Chelated nano-iron water area purification ball and preparation method thereof

A purification ball and nano-iron technology, which is applied in chemical instruments and methods, special compound water treatment, biological water/sewage treatment, etc., can solve the problems that are not conducive to the colonization of bacterial agents, and the purification effect is not durable, so as to enhance the water quality purification function , quick effect and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A chelated nano-iron water area purification ball, in terms of mass percentage, the purification ball is composed of 5% solid probiotic bacterial agent, 93% river mud and 2% probiotic propagation liquid;

[0032] The solid probiotic bacterial agent is composed of 20% rice bran, 15% wheat bran, 10% soybean meal, 5% probiotic propagation liquid, 1% molasses, 5% nano-iron powder and the rest of water. To the sealed fermentation equipment, fermented at 30°C for 2 weeks, after the fermentation is finished, the sour aroma is strong and the solid probiotic bacterial agent is obtained;

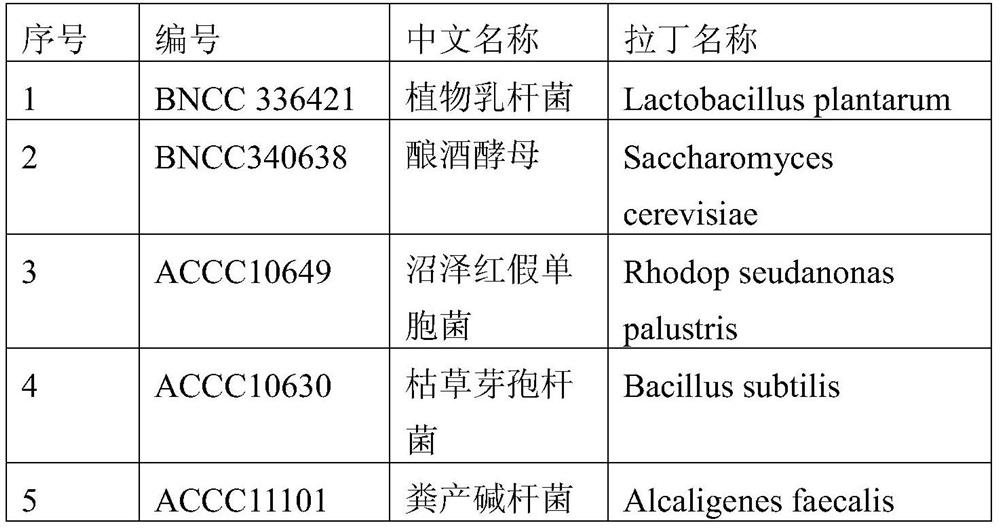

[0033] The preparation method of the probiotic proliferation liquid: by mass percentage, 5% of domestic sewage, 10% of probiotics, 5% of molasses, and the remaining water are placed in a closed fermentation equipment, and cultivated at an ambient temperature of 25°C for 7 days. Pay attention to degassing in the medium, and the fermentation ends after the pH reaches below 4.0, the odor of sewage...

Embodiment 2

[0038] A chelated nano-iron water area purification ball, in terms of mass percentage, the purification ball is composed of 7% solid probiotic bacterial agent, 92% river mud and 1% probiotic propagation liquid;

[0039]The solid probiotic bacterial agent, in terms of mass percentage, consists of 40% rice bran, 10% wheat bran, 16% soybean meal, 5% probiotic propagation liquid, 3% molasses, 10% nano-iron powder, and the rest of water. To the sealed fermentation equipment, fermented at 31°C for 2 weeks, after the fermentation is finished, the sour aroma is strong to obtain the solid probiotic bacterial agent;

[0040] The preparation method of the probiotic proliferation liquid: by mass percentage, 10% of domestic sewage, 5% of probiotics, 8% of molasses, and the remaining water are placed in a closed fermentation equipment, and cultivated at an ambient temperature of 37°C for 6 days. Pay attention to degassing in the medium, and the fermentation ends after the pH reaches below 4...

Embodiment 3

[0045] A chelated nano-iron water area purification ball, in terms of mass percentage, the purification ball is composed of 6% solid probiotic bacterial agent, 92% river mud and 2% probiotic propagation liquid;

[0046] The solid probiotic bacterial agent is composed of 40% of rice bran, 15% of wheat bran, 16% of soybean meal, 1% of probiotic propagation liquid, 1% of molasses, 5% of nano-iron powder, and the rest of water. To the sealed fermentation equipment, fermented at 33 ° C for 2 weeks, after the fermentation is finished, the sour aroma is strong to obtain the solid probiotic bacterial agent;

[0047] The preparation method of the probiotic propagation liquid: according to the mass percentage, 10% of domestic sewage, 5% of probiotics, 5% of molasses, and the remaining water are placed in a closed fermentation equipment, and cultivated at an ambient temperature of 27°C for 7 days. Pay attention to degassing in the medium, and the fermentation ends after the pH reaches be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com