A bionic fishtail structure driven by pvc gel artificial muscle

An artificial muscle and gel technology, applied in the field of bionic robots, can solve the problems of easy breakdown, slow response, small driving force, etc., and achieve the effect of satisfying performance requirements and simple driving method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation process of PVC gel film 7 is as follows:

[0049] Use PVC particles with a degree of polymerization > 3600 (preferably PVC particles with a degree of polymerization of 4400), mix them with the plasticizer dibutyl adipate (DBA) at a mass ratio of 1: (1 to 14), and add after mixing The organic solvent tetrahydrofuran is diluted, and the mass ratio of the mixture to tetrahydrofuran is 1: (1-14). Finally, a PVC gel film with a thickness of 100-500 μm is prepared by casting a film.

[0050] The anode 8 adopts steel wire mesh or conductive mesh yarn, overlaps and aligns the multi-layer 300mm*300mm steel mesh flat sheets, clamps and fixes its edges on the CNC wire cutting machine, and processes the size through wire cutting. There is 5mm*5mm in the middle of one end Lug the positive electrode of the steel mesh. Clean the wire mesh electrode with deionized water and ethanol successively, remove residual chips and cutting fluid, and dry and store; it can ensure ...

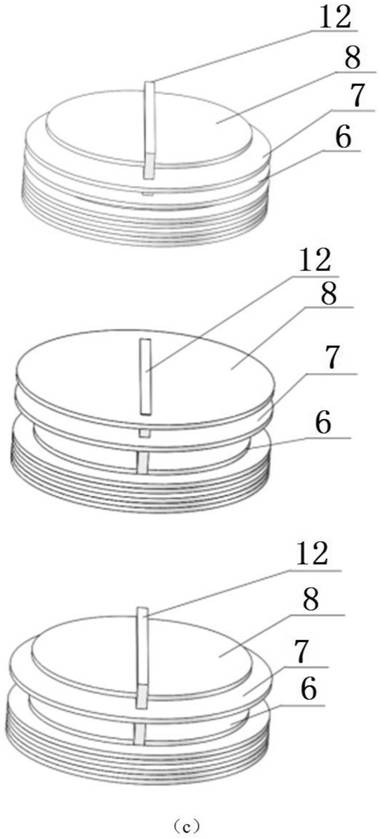

Embodiment 1

[0065] see image 3 , first make a PVC gel film, weigh PVC particles and plasticizer dibutyl oxalate (DBA) and mix them with a mass ratio of 1:4, then add tetrahydrofuran after mixing, the mass P ratio of the mixture mass and tetrahydrofuran 1:4, stir evenly, and prepare a 300 μm thick PVC gel film through the film building or glue homogenization process of the glue homogenizer;

[0066] The anode mesh electrode 8 uses 60-mesh stainless steel metal mesh, and the cathode plane electrode uses 0.02mm copper foil;

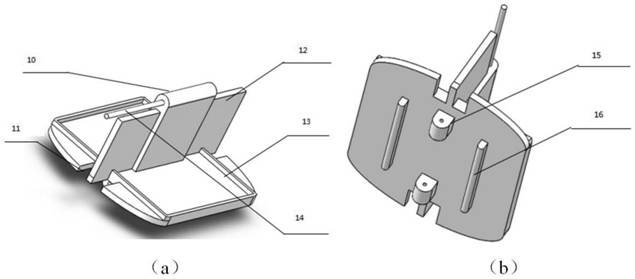

[0067] see image 3 , with the PVC gel film 7 as the core layer, the anode electrode 8, the PVC gel film 7 and the cathode electrode 6 are stacked in a sandwich structure to obtain the PVC gel drive unit 9;

[0068] Stack the single-layer PVC gel drive unit 9 to obtain the PVC gel drive module 3.

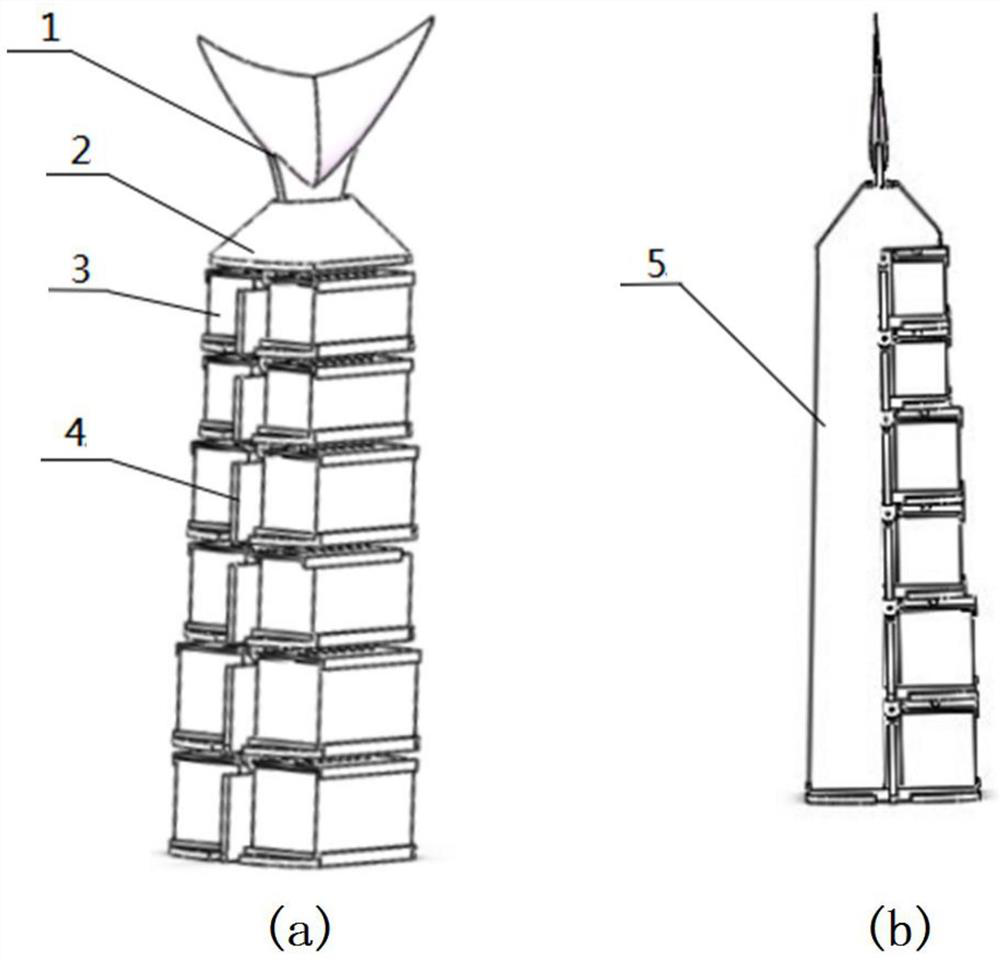

[0069] see figure 2 , according to the propulsion theory of the central fin or pair of fins, the optimum water striking angle should be 20 to 25 degrees, which is more ...

Embodiment 2

[0082] Please combine image 3 , first make a PVC gel film, weigh PVC particles and plasticizer dibutyl oxalate (DBA) and mix them with a mass ratio of 1:8, add tetrahydrofuran after mixing, the mass P ratio of the mixture quality and tetrahydrofuran 1:8, stir evenly, and prepare a 200 μm thick PVC gel film by building a film or a homogenizing process with a homogenizer;

[0083] The anode mesh electrode 1 uses 80-mesh stainless steel metal mesh, and the cathode plane electrode uses 0.04 copper foil;

[0084] combine image 3 , with the PVC gel film 7 as the core layer, the anode electrode 8, the PVC gel film 7 and the cathode electrode 6 are stacked in a sandwich structure to obtain the PVC gel driving unit 9; the single-layer PVC gel driving unit 9 is carried out Stack to get PVC gel drive module 3.

[0085] see figure 2 , according to the MPF propulsion theory, the optimum water striking angle should be 20-25 degrees, which is more appropriate. The bionic fishtail is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com