1 in a mixed solvent mixed with water and ethanol in a volume ratio of 1:1, and then add 5.0wt% pore-enhancing agent carbon black Mix with cetyltrimethylammonium bromide evenly to obtain a mixed slurry;

[0039] S2. The mixed slurry obtained in S1 was raised from room temperature to 300°C at a heating rate of 5.0°C / min under an inert gas atmosphere, and kept at this temperature for 1.5h, and then raised to 300°C at a heating rate of 5.0°C / min. 800°C, and then increase the temperature from 800°C to 900°C at a rate of 1.0°C / min, so that the porogen slowly pyrolyzes the raw coke and slowly decomposes the calcium carbonate powder;

[0040] Then, at a heating rate of 5.0°C / min, continue to heat up to 950°C for 4.5h;

[0041] and then placed in a mixed gas atmosphere compo...

Embodiment 3

[0044] A method for preparing a calcium aluminate catalyst capable of regulating olefin selectivity, comprising the following steps:

[0045] S1. Stir and mix nano-calcium carbonate and nano-alumina in a molar ratio of 3:1 in a mixed solvent of water and ethanol in a volume ratio of 1:2, and then add 5.0wt% pore-enhancing agent carbon black Mix with cetyltrimethylammonium bromide evenly to obtain a mixed slurry;

[0046] S2. The mixed slurry obtained in S1 was raised from room temperature to 300°C at a heating rate of 5.0°C / min under an inert gas atmosphere, and kept at this temperature for 1.5h, and then raised to 300°C at a heating rate of 5.0°C / min. 800°C, and then increase the temperature from 800°C to 900°C at a rate of 1.0°C / min, so that the porogen slowly pyrolyzes the raw coke and slowly decomposes the calcium carbonate powder;

[0047] Then, at a heating rate of 5.0°C / min, continue to heat up to 950°C for 4.5h;

[0048] and then placed in a mixed gas atmosphere comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com