Plasma-assisted method for preparing perovskite type methane combustion catalyst

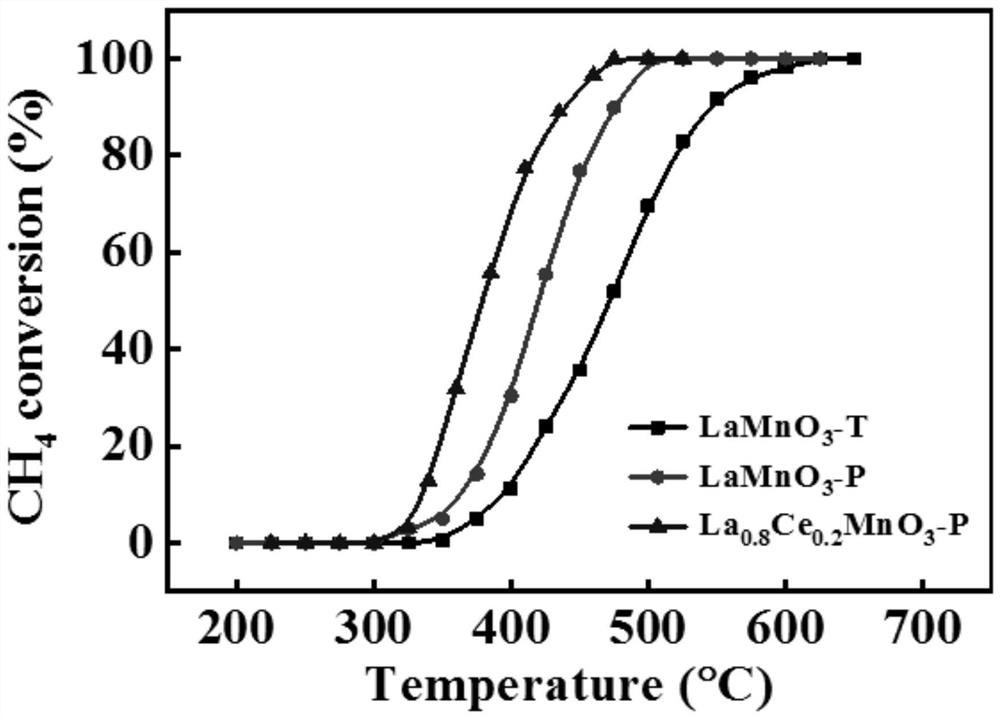

A plasma and methane combustion technology, applied in combustion methods, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of small specific surface area of catalysts, affecting the catalytic efficiency of catalysts, and few defect sites, etc. The effect of low grain size and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

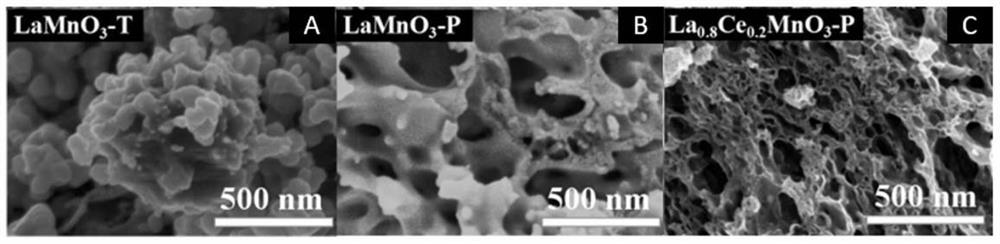

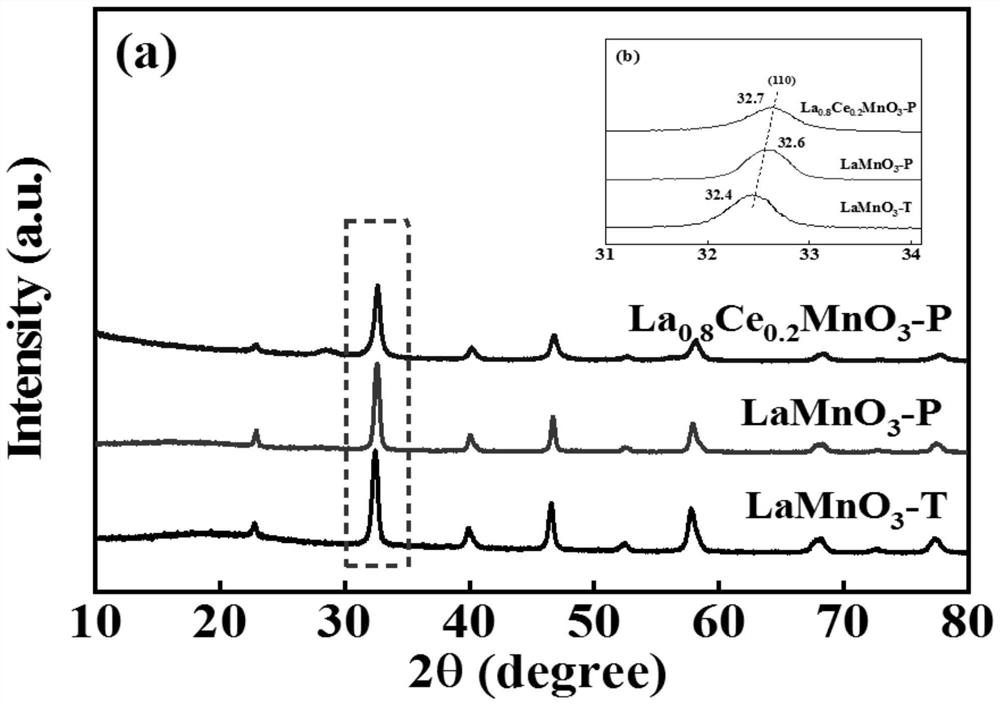

[0034] Take deionized water as solvent, weigh appropriate amount of lanthanum nitrate and manganese nitrate according to the molar ratio of lanthanum ion and manganese ion as 1:1, and prepare a mixed and uniform metal salt solution with a concentration of 2mol / L; use citric acid as complex agent, according to the molar ratio of metal ions (lanthanum ions and manganese ions) to citric acid is 1:1.5, citric acid is added to the aqueous solution of lanthanum nitrate and manganese nitrate, and stirred evenly at room temperature to form a mixed solution containing metal complexes. Put the mixed solution in an oil bath, heat and stir at 80°C and evaporate into a gel, that is, a wet gel. The wet gel was put into an oven and dried at 110°C to obtain a dry gel. The dry gel was ground into a powder, placed in a muffle furnace, and pretreated at 300°C for 4 hours to obtain a precursor.

[0035] Put the precursor in the glow discharge plasma equipment, pass through oxygen, discharge power...

Embodiment 2

[0040] Use deionized water as solvent, weigh appropriate amount of lanthanum nitrate, cerium nitrate and manganese nitrate according to the molar ratio of lanthanum ion, cerium ion and manganese ion as 4:1:5, and make a mixed uniform metal nitrate with a concentration of 2mol / L Salt solution; using citric acid as a complexing agent, according to the molar ratio of metal ions and citric acid as 1:1.5, adding citric acid to the aqueous solution of lanthanum nitrate, cerium nitrate and manganese nitrate, stirring at room temperature to form a metal-containing complex mixed solution of substances. Put the mixed solution in an oil bath, heat and stir at 70°C and evaporate into a gel, that is, a wet gel. The wet gel was put into an oven and dried at 100°C to obtain a dry gel. The dry gel was ground into a powder, placed in a muffle furnace, and pretreated at 300°C for 3 hours to obtain a precursor.

[0041] The precursor was placed in a glow discharge plasma device, fed with oxygen...

Embodiment 3

[0050] With deionized water as solvent, take appropriate amount of lanthanum chloride and cobalt chloride according to the molar ratio of lanthanum ion and cobalt ion as 1:1, and prepare a mixed and uniform metal salt solution with a concentration of 3mol / L; use citric acid as Complexing agent, according to the mol ratio of metal ion and citric acid is 1:1.4, citric acid is added in the aqueous solution of lanthanum chloride and cobalt chloride, stirs at normal temperature, forms the mixed solution containing metal complex; Put mixed solution In an oil bath at 70°C, heat and stir to evaporate into a gel, that is, a wet gel. The wet gel was put into an oven and dried at 100°C to obtain a dry gel. The dry gel was ground into a powder, placed in a muffle furnace, and pretreated at 300°C for 3 hours to obtain a precursor.

[0051] The precursor was placed in a glow discharge plasma device, fed with oxygen, the discharge power was 100kW, and treated in an oxygen atmosphere at 500°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com