Graphene/MXene composite fiber flexible electrode material based on solid electrolyte and preparation method of knittable supercapacitor

A solid electrolyte and composite fiber technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of sacrificial electrode conductivity and unsatisfactory application of high-performance supercapacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

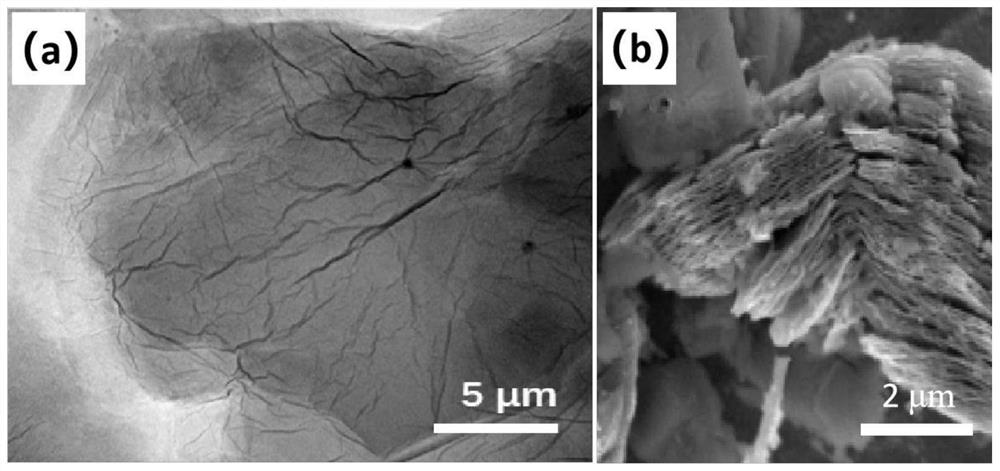

[0056] (2) Preparation of graphene oxide: Graphene oxide is prepared by the modified Hummers method, specifically: ① Low-temperature oxidation: take concentrated sulfuric acid and sodium nitrate with a mass ratio of (0.1~1): (10~60) in a beaker , Mechanical stirring at 0~8℃. Then add the expanded graphite prepared in step S1 slowly, then add 2-10g potassium permanganate, stir vigorously for 0.1-2h; ②Medium temperature oxidation: increase the temperature of the magnetic stirrer to 30-50℃ and stir for 0.1-1.5h , Slowly add 50~150ml distilled water dropwise during the reaction; ③High temperature oxidation: increase the temperature of the magnetic stirrer to 70~100℃, and at the same time, after the process of heating, add 100~300mL deionized water and 1~8ml 30% The hydrogen peroxide solution is mechanically stirred, and when the color of the solution changes from brown to bright yellow, the prepared graphene oxide solution is obtained. Afterwards, in order to remove the metal oxid...

Embodiment 1

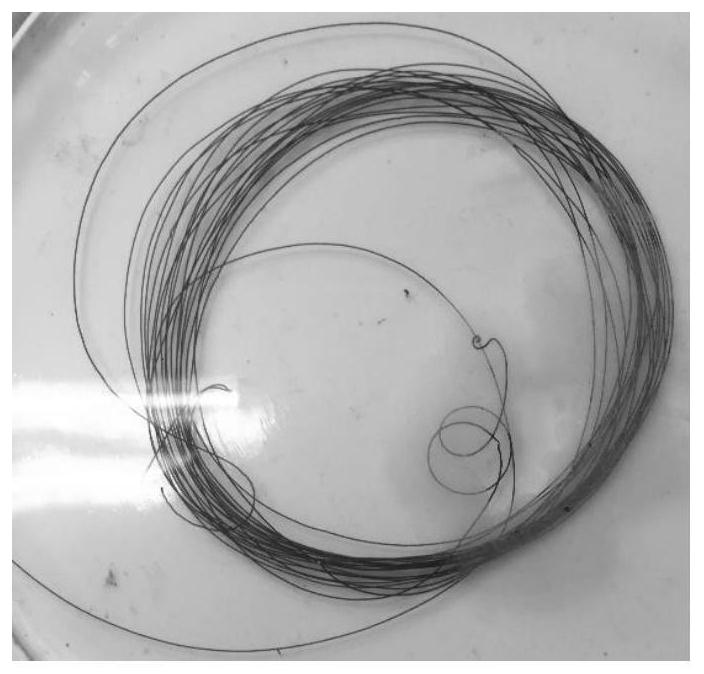

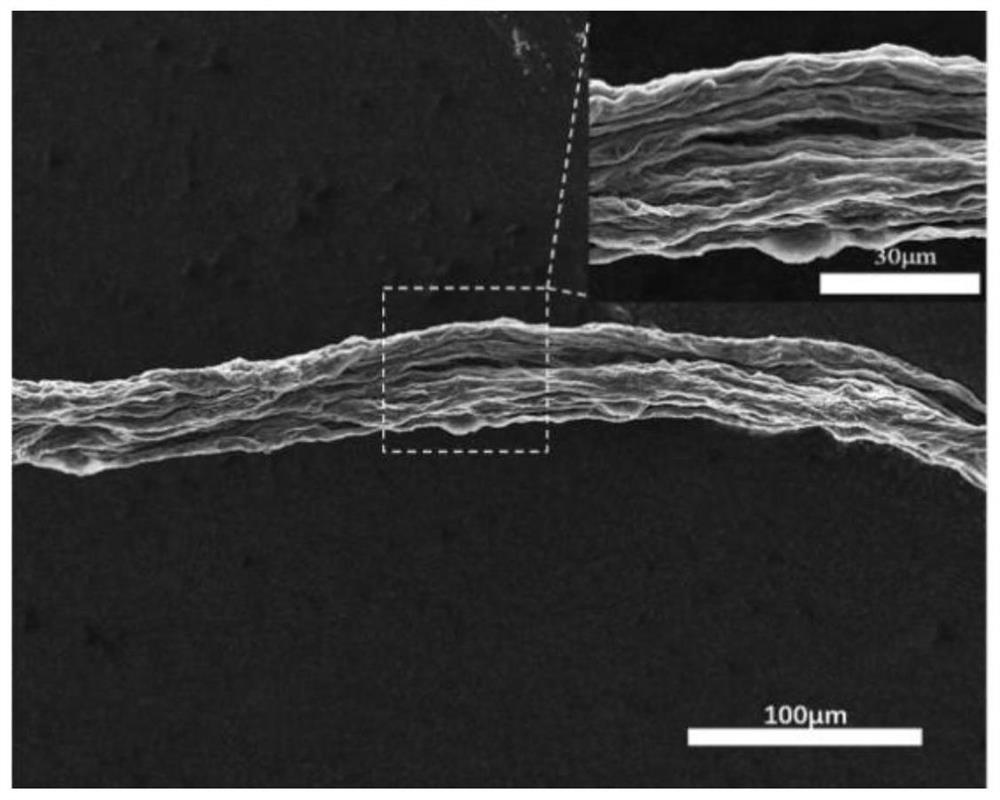

[0074] Preparation of solid electrolyte graphene / MXene flexible fiber electrode material and supercapacitor

[0075] Step 1: Preparation of expanded graphite: Take 2-8g of concentrated sulfuric acid (98% by mass) and 1-4g of concentrated nitric acid into a beaker, mix and stir with a glass rod. Take 0.1-2g graphite powder and 0.1-2g potassium permanganate slowly add to the mixture. Use a circulating water multipurpose vacuum pump to suction and filter the mixture several times to a pH of 6-7, and then put the product after suction filtration into a vacuum drying oven at 40-80°C to dry to powder. Put the crucible into the muffle furnace and heat it to 700~1000℃, then take it out with crucible tongs, quickly add the dried powder to the crucible and cover the lid (to prevent the expansion of graphite from splashing), and after natural cooling at room temperature, the expanded graphite is obtained .

[0076] Step two, preparation of graphene oxide nanosheets: the modified Hummers met...

Embodiment 2

[0088] Preparation of solid electrolyte graphene / MXene flexible fiber electrode material and supercapacitor

[0089] Step 1: Preparation of expanded graphite: Take 2-8g of concentrated sulfuric acid (98% by mass) and 1-4g of concentrated nitric acid into a beaker, mix and stir with a glass rod. Take 0.1-2g graphite powder and 0.1-2g potassium permanganate slowly add to the mixture. Use a circulating water multipurpose vacuum pump to suction and filter the mixture several times to a pH of 6-7, and then put the product after suction filtration into a vacuum drying oven at 40-80°C to dry to powder. Put the crucible into the muffle furnace and heat it to 700~1000℃, then take it out with crucible tongs, quickly add the dried powder to the crucible and cover the lid (to prevent the expansion of graphite from splashing), and after natural cooling at room temperature, the expanded graphite is obtained .

[0090] Step 2: Preparation of graphene oxide nanosheets: The modified Hummers metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com