Underwater repairing material based on seawater and coral sand and preparation method thereof

A technology for repairing materials and coral sand, applied in the field of building materials, can solve problems such as scarcity of sand and gravel resources, and achieve the effects of improving cohesion and fluidity, limiting deformation of mortar, and improving compressive strength and bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

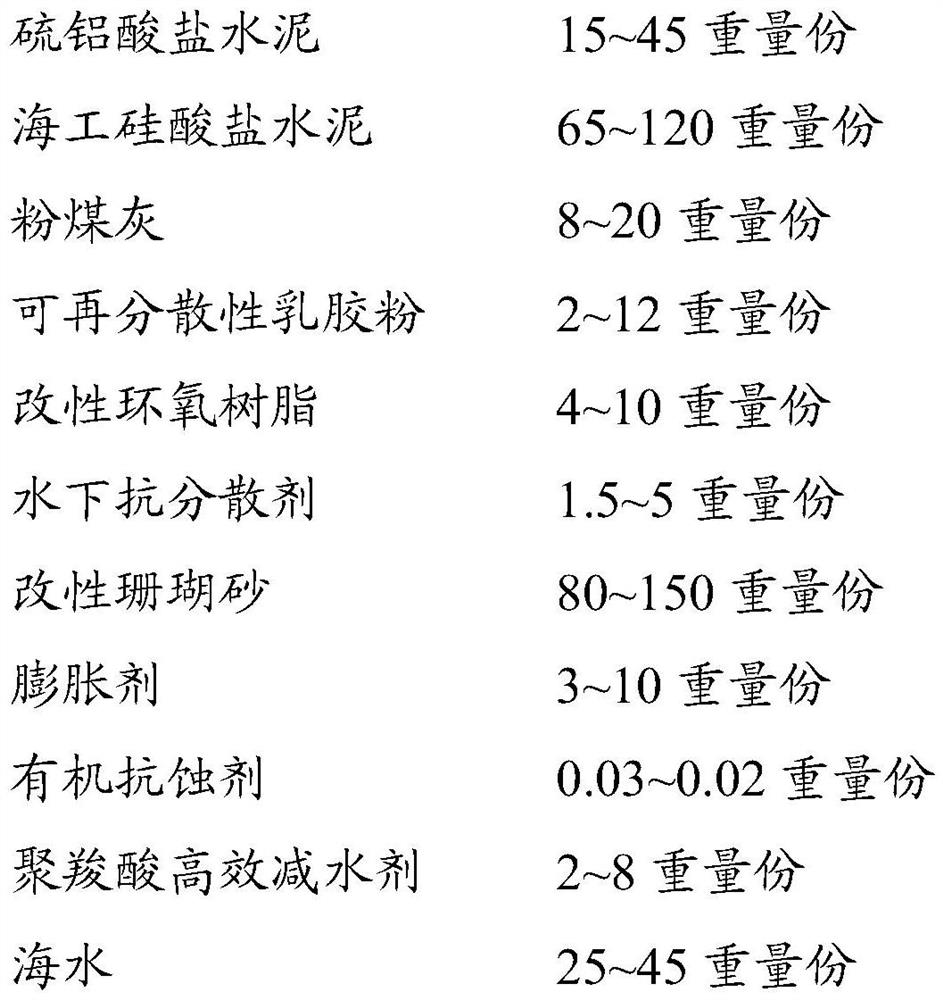

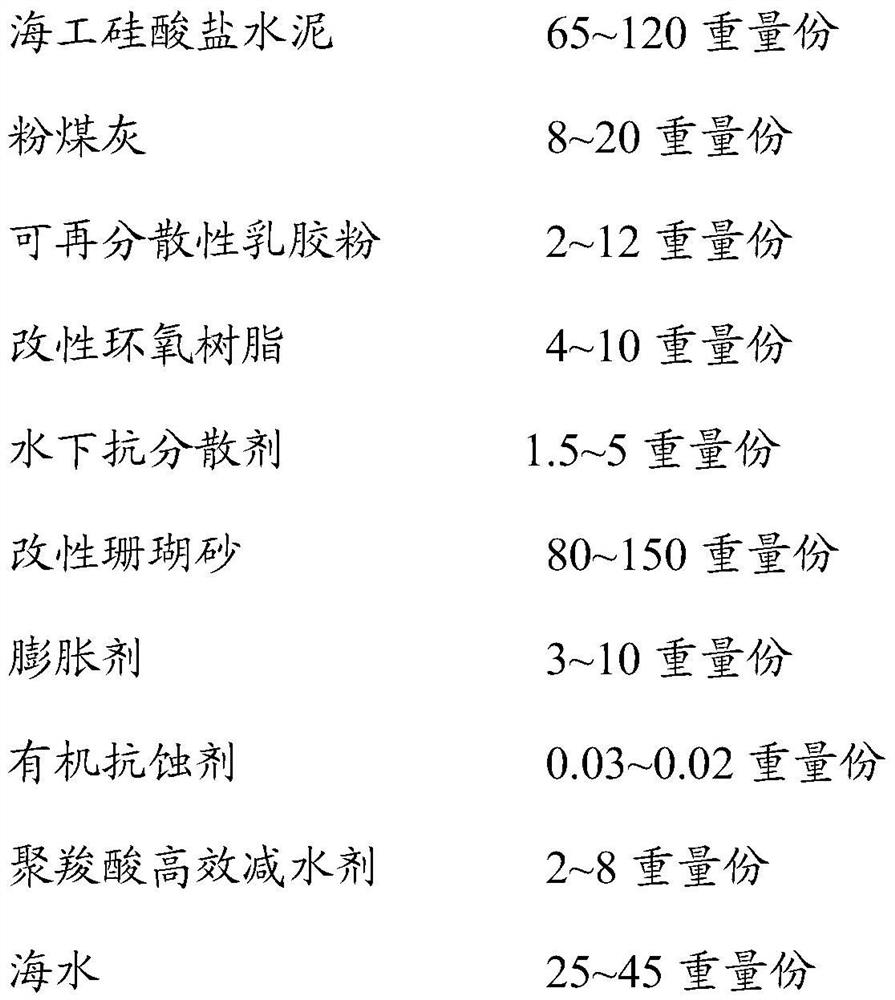

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of modified coral sand:

[0040] Crush the coral sand to an average particle size of 0.35-0.25 mm, spread it evenly and send it to the spray area; atomize monosilane into negatively charged tiny particles, and use a compressed air pressure of 0.7 MPa and 150 kV electric field for atomization. Atomization humidity is 8g / mm 2 Atomized for 15 minutes under certain conditions to obtain coral sand coated with a hydrophobic coating, that is, modified coral sand. The treatment process is similar to the glaze spraying process of ceramic preparation. Monosilane is a permeable coating, which can not only play a "coating role" to form an organic film on the surface of coral sand, inhibit the removal of erosive ions in undiluted coral sand, but also The alkaline substances in the mortar act to form a hydrophobic film, which reduces the diffusion coefficient of chloride ions in the structure.

[0041] 2. Preparation of redispersible latex powder:

[0042] Add polyp...

Embodiment 2

[0054] 1. Preparation of modified coral sand:

[0055] Crush the coral sand to an average particle size of 0.35-0.25mm, spread it evenly and send it to the spray area; atomize the monosilane into negatively charged tiny particles, in a 160 kV electric field, the compressed air pressure for atomization is 0.6MPa, Atomization humidity is 9g / mm 2 Atomized for 20 minutes under certain conditions to obtain coral sand coated with a hydrophobic coating, that is, modified coral sand.

[0056] 2. Preparation of redispersible latex powder:

[0057] Add polypropylene acetate (weight-average molecular weight: 15,000), polyvinyl alcohol (weight-average molecular weight: 160,000) and methyl methacrylate into the reactor at a weight ratio of 72:16:1 to obtain mixed solution A; Polyvinyl alcohol (corresponding to 1.2wt% of mixed solution A) aqueous solution into the reactor, and turn on the stirrer to stir for 25min, then raise the temperature to 90 ° C, dropwise add azobisisobutyronitrile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com