Preparation method and application of antiviral moisture-permeable coating

A toxic and moisture-permeable technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as lack of anti-virus effect and indirect infection of protective clothing, and achieve excellent anti-virus performance, Prevents the decline of antiviral properties and the effect of high water vapor transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

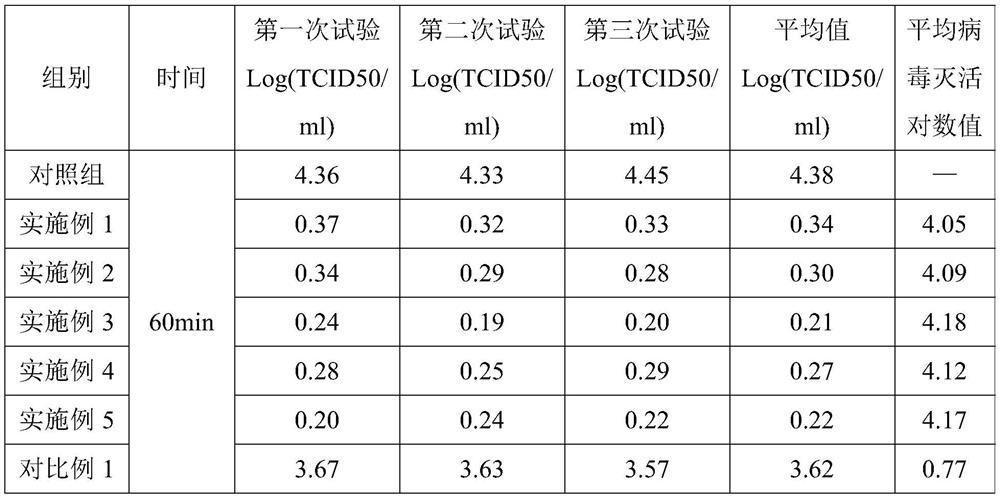

Examples

Embodiment 1

[0043] Under the protection of nitrogen, 10g polyethyleneimine (BASF lupasol WF, number average molecular weight: 25000), 10g bromobutane, and 10g potassium carbonate were added to ethanol, stirred and heated at reflux at 80°C for 8h. After cooling, the solid was removed by filtration, and the volatile matter was removed from the filtrate at 110° C. under nitrogen protection to obtain polyethyleneimine quaternary ammonium salt A.

[0044] Dissolve 5g of polyvinyl alcohol 1799 in 95ml of hot water, cool to room temperature 25°C, then add 10g of isocyanate, 1g of polyethyleneimine quaternary ammonium salt A and 1g of oxalic acid, stir evenly and vacuum defoam to obtain the anti-foaming agent of the present invention. Virus breathable paint. The antiviral moisture-permeable coating was coated on a PET non-woven fabric with a thickness of 30 um, and dried in an oven at 60° C. for 1 min to obtain the antiviral moisture-permeable film of the present invention.

Embodiment 2

[0046] Under the protection of nitrogen, 10g of polyethyleneimine (BASF lupasol WF, Germany, number average molecular weight: 25000), 10g of bromobutane, 10g of bromohexane, and 10g of potassium carbonate were added to ethanol, stirred and heated to reflux at 80°C for 8h. After cooling, the solid was removed by filtration, and under the protection of nitrogen, the filtrate was subjected to negative pressure removal of volatiles at 110° C. to obtain polyethyleneimine quaternary ammonium salt B.

[0047]Add 10g of polyurethane emulsion (Anhui Andahuatai, AH1618) into 90ml of water, cool to room temperature, then add 10g of isocyanate, 1g of polyethyleneimine quaternary ammonium salt and 1g of oxalic acid, stir evenly and vacuum defoam, to obtain the polyurethane of the present invention Anti-viral moisture-permeable coating. The antiviral moisture-permeable coating was coated on a PET non-woven fabric with a thickness of 30 um, and dried in an oven at 60° C. for 1 min to obtain ...

Embodiment 3

[0049] Under the protection of nitrogen, 10g of polyethyleneimine (BASF lupasol WF, number average molecular weight: 25000), 10g of bromobutane, 10g of bromooctane, and 10g of potassium carbonate were added to ethanol, stirred and heated to reflux at 80°C for 8h. After cooling, the solid was removed by filtration, and the volatile matter was removed from the filtrate under negative pressure at 110° C. under nitrogen protection to obtain polyethyleneimine quaternary ammonium salt C.

[0050] Disperse 5g of hydroxyethyl cellulose (Shandong Chuangyao, HEC-60000) in 95ml of water, and dissolve it completely with a small amount of ammonia water, then add 10g of isocyanate, 1g of polyethyleneimine quaternary ammonium salt and 1g of oxalic acid, stir well and vacuum remove Bubble, obtain antiviral moisture-permeable coating of the present invention. The antiviral moisture-permeable coating was coated on a PP non-woven fabric with a thickness of 20 um, and dried in an oven at 60° C. f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com