Preparation method and application of sodium vanadyl fluorophosphate/graphene composite electrode material

The technology of sodium vanadyl fluorophosphate and sodium vanadyl phosphate is applied in the field of high energy electrochemistry, which can solve the problems of common ion efficiency affecting charge efficiency, adsorption capacity effect, electrode oxidation, etc., achieving no secondary pollution and high adsorption rate. , the effect of large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

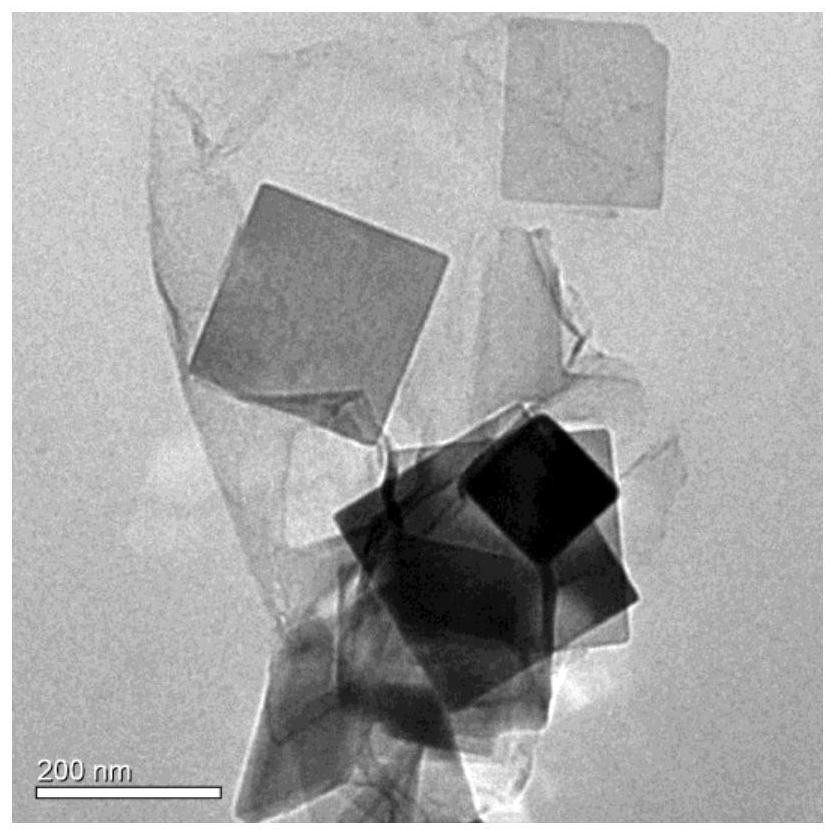

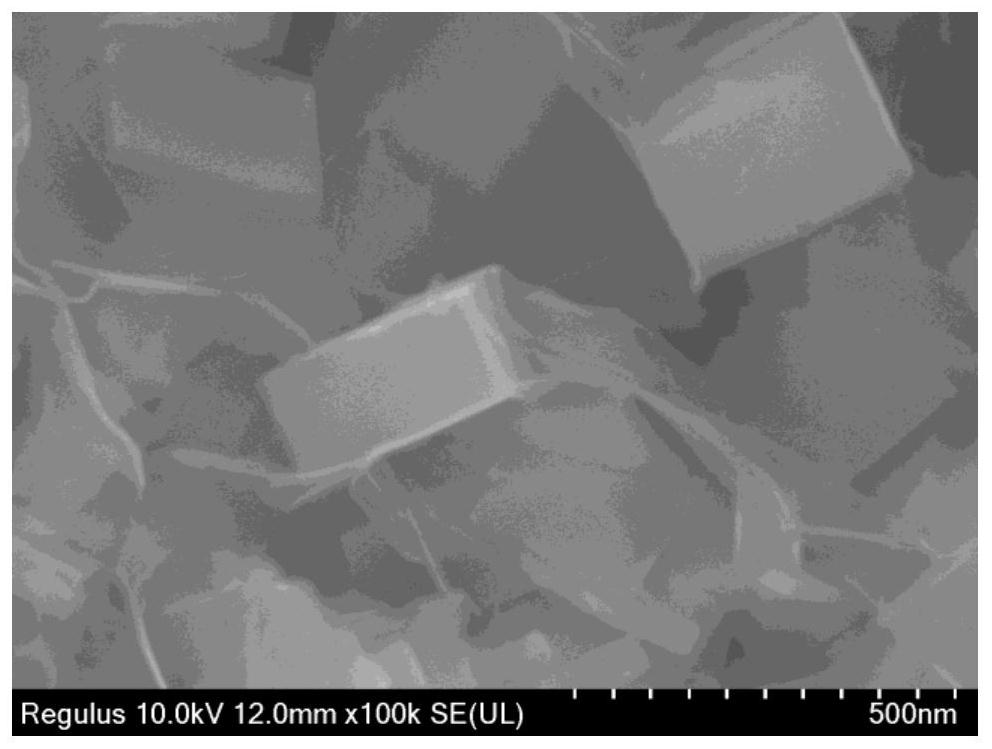

[0045] Preparation of sodium vanadyl fluorophosphate / graphene composite:

[0046] (1) Dissolve 1g of graphite oxide in a neutral aqueous solution, and move it into a 250ml volumetric flask, and form a uniform aqueous solution of graphene oxide by stirring and ultrasonication for 300min, wherein the concentration of graphene oxide is 4g L -1 ;

[0047] (2) Weigh ammonium dihydrogen phosphate, ammonium vanadate, sodium carbonate, and sodium fluoride to be 0.46g, 0.468g, 0.212g,

[0048]0.084g added to 8mL concentration is 4g L -1 A stable solution A is formed in the graphene solution;

[0049] (3) Put the solution A obtained in step (2) on a magnetic stirrer, add 40 mL of N,N-dimethylformamide dropwise, adjust the pH to 7 with nitric acid, transfer it to a hydrothermal kettle, and After heating for 10 hours, the obtained product was washed with deionized water and ethanol, and dried in a vacuum oven to obtain a black powder that was sodium fluorovanadyl phosphate / graphene com...

Embodiment 2

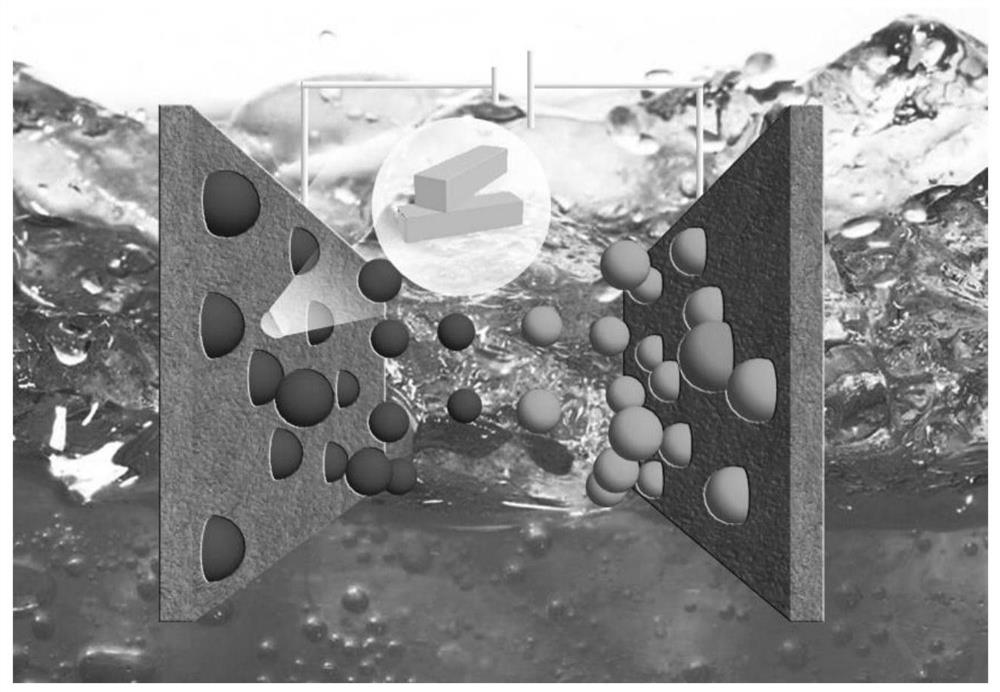

[0054] This example adopts the application of the sodium vanadyl fluorophosphate / graphene composite material prepared in Example 1 in the hybrid capacitive deionization technology.

[0055] Preparation of sodium vanadyl fluorophosphate / graphene electrode and activated carbon electrode:

[0056] Based on the sodium vanadyl fluorophosphate / graphene composite material prepared in Example 1, the sodium vanadyl fluorophosphate / graphene composite material and activated carbon were mixed with PVDF and acetylene black according to the mass ratio of 8:1:1, respectively. Stir the NMP for about 6 hours to obtain a uniformly mixed slurry, apply the slurry on the graphite paper collector, and dry it in vacuum at 60°C to obtain amorphous carbon-coated sodium vanadium phosphate electrodes and activated carbon electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com