Preparation method of cobamamide crude product

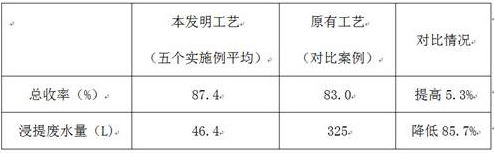

A technology for adenosylcobalamin and crude product, which is applied in the field of preparation of crude adenosylcobalamin, can solve the problems of generating a lot of waste water, affecting the continuity of operations, and many times of dismantling and washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 15kg of adenosylcobalamin mycelium powder (containing 0.029kg of adenosylcobalamin), put it into a solvent extraction tank, and add acetone to compound Solvent (acetone (v): isopropanol (v): water (v) = 3.5:1.5:5.5), control the stirring speed at 60rpm, and carry out leaching at room temperature. After leaching for 3 hours, filter in a centrifuge and collect the filter residue. Carry out the second leaching as before, combine the two extracts, and concentrate under reduced pressure with a thin-film evaporator to obtain adenosylcobalamin concentrated solution I 39L (potency 718 μg / ml), with a yield of 96.6%.

[0028] Put the above adenosylcobalamin concentrated solution I into the macroporous resin adsorption column, and then use 30% (v / v), 40% (v / v), 50% (v / v) acetone aqueous solution to analyze in sequence, and collect the analysis solution , concentrated under reduced pressure with a thin-film evaporator to obtain adenosylcobalamin concentrate II 75L (titer 358μg...

Embodiment 2

[0032] Take 15kg of adenosylcobalamin mycelium powder (containing 0.029kg of adenosylcobalamin), put it into a solvent extraction tank, and add acetone to compound Solvent (acetone (v): isopropanol (v): water (v) = 4.0:1.7:6.0), control the stirring speed at 60rpm, carry out leaching at room temperature, after leaching for 3 hours, filter in a centrifuge, collect the filter residue, Carry out the second leaching as before, combine the two extracts, concentrate under reduced pressure to obtain 43 L of extract concentrate, the concentration of the concentrate is 660 μg / ml, and the yield is 97.9%.

[0033] Put the above adenosylcobalamin concentrated solution I into the macroporous resin adsorption column, and then use 30% (v / v), 40% (v / v), 50% (v / v) acetone aqueous solution to analyze in sequence, and collect the analysis solution , concentrated under reduced pressure with a thin film evaporator to obtain adenosylcobalamin concentrate II 79L (titer 350μg / ml), yield 97.4%.

[00...

Embodiment 3

[0037]Take 15kg of adenosylcobalamin mycelium powder (containing 0.029kg of adenosylcobalamin), put it into a solvent extraction tank, and add acetone to compound Solvent (acetone (v): isopropanol (v): water (v) = 4.5:2.0:6.5), control the stirring speed at 60rpm, carry out leaching at room temperature, after leaching for 3 hours, filter in a centrifuge, collect the filter residue, Carry out the second leaching as before, combine the three leaching liquids, and concentrate under reduced pressure to obtain 45 L of leaching concentrated liquid, the concentration of the concentrated liquid is 630 μg / ml, and the yield is 97.8%.

[0038] Put the above adenosylcobalamin concentrated solution I into the macroporous resin adsorption column, and then use 30% (v / v), 40% (v / v), 50% (v / v) acetone aqueous solution to analyze in sequence, and collect the analysis solution , concentrated under reduced pressure with a thin-film evaporator to obtain adenosylcobalamin concentrate II 81L (titer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com