B-P co-doped double-transition metal catalyst as well as preparation method and application thereof

A technology of transition metals and transition metal elements, applied in the field of B-P co-doped transition metal catalysts and its preparation, can solve the problems of low catalytic efficiency, high reaction energy, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

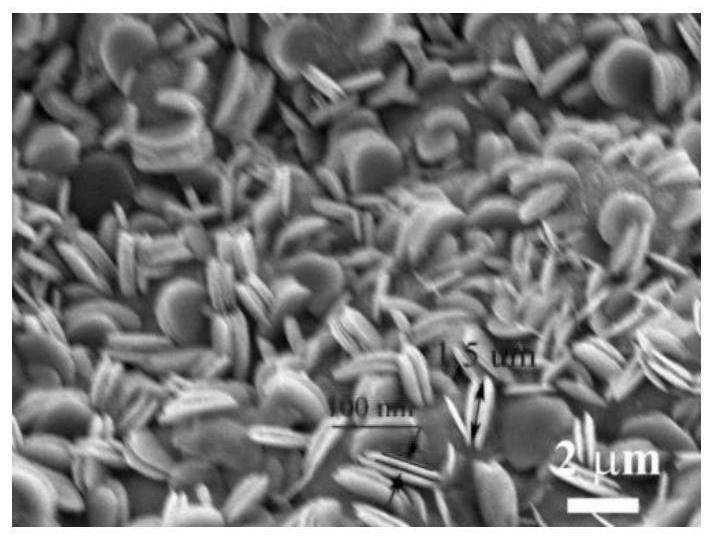

[0030] Preparation of Co-Mo-B-P / CF catalyst:

[0031] (1) First, pretreat the carrier: soak the carrier foam copper in ethanol solution for 5 minutes, put the cleaned foam copper in a solution of 0.01mol / L dilute hydrochloric acid for 2 minutes, and then put it into deionized Ultrasonic vibration in water for 10 minutes, placed in an oven at 50°C, dried and weighed for later use;

[0032] (2) Prepare 100ml of 1moL / l sodium molybdate dihydrate, cobalt chloride, sodium hypophosphite, boric acid, and trisodium citrate solutions respectively; select the graphite plate as the anode, pass 5 solutions into the electroplating tank, and control The concentration of the plating solution in the electroplating tank is respectively: the concentration of sodium molybdate dihydrate solution is 0.15mol / L, the concentration of sodium hypophosphite solution is 0.3mol / L, the concentration of boric acid is 0.3mol / L, and the concentration of trisodium citrate is 25g / L, and the concentration of co...

Embodiment 2

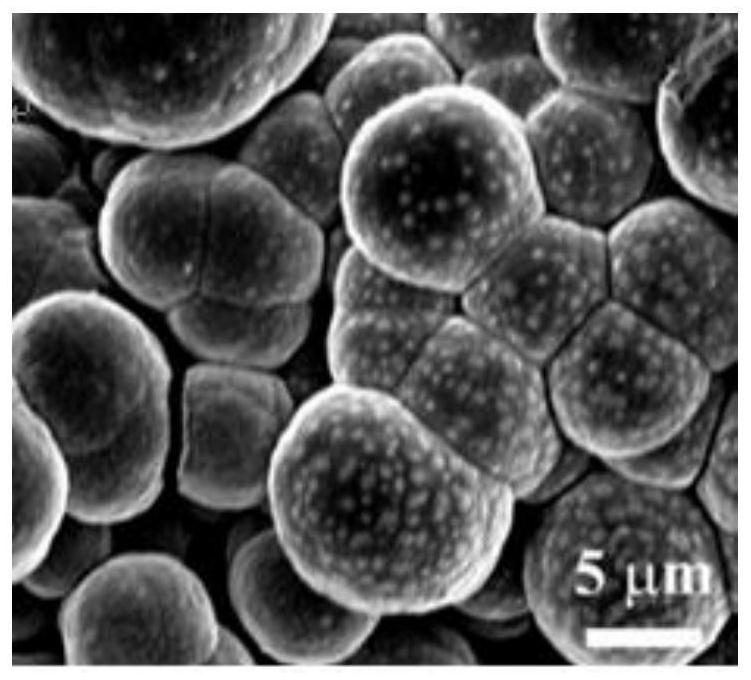

[0041] The difference between this embodiment and embodiment 1 is: the carrier is nickel foam; the plating solution consists of: cobalt chloride hexahydrate, anhydrous ferric chloride, sodium hypophosphite monohydrate, boric acid and trisodium citrate dihydrate, Concentrations are 0.15mol / L, 0.1mol / L, 0.35mol / L, 0.4mol / L, 17.5g / L; electroplating parameters are electroplating time of 12min, forward / reverse average current density of 0.35 / 0.135A / cm 2 , the forward / reverse pulse duty ratio is 70% / 60%, the number of forward / reverse pulses is 7:1, the temperature of the mixed plating solution is 60°C, and the pH of the mixed plating solution is 6, and the Co-Fe-B-P / CF catalyst is obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com