Preparation method of ultra-fine wollastonite with high length-diameter ratio

A high aspect ratio, ultra-fine technology, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problems of weakened reinforcement effect, damage of fiber structure, limited product fineness, etc., to improve compatibility, The effect of improving dispersibility and slowing down the tendency of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

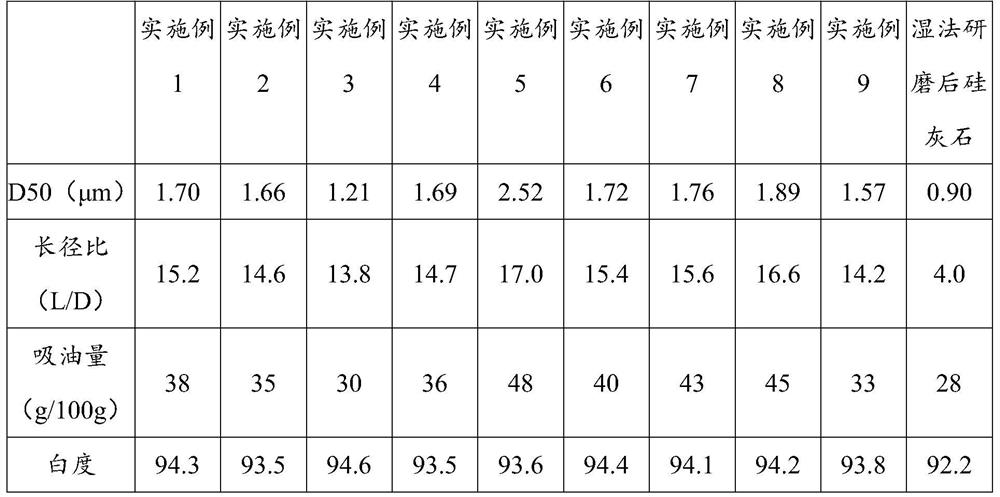

Examples

preparation example Construction

[0031] The invention provides a method for preparing ultrafine wollastonite with a high aspect ratio, comprising the following steps:

[0032] (1) Mix the ultrafine wollastonite slurry and the surfactant to obtain the first mixed slurry; the average particle diameter of the ultrafine wollastonite in the ultrafine wollastonite slurry is 0.8 to 1.0 μm, and the long diameter The ratio is 3 to 5;

[0033] (2) mixing water glass, tetraethyl orthosilicate and water to obtain a silicon pre-hydrolyzed solution; hydrolyzing the silicon pre-hydrolyzed solution under acidic conditions to obtain a silicon hydrolyzed solution;

[0034] (3) adding the silicon hydrolyzate and the calcium hydroxide suspension side-by-side to the first mixed slurry for liquid phase deposition reaction to obtain a second mixed slurry;

[0035] (4) After the second mixed slurry is subjected to a hydrothermal reaction, the hydrothermal reaction product is mixed with a coupling agent to obtain the ultrafine wolla...

Embodiment 1

[0053] Select the wollastonite concentrate with a calcium silicate content ≥ 96wt%, and after preliminary dry grinding and iron removal, the ultrafine wollastonite slurry is obtained by wet grinding in a vertical stirring mill. The particle size is 0.9μm, and the aspect ratio is 4;

[0054]Dilute the ultrafine wollastonite slurry to 30wt%, add a surfactant accounting for 1.0wt% of the slurry, surfactant DTAC: F127=6:1 (molar ratio), stir and disperse at a stirring speed of 300rpm for 10min, wait use;

[0055] Prepare 25wt% (as SiO 2 Calculate) silicon pre-hydrolyzed solution, wherein the molar ratio of water glass (modulus 2.6) to ethyl orthosilicate is 1:2, at a temperature of 60°C and a pH value of 4.5 (by adding 1 mol / L acetic acid dropwise) Regulated) under the condition of hydrolysis 30min, obtains silicon hydrolyzate;

[0056] Adopt co-current method, by peristaltic pump, newly synthesized 60wt% calcium hydroxide suspension and silicon hydrolyzate are added dropwise r...

Embodiment 2

[0058] Select wollastonite concentrate with calcium silicate content ≥ 96wt%, and after preliminary dry grinding and iron removal, ultrafine wollastonite slurry is obtained by wet grinding in a vertical stirring mill, and the ultrafine wollastonite slurry is The average particle size is 0.9μm, and the aspect ratio is 4;

[0059] Dilute the ultrafine wollastonite slurry to 30wt%, add surfactants accounting for 1.5wt% of the slurry, surfactant DTAC: F127=6:1 (molar ratio), stir and disperse at a stirring speed of 300rpm for 10min, wait use;

[0060] Prepare 25wt% (as SiO 2 Calculated) silicon pre-hydrolyzate, wherein the molar ratio of water glass (modulus 2.6) to ethyl orthosilicate is 1:3, at a temperature of 60°C and a pH value of 4.5 (by adding 1 mol / L acetic acid dropwise) Regulated) under the condition of hydrolysis 30min, obtains silicon hydrolyzate;

[0061] Adopt co-current method, by peristaltic pump, newly synthesized 60wt% calcium hydroxide suspension and silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com