Active bioglass-loaded skin regeneration material and preparation method thereof

A bioglass and skin regeneration technology, applied in medical science, non-woven fabrics, filament/thread forming, etc., can solve unfavorable wound cell adhesion, growth and differentiation, poor moisturizing effect, increase patient hospitalization time and infection risk, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

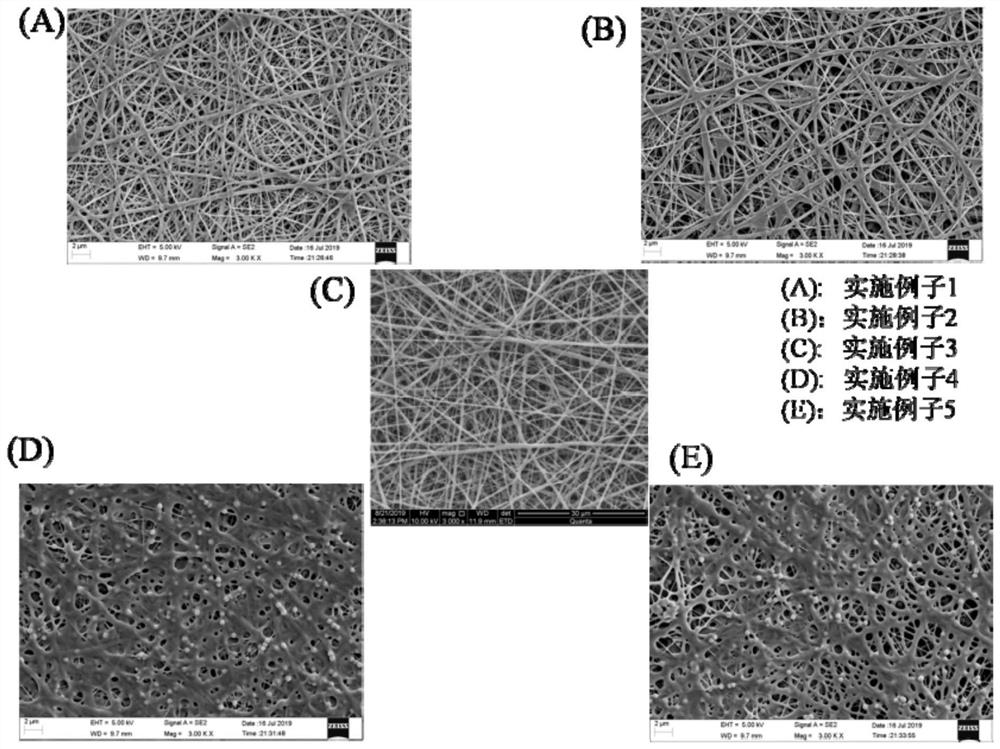

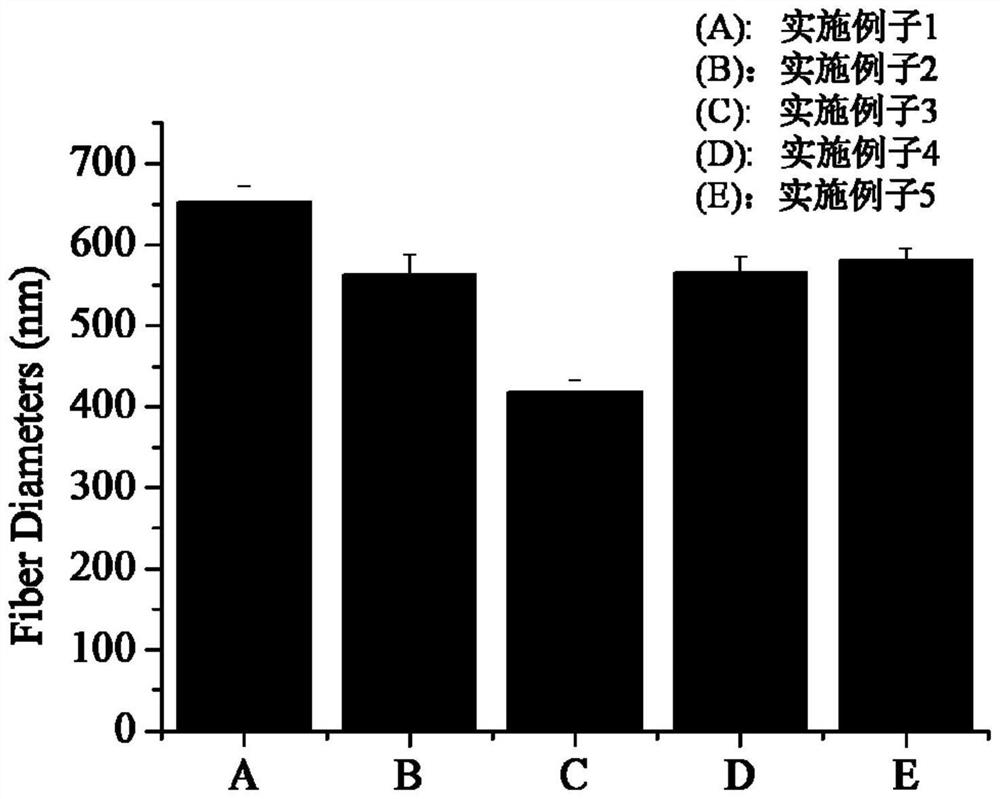

[0040] In Examples 1-10, the preparation method of the skin regeneration material comprises the following steps:

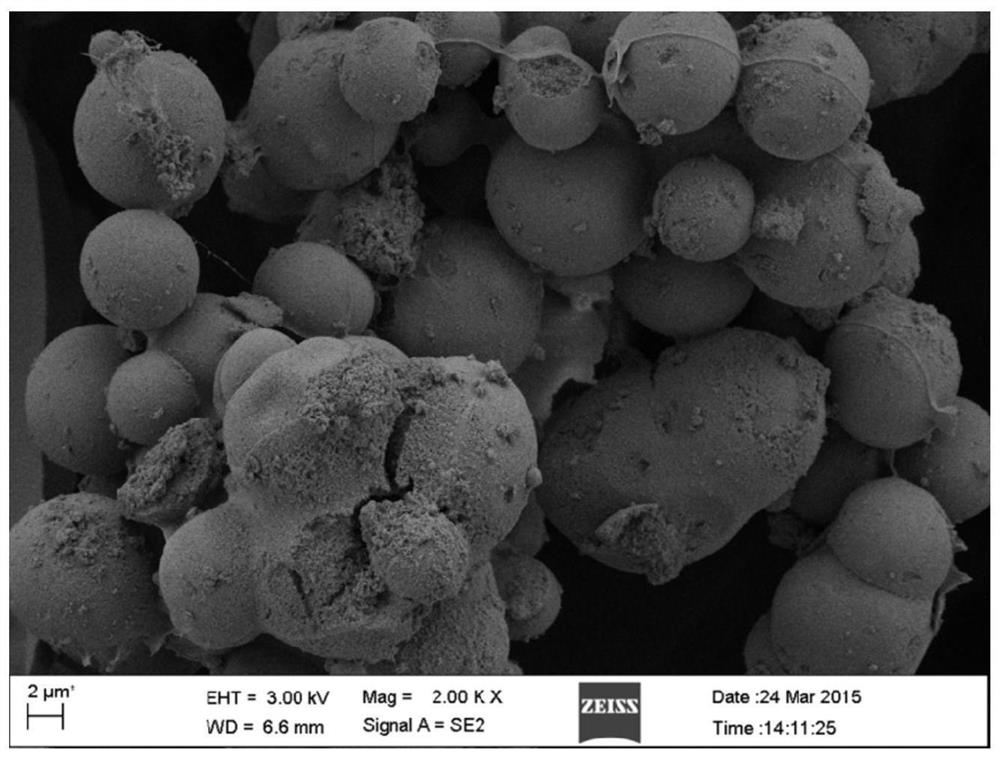

[0041] (1) Stir and mix silk fibroin, chitosan, polyvinyl alcohol, active biological glass and hexafluoroisopropanol at room temperature, and the stirring rate is 400rpm / 24h to obtain an electrospinning solution; the silk fibroin, The ratio of the quality of chitosan, polyvinyl alcohol and active biological glass is shown in Table 1, and the ratio of the sum of the quality of described silk fibroin, chitosan, polyvinyl alcohol and active biological glass to the volume of hexafluoroisopropanol is: 1:10;

[0042] (2) The electrospinning solution was spun with an electrospinning machine at a temperature of 40°C, a humidity of 35%, a voltage of 25kV, and a push rate of 2mL / h to prepare skin regeneration materials, and the spinning time was 4h. The skin regeneration material was obtained.

[0043] Wherein, the preparation method of silk fibroin comprises the followin...

Embodiment 5

[0054] Image 6 14 days after operation, the skin regeneration materials of different embodiments repair the rat wound. Depend on Image 6 It can be seen that after the skin regeneration material treatment of Example 4, the wound area has been greatly reduced, and the wound is almost completely repaired, which is the fastest recovery among the five experimental examples. However, in Example 5, there were still small wounds at the defect site. In contrast, in the experimental groups of Example 1, Example 2 and Example 3, the repair of the burn wound was relatively slow, the degree of wound healing was low and a small amount of pus was still visible at the wound.

[0055] Figure 7 with 8 14 days after operation, H&E and Masson staining of skin regeneration materials in different embodiments on rat wound repair. comprehensive Figure 7 with 8 It can be seen that 14 days after the operation, the levels of inflammatory cells in the tissues of Examples 4 and 5 were very low,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com