Preparation method of carbon material for supercapacitor, carbon material and application of carbon material

A technology for supercapacitors and carbon materials, which is applied in chemical instruments and methods, hybrid capacitor electrodes, inorganic chemistry, etc., can solve the problems of hindering the performance of supercapacitors, the ash content of carbon materials is not low enough, and the specific surface area is not high enough to improve activation and pore formation ability, increase the probability of reaction participation and degree of reaction, and activate the effect of surface structure characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

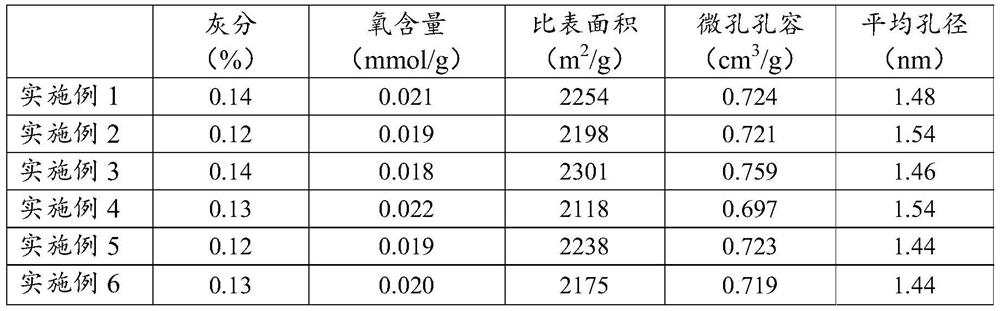

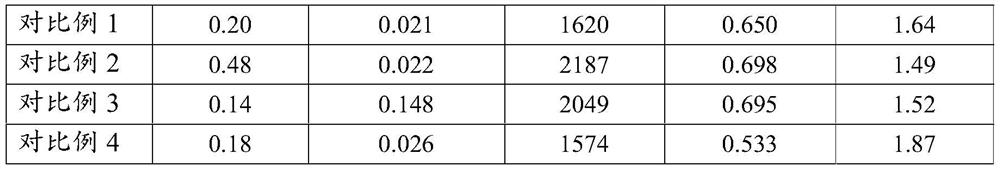

Examples

preparation example Construction

[0038] One embodiment of the present invention provides a method for preparing carbon materials for supercapacitors, comprising the following steps:

[0039] Step 102, uniformly mixing a certain amount of pretreated carbon-containing precursor with a certain amount of co-activator, and performing high-temperature activation treatment;

[0040] Step 104, mixing the first product obtained after the high-temperature activation treatment with a certain amount of mixed acid solution, heating and stirring, suction filtering, washing, drying after the reaction, and setting aside;

[0041] Step 106, reacting the second product obtained in step 104 with a certain amount of mixed gas of nitrogen and hydrogen at high temperature.

[0042] As a preferred implementation manner, in step 102, the pretreatment includes: grinding a certain amount of carbon-containing precursor into fine powder.

[0043] As a preferred embodiment, in step 102, the carbon-containing precursor is a mixture of pe...

Embodiment 1

[0060] The present embodiment provides a kind of preparation method of supercapacitor carbon material, comprises the following steps:

[0061] (1) 100g petroleum coke and 60g coal tar pitch particles are ground into 300 mesh fine powder;

[0062] (2) Mix 150g of the fine powder obtained in step (1) with 450g of sodium hydroxide evenly at a stirring speed of 400r / min, then place it on a flat die roller compactor under a pressure of 10MPa for 2h, and then squeeze it under a pressure of 35MPa into a 1mm cylindrical shape to obtain a columnar precursor;

[0063] (3) The columnar precursor obtained in step (2) was raised from room temperature to 200°C in a tube furnace, pre-oxidized by passing 120L / h air for 6h, and naturally cooled to room temperature to obtain a pre-oxidized precursor;

[0064] (4) The pre-oxidized precursor obtained in step (3) was activated in a high-temperature tube furnace from room temperature to 800°C for 6 hours at a constant temperature, and then cooled ...

Embodiment 2

[0071] The present embodiment provides a kind of preparation method of supercapacitor carbon material, comprises the following steps:

[0072] (1) 120g petroleum coke and 80g coal tar pitch particles are ground into 250 mesh fine powder;

[0073] (2) Mix the fine powder obtained by 200g of step (1) with 1000g of potassium carbonate at a stirring speed of 400r / min, then leave it on a flat die roller compactor for 3h under a pressure of 12MPa, and then extrude under a pressure of 30MPa to form 3mm cylindrical, to obtain a columnar precursor;

[0074] (3) Raise the columnar precursor obtained in step (2) from room temperature to 300°C in a tube furnace, pass 85L / h air into it for pre-oxidation for 4.5h, and naturally cool down to room temperature to obtain a pre-oxidized precursor;

[0075] (4) The pre-oxidized precursor obtained in step (3) was activated in a high-temperature tube furnace from room temperature to 800°C for 4.5 hours at a constant temperature, and then cooled do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com