Chitinase fused with carbohydrate binding module, preparation method for chitinase and application of chitinase

A carbohydrate and chitinase technology, applied in the field of bioengineering, to achieve the effect of rich distribution, growth support and easy digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Determination of various components of shrimp shell waste

[0057] Shrimp shell waste was purchased from Zhanjiang Guolian Aquatic Products Development Co., Ltd., crushed through a 50-mesh sieve to obtain shrimp shell waste powder, and stored at 4 °C for future use. The methods for determining protein, ash, chitin and moisture in shrimp shell waste are as follows:

[0058] (1) Protein: Because chitin contains nitrogen, in order to eliminate interference, the shrimp shell powder was first treated with 1M NaOH solution at 40°C for 3 hours, and the protein concentration of the supernatant was determined by the Kjeldahl method (GB 50095-2010). The protein content in the shrimp shell was measured to be 48.84%;

[0059] (2) Ash content: using the "First Method Determination of Total Ash Content in Food" in the National Food Safety Standard (GB5009.4-2016), the measured ash content in shrimp shells is 20.75%;

[0060] (3) Chitin: firstly treat the shrimp shell ...

Embodiment 2

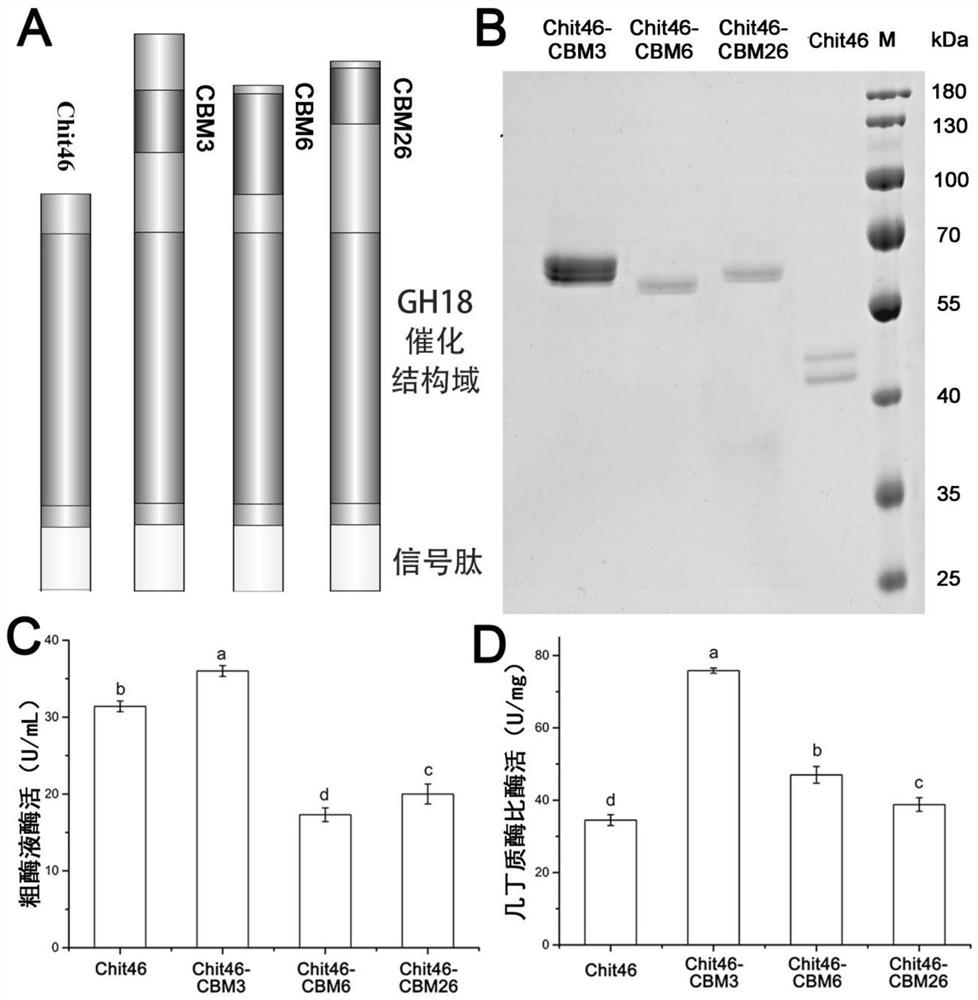

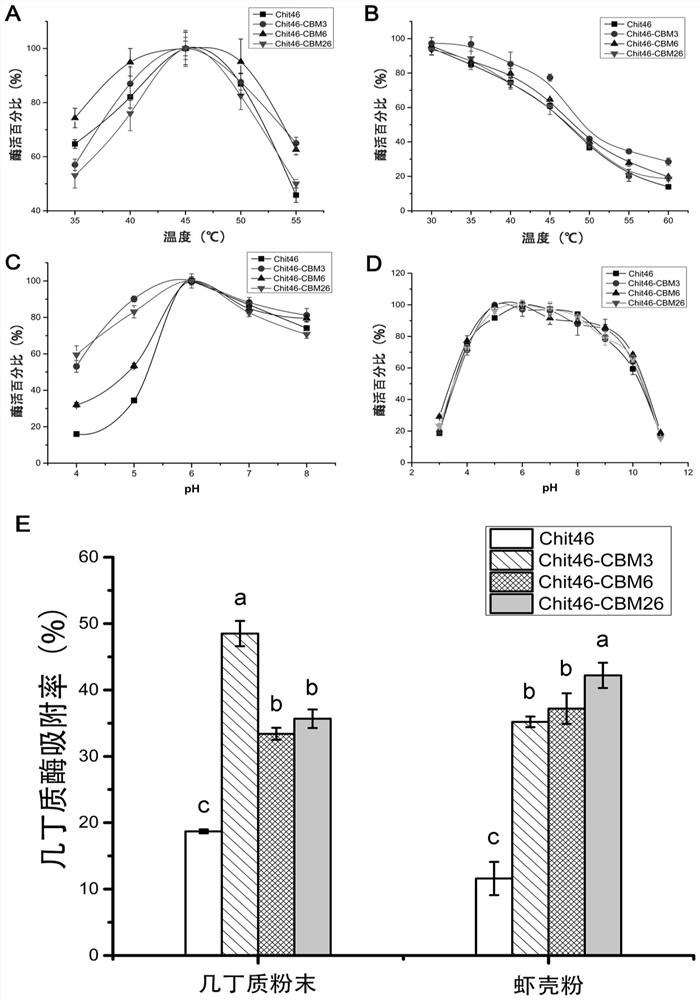

[0063] Example 2: Fusion of CBM with chitinase Chit46

[0064] The primer F1(5'-CTGC GAATTC AGCCCCCTGGCCACAG-3') and R1

[0065] (5'-ACTT ACGCGT AACT GGGCCC GTTCAGACCGTTCCTGATGTT-3') (the underlined sequences represent the EcoRI restriction site, the MluI restriction site and the ApaI restriction site respectively), and the Chit46-C fragment was obtained by PCR (the amino acid and nucleotide sequences of Chit46 are respectively as in China SEQ ID NO.1 and SEQ ID NO.2 in the patent application CN201910064040.5); using the cDNA of Bacillus subtilis 168 strain as a template, the primer F3 (5'-AACT GGGCCC CAGGAATCATCCTCAGCT-3') and R3(5'-ACTT ACGCGT ATTTGGTTCTGTTCCCCCA-3') (the underlined sequences represent the ApaI restriction site and the MluI restriction site respectively), and the CBM3 with the connecting peptide was obtained by PCR method (derived from the sequence Genbank: CAA82317); with the Bacillus subtilis 168 strain cDNA as template, design primer F6

[0066...

Embodiment 3

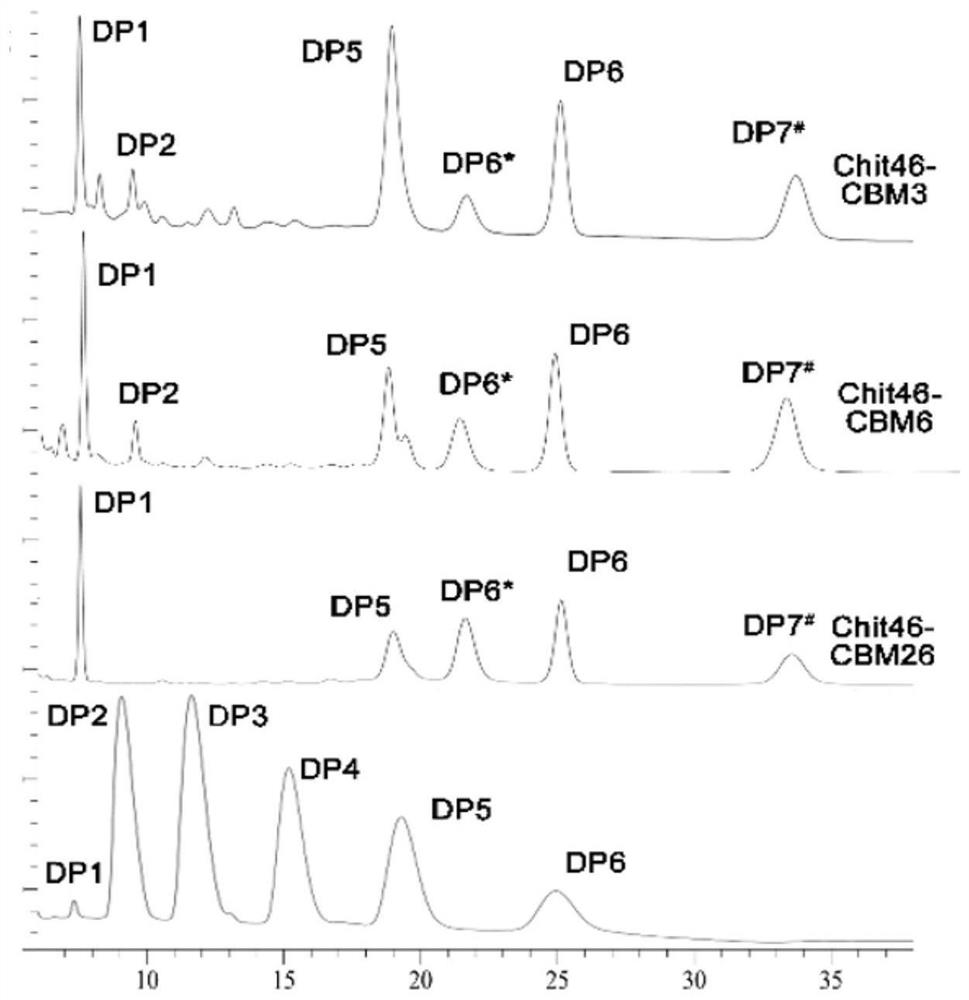

[0107] Example 3 Chitinase hydrolysis of shrimp shell powder and hydrolyzate analysis

[0108] (1) In order to compare the efficiency of different fusion chitinases in hydrolyzing shrimp shell waste, 100 U fusion chitinases Chit46-CBM3, Chit46-CBM6 and Chit46-CBM26 were mixed with 1 g shrimp shell powder at 40 °C, and then Add 50mM pH 6.0 sodium phosphate buffer until the total volume of the mixture is 10mL. After hydrolysis for 12 hours, centrifuge at 5000rpm for 10 minutes to obtain chitin hydrolyzate and shrimp shell residue. Chitinase is used as a control.

[0109] Add the same volume of 95% (v / v) ethanol to the chitin hydrolyzate of shrimp shells and centrifuge at 12000rpm for 1min, the precipitate is protein, and the remaining solution contains chitooligosaccharide (hereinafter referred to as: chitooligosaccharide sugar solution). The precipitated protein was redissolved in the same volume of sterile water as the chitin hydrolyzate of shrimp shell, and the protein conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com