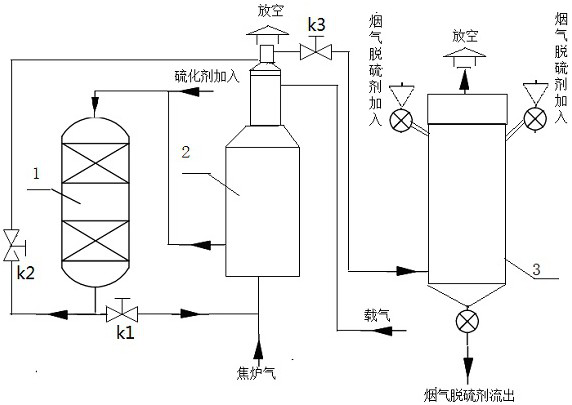

A gas hydrogenation catalyst sulfidation and sulfidation waste gas treatment and discharge process

A hydrogenation catalyst and exhaust gas treatment technology, applied in the field of coal chemical industry, can solve the problem of being reduced before sulfidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Sulfurization of 50 m in a coke oven gas to synthetic natural gas plant in Xinjiang 3 Primary hydrogenation. The volume ratio of the catalyst to the external presulfurized catalyst is 8:7, respectively 26.7 m 3 and 23.3 m 3 , the total number of layers in the room is 15 layers, and each layer is filled with 3.3 m 3 . The external presulfided catalyst is prepared by dry method, and the degree of sulfidation is 70%. Vulcanizing agent is CS 2 , prepare 2.02 tons. Replace flue gas desulfurizer 7.31 m 3 , The sulfur capacity of the flue gas desulfurizer is 31%. SO in exhaust flue gas 2 less than 30mg / m 3 , no white smoke is generated. The specific vulcanization process is as follows:

[0042] (1) Use a heating furnace to heat nitrogen to raise the temperature of the catalyst at a heating rate of 20°C / h, and control the temperature of each point of the bed to not exceed 200°C , Control the pressure at 0.1MPa, raise the temperature for 9 hours to 200°C in the upper...

Embodiment 2

[0048] Sulfurization of 18.7 m in a coke oven gas to methanol plant in Shaanxi 3 Prehydrogenation. The volume ratio of the catalyst to the external presulfurized catalyst is 3:2, respectively 11.2 m 3 and 7.5 m 3 , the total number of layers in the room is 5 layers, and each layer is filled with 3.7m 3 . The presulfurized catalyst outside the device is prepared by wet method, and the degree of sulfidation is 40%. The vulcanizing agent is dimethyl disulfide, and 0.94 tons are prepared. Replace flue gas desulfurizer 2.85 m 3 , Flue gas desulfurization agent sulfur capacity 30%. SO in exhaust flue gas 2 less than 30mg / m 3, no white smoke is generated. The specific vulcanization process is as follows:

[0049] (1) Use a heating furnace to heat nitrogen to raise the temperature of the catalyst at a heating rate of 30°C / h, and control the temperature of each point of the bed to not exceed 200°C , The pressure is controlled at 0.2MPa; after 6 hours, the temperature of the ...

Embodiment 3

[0055] Sulfurization of 29 m in a coke oven gas to synthetic natural gas plant in Hebei 3 Primary hydrogenation. The loading volume ratio of the catalyst to the external presulfurized catalyst is 5:4, respectively 16.1 m 3 and 12.9 m 3 , the total number of layers in the room is 9 layers, and each layer is filled with 3.2m 3 . The external presulfided catalyst is prepared by dry method, and the degree of sulfidation is 55%. Vulcanizing agent is CS 2 , prepare 1.31 tons. Replace flue gas desulfurizer 4.74 m 3 , The sulfur capacity of the flue gas desulfurizer is 32%. SO in exhaust flue gas 2 less than 30mg / m 3 , no white smoke is generated. The specific vulcanization process is as follows:

[0056] (1) Use a heating furnace to heat nitrogen to raise the temperature of the catalyst at a heating rate of 25°C / h, and control the temperature of each point of the bed to not exceed 200°C , The pressure is controlled at 0.15MPa; after 7.2 hours, the temperature of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com