Agricultural product packaging and stacking closed storage method in mechanical controlled atmosphere mode

A technology for agricultural products and machinery, applied in the field of packaging and stacking closed storage and maintenance of agricultural products, can solve the problems of suffocation of personnel, difficulty in stabilizing the effective concentration of pest control in sealed stacking, increasing the difficulty of mechanical regulation and energy consumption of equipment, etc., to avoid problems such as drain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

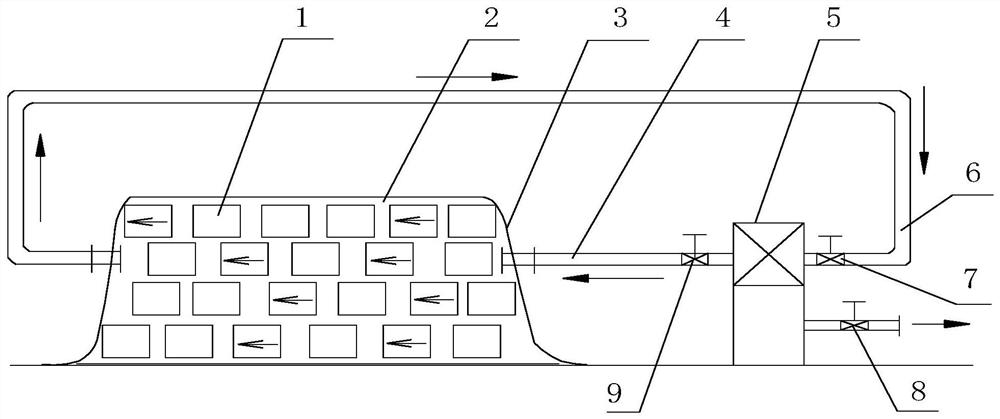

Embodiment 1

[0081] The agricultural product packaging and stacking airtight storage method under the mechanical atmosphere mode, the agricultural product (this embodiment refers specifically to wheat or tobacco leaves) after the wheat is harvested must complete a post-ripening process to achieve better eating quality, during which there will be vigorous breathing function, it will absorb oxygen and release carbon dioxide gas; after the tobacco leaves are planted, the initial roasting and the tobacco leaves after threshing and redrying will also have strong respiration, which will absorb oxygen and release a large amount of carbon dioxide gas. The natural alcoholization of tobacco leaves improves the quality of tobacco leaves; during the above-mentioned period, agricultural products wheat or tobacco leaves are packaged, transported, stacked and stored, and mechanical ventilation, humidity control, and nitrogen-filled atmosphere control of agricultural products are completed to prevent insect...

Embodiment 2

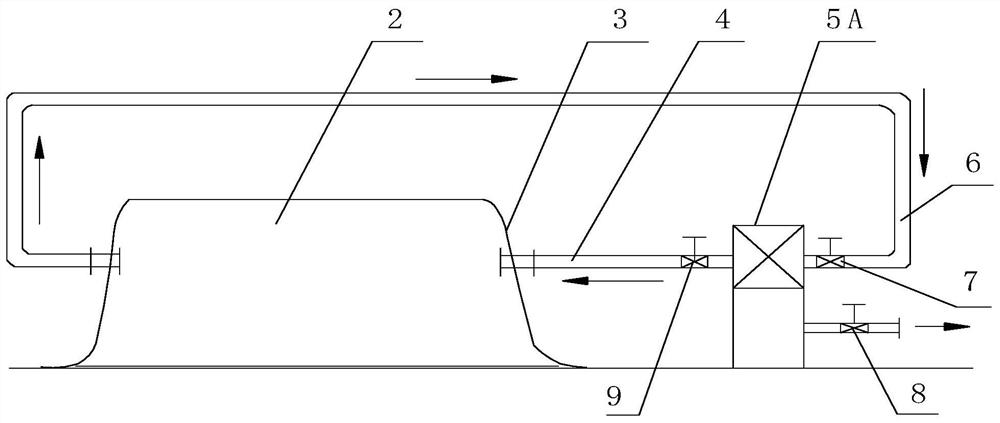

[0097] It is basically the same as in Example 1, except that the same non-polar molecular structure polypropylene plastic film is used to replace the polyethylene plastic film to make the packaging bag 1, and the plastic airtight tent 3 covered by the surface layer of the agricultural product stack and the inside of the agricultural product stack Between the packaging bags 1 used, a combination mode of "plastic airtight tent of nylon composite film on the surface + packaging bag of polypropylene plastic film inside" is used to construct a packaging bag that can satisfy agricultural product packaging, storage and mechanical regulation of its interior. Closed space 2; open the nitrogen generator to extract air from the closed space 2 and separate the nitrogen and oxygen in it, and discharge the separated and removed oxygen into the ambient atmosphere outside the plastic airtight tent 3, and the remaining The nitrogen cycle is fed back to the inside of the plastic airtight tent 3,...

Embodiment 3

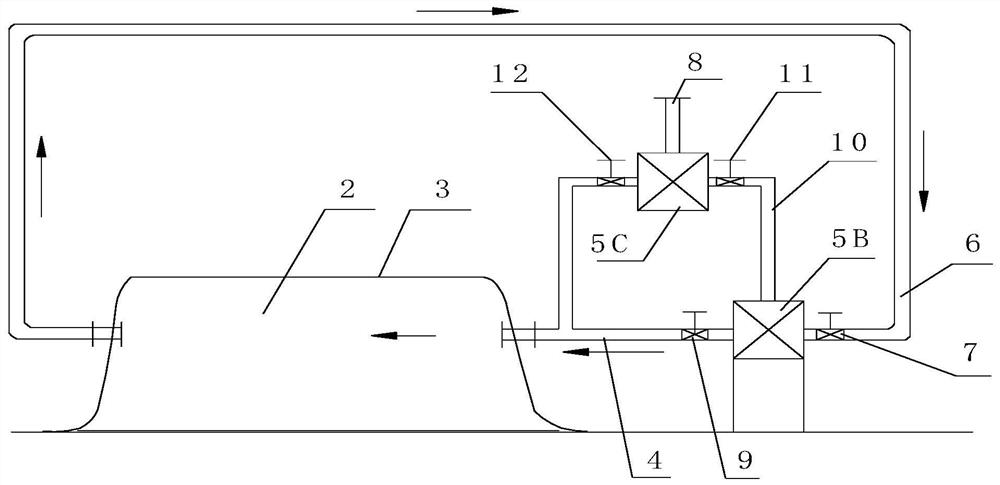

[0099] It is basically the same as Example 1.2, the difference is that: use polyvinyl chloride plastic film with polar molecular structure instead of nylon composite film material to make plastic airtight tent 3, plastic airtight tent (or claim: plastic airtight tent) 3 and packaging Between bags 1, use "plastic airtight tent 3 of surface layer polyvinyl chloride plastic film + inner polyethylene plastic film packaging bag 1" or "plastic airtight tent 3 of surface layer polyvinyl chloride plastic film + inner polypropylene plastic The combination mode of the film packaging bag 1" constructs a closed space 2 that can satisfy the packaging, storage and mechanical regulation of the interior of agricultural products, which can effectively block the escape of nitrogen and carbon dioxide in the plastic airtight tent, so that its concentration can be adjusted. Stably maintained in the airtight space 2 formed by the plastic airtight tent;

[0100] Turn on the nitrogen generator (nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com