Inorganic hollow vitrified microbead thermal insulation mortar and preparation method thereof

A technology of empty vitrified microbeads and thermal insulation mortar, which is applied in the field of building materials, can solve the problems of easy cracking and durability of plastering mortar, unsatisfactory thermal insulation and anti-freezing effect, and unsatisfactory anti-freezing performance, so as to avoid hollowing and cracking, Good operating feel and the effect of improving the efficiency of wiping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

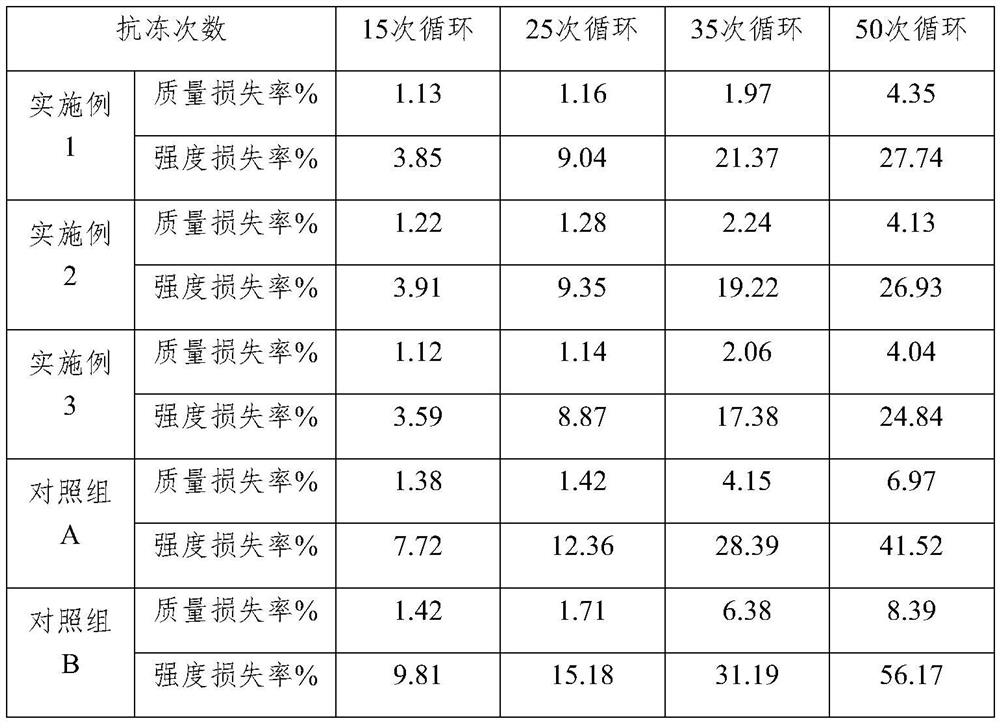

Examples

Embodiment 1

[0023] An inorganic hollow vitrified microbead insulation mortar, raw materials in parts by weight: 400 parts of cement, 50 parts of fly ash, 50 parts of ash calcium, 300 parts of hollow vitrified microbeads, 1 part of rubber powder, and 1 part of cellulose , 1 part of thickener.

[0024] The cement is composed of 95% by mass of Portland cement and 5% of magnesium oxychloride cement; preferably, the model of the Portland cement is No. 32.5.

[0025] The particle size of the fly ash is 40 mesh, the water content is 1%, the sulfur trioxide content is 0.5%, and the loss on ignition is 1.5%.

[0026] The particle size of the gray calcium is 500 mesh.

[0027] The particle size of the hollow vitrified microspheres is 50 mesh, and the bulk density is 20kg / m 3 , The thermal conductivity is 0.05W / m·k.

[0028] The particle size of the rubber powder is 380 μm, the bulk density is 515 kg / m3, the solid content is 99%, and the film-forming temperature is 1°C.

[0029] The cellulose is...

Embodiment 2

[0033] An inorganic hollow vitrified microbead insulation mortar, raw materials in parts by weight: 500 parts of cement, 150 parts of fly ash, 150 parts of ash calcium, 400 parts of hollow vitrified microbeads, 5 parts of rubber powder, and 5 parts of cellulose , 5 parts of thickener.

[0034] The cement is Portland cement; the model of the Portland cement is No. 42.5.

[0035] The particle size of the fly ash is 50 mesh, the water content is 5%, the sulfur trioxide content is 1%, and the loss on ignition is 3%.

[0036] The particle size of the gray calcium is 800 mesh.

[0037] The particle size of the hollow vitrified microspheres is 100 mesh, and the bulk density is 40kg / m 3 , The thermal conductivity is 0.1W / m·k.

[0038] The particle size of the rubber powder is 420 μm, the bulk density is 525 kg / m3, the solid content is 99%, and the film-forming temperature is 1°C.

[0039] The cellulose is methyl cellulose.

Embodiment 3

[0043] An inorganic hollow vitrified microbead insulation mortar, raw materials in parts by weight: 450 parts of cement, 100 parts of fly ash, 90 parts of ash calcium, 360 parts of hollow vitrified microbeads, 1.5 parts of rubber powder, and 1.5 parts of cellulose , 2.0 parts of thickener.

[0044] The cement is composed of 98% by mass of Portland cement and 2% of magnesium oxychloride cement; preferably, the model of the Portland cement is No. 42.5.

[0045] The particle size of the fly ash is 50 mesh, the water content is 3%, the sulfur trioxide content is 0.8%, and the loss on ignition is 2%.

[0046] The particle size of the gray calcium is 600 mesh.

[0047] The particle size of the hollow vitrified microspheres is 80 mesh, and the bulk density is 30kg / m 3 , The thermal conductivity is 0.08W / m·k.

[0048] The particle size of the rubber powder is 400 μm, the bulk density is 520 kg / m3, the solid content is 99%, and the film-forming temperature is 1°C.

[0049] The cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com