Method for rapidly preparing transition metal oxygen evolution catalyst by utilizing seawater

A transition metal and catalyst technology, applied in the field of electrocatalysis, can solve the problems of high overpotential and slow kinetics, and achieve the effects of low decomposition voltage, easy operation, and large seawater storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] S1. Perform coarse filtration pretreatment on the seawater, filter out the precipitated impurities, add 6g KCl to the beaker, take the filtered seawater and add it to the 100ml mark to prepare an electrolyte.

[0039] S2. Weigh 4g of discarded iron pieces, put them into 100mL of the above electrolyte, set the voltage window at 2.2V, and conduct electrolysis for 2 hours.

[0040] S3. Centrifuge the electrolyzed electrolyte solution for 4 minutes at a rotational speed of 5000 r / min, wash the centrifuged sediment several times with distilled water, and then dry it in an oven at a temperature of 50° C. for 5 hours.

[0041] S4. Soak the above-mentioned dried powder in 1mol / L KOH for 24 hours, and then dry the soaked powder in an oven at 70°C for 12 hours to obtain an iron-based catalyst, which is a mixture of iron oxide and iron hydroxide.

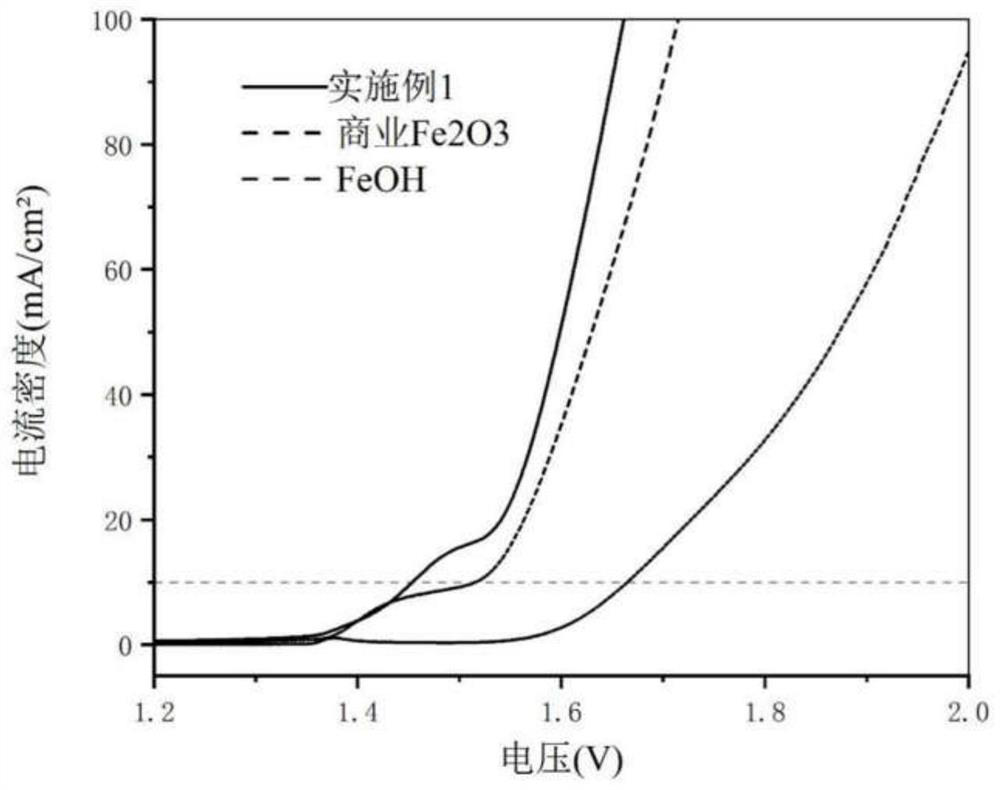

[0042] Depend on figure 1 The LSV can be seen at a current density of 10mAcm -2 , the oxygen evolution overpotential of the iron-bas...

Embodiment 2

[0044] S1. Perform coarse filtration pretreatment on seawater, filter out precipitated impurities, add 5g KBr into the beaker, take filtered seawater and add to 110ml mark line to prepare electrolyte.

[0045] S2. Weigh 7g of discarded nickel sheet, insert it into 110mL of the above electrolyte, set the voltage window at 2.4V, and conduct electrolysis for 0.5 hours.

[0046] S3. Centrifuge the electrolyzed electrolyte solution for 4 minutes at a rotational speed of 5000 r / min, wash the centrifuged sediment several times with distilled water, and then dry it in an oven at a temperature of 50° C. for 4 hours.

[0047] S4. Soak the dried powder in 1mol / L KOH for 24 hours, then dry the soaked powder in an oven at 70°C for 12 hours to obtain a nickel-based catalyst, which is a mixture of nickel oxide and nickel hydroxide.

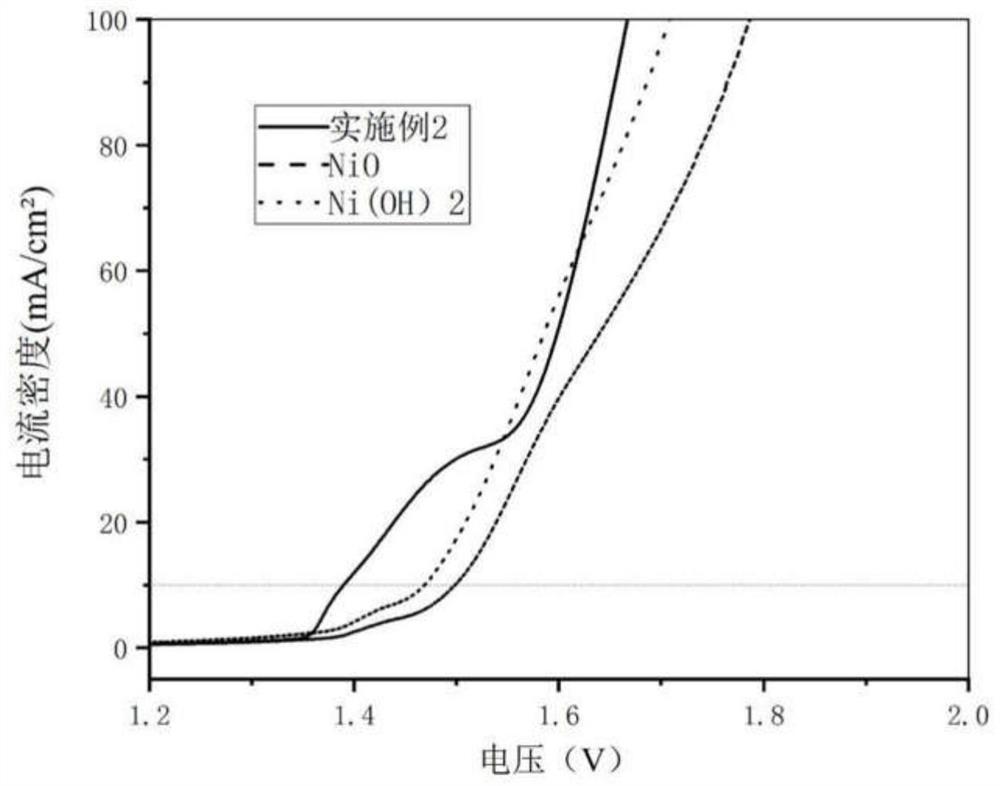

[0048] Depend on figure 2 The LSV can be seen at a current density of 10mAcm -2 , the oxygen evolution overpotential of the nickel-based catalyst was 168mV. ...

Embodiment 3

[0050] S1. Perform coarse filtration pretreatment on seawater, filter out precipitated impurities, add 3gKI into the beaker, take the filtered seawater and add it to the 80ml mark to prepare an electrolyte.

[0051] S2. Weigh 6g of waste cobalt flakes, put them into 80mL of the above electrolyte, set the voltage window at 1.5V, and conduct electrolysis for 1.5 hours.

[0052] S3. Centrifuge the electrolyzed electrolyte solution for 6 minutes at a rotational speed of 3000 r / min, wash the centrifuged sediment several times with distilled water, and then dry it in an oven at a temperature of 50° C. for 6 hours.

[0053] S4. Soak the dried powder in 1mol / L KOH for 24 hours, then dry the soaked powder in an oven at 70°C for 12 hours to obtain a cobalt-based catalyst, which is a mixture of cobalt oxide and cobalt hydroxide.

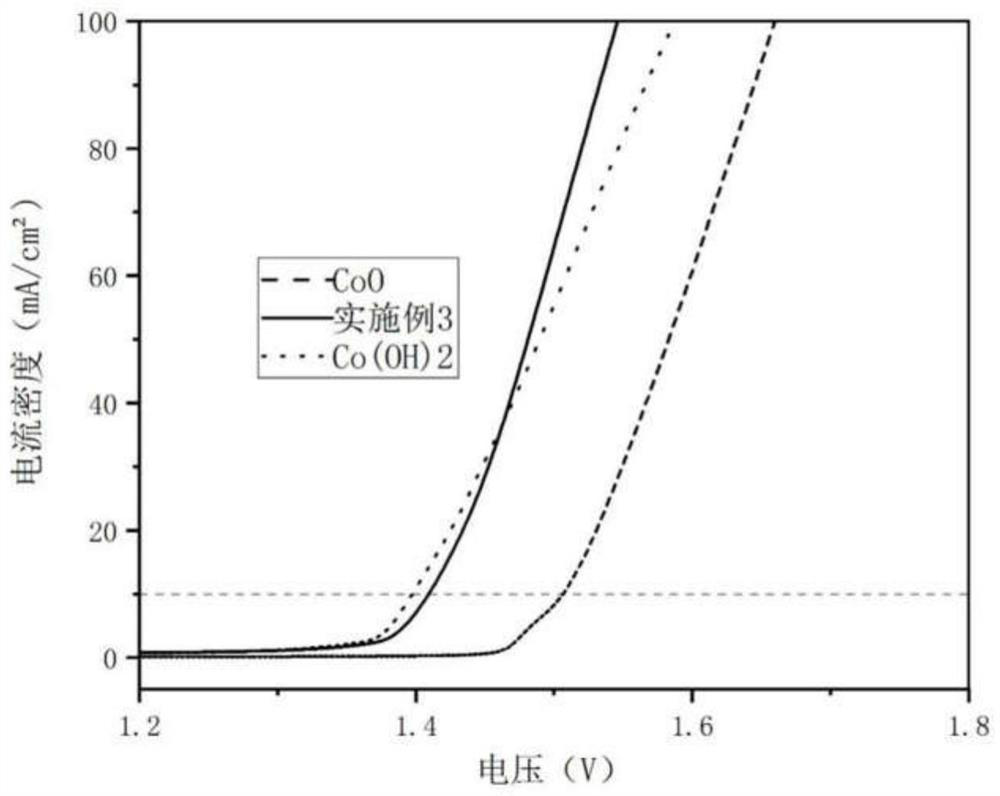

[0054] Depend on image 3 The LSV can operate at a current density of 10mAcm -2 , the oxygen evolution overpotential of the cobalt-based catalyst was 194mV. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com