Preparation method of mesoporous carbon electrode and organic wastewater treatment equipment

A technology of organic wastewater treatment and mesoporous carbon, applied in water/sewage treatment equipment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the death of aquatic organisms, unfavorable biological treatment of wastewater, environmental pollution And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific preparation process of the porous carbon material electrode is as follows: first prepare RF sol (resorcinol-formaldehyde sol), dissolve 1g resorcinol and 0.018g sodium hydroxide in 20-30ml ethanol, then slowly add 2ml formaldehyde solution , magnetically stirred at room temperature for 50 min to obtain a light yellow sol. Then dissolve 0.50g of F127 in 20ml of ethanol solution, slowly add the above solution dropwise, and keep stirring for 50min, then introduce the solution into a watch glass at a temperature of 30°C for self-assembly, and then place it in an oven at 100°C to solidify the structure .

[0029] Mix the ordered mesoporous carbon material prepared above with the conductive agent and the adhesive in a mass ratio of 8:1:1, roll it into a thin sheet with a double-roller machine, and use a mold to press it to about 100×20×1 mm. The above film was shredded and heated in a tube furnace. The atmosphere was nitrogen during high-temperature carbonizatio...

Embodiment 2

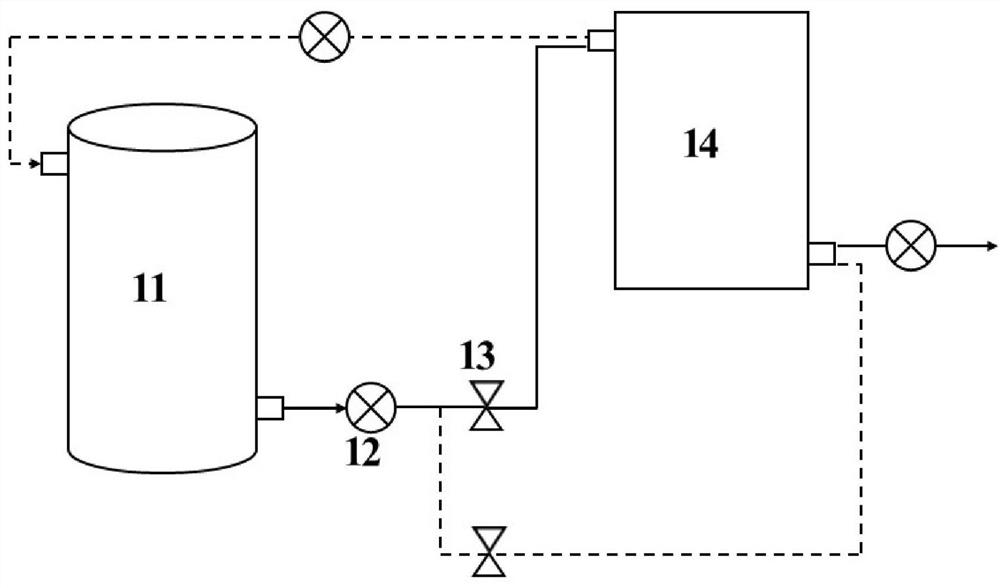

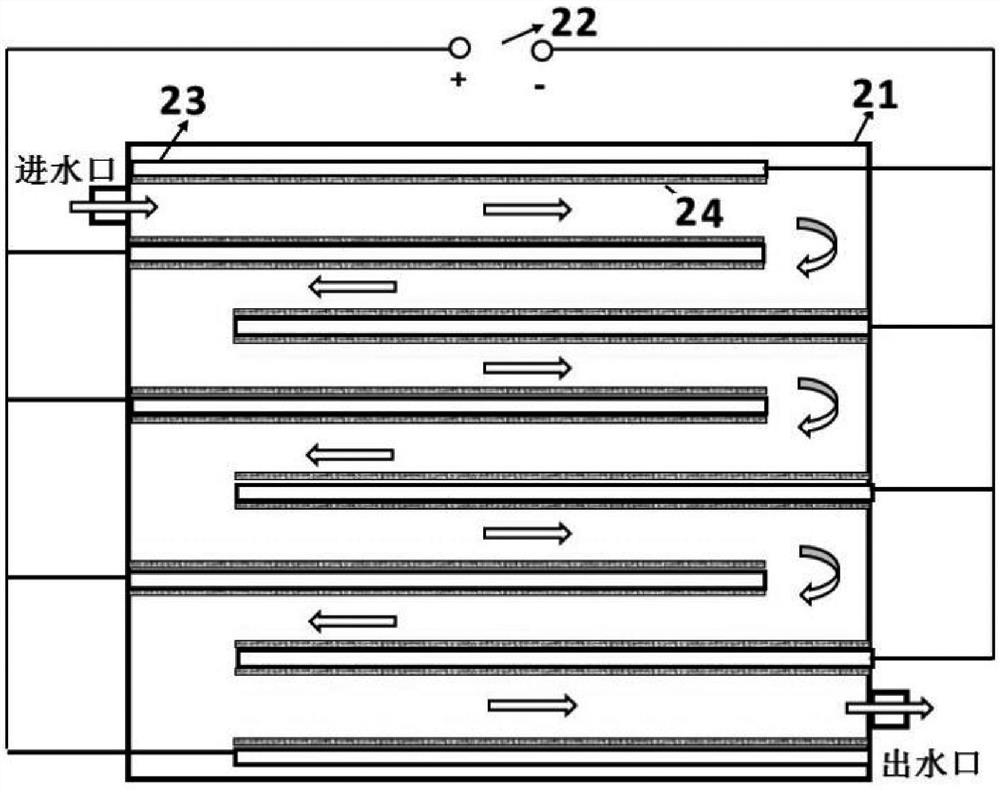

[0033] refer to figure 1 , figure 2 As shown, the high-salt organic wastewater treatment equipment based on mesoporous carbon electrodes includes a water storage tank 11 and an electro-adsorption regeneration device 14 connected to the water storage tank 11 through pipelines. The electro-adsorption regeneration device 14 includes an upper left set The water inlet, the plexiglass insulating shell 21 of the water outlet on the lower right, and a plurality of stainless steel conductive separating plates 23 arranged in parallel in the plexiglass insulating shell 21, the surface of the conductive separating plate 23 is adhered with a medium Porous carbon electrode 24, wherein the mesoporous carbon electrode 24 is a thin skin of 100 × 20 × 1 mm, the distance between two adjacent conductive separators 23 is 1 cm, and a group of conductive components fixed on the left side of the inner wall of the organic glass insulating shell 21 The dividing plate 23 is connected with the positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com