Functionalized titanium dioxide/chlorella nano composite material based on graphene quantum dots and preparation method and application thereof

A technology of graphene quantum dots and composite materials, which is applied in the field of gas sensors, can solve the problems of poor gas sensitivity and achieve the effects of rapid response, high sensitivity and strong nano-effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

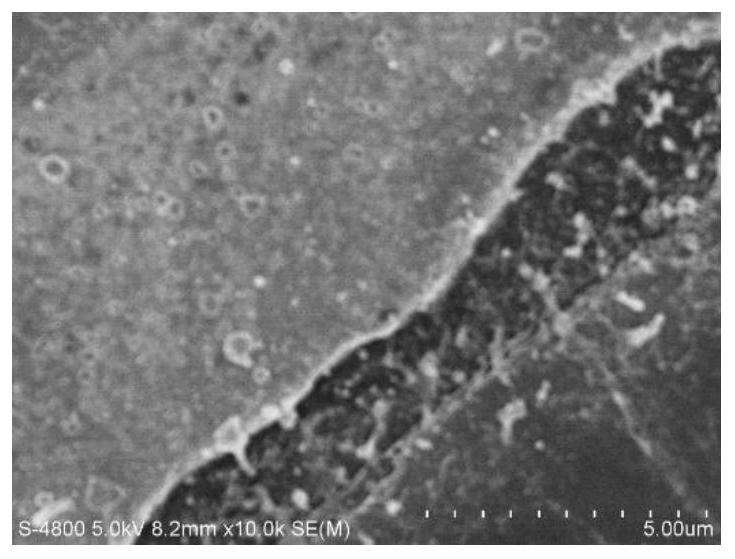

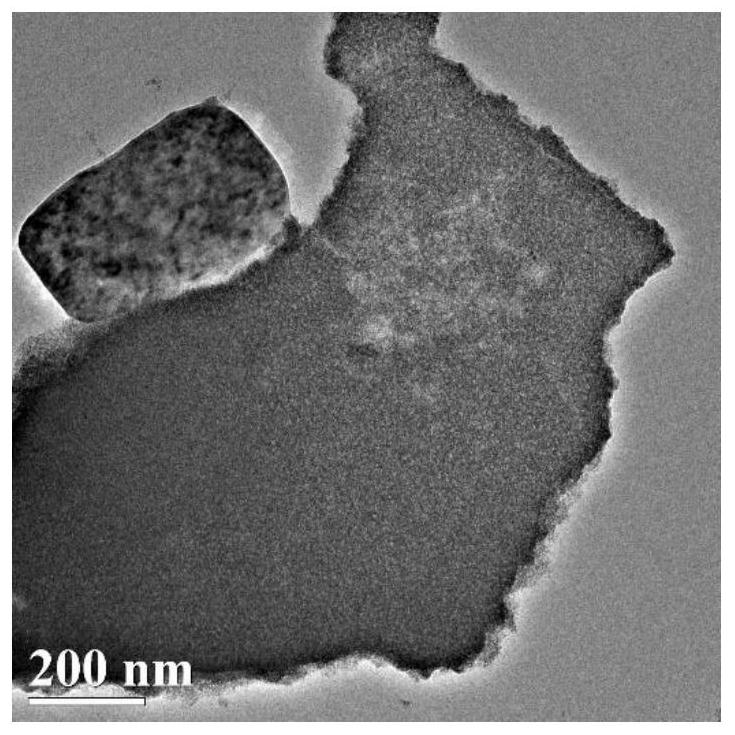

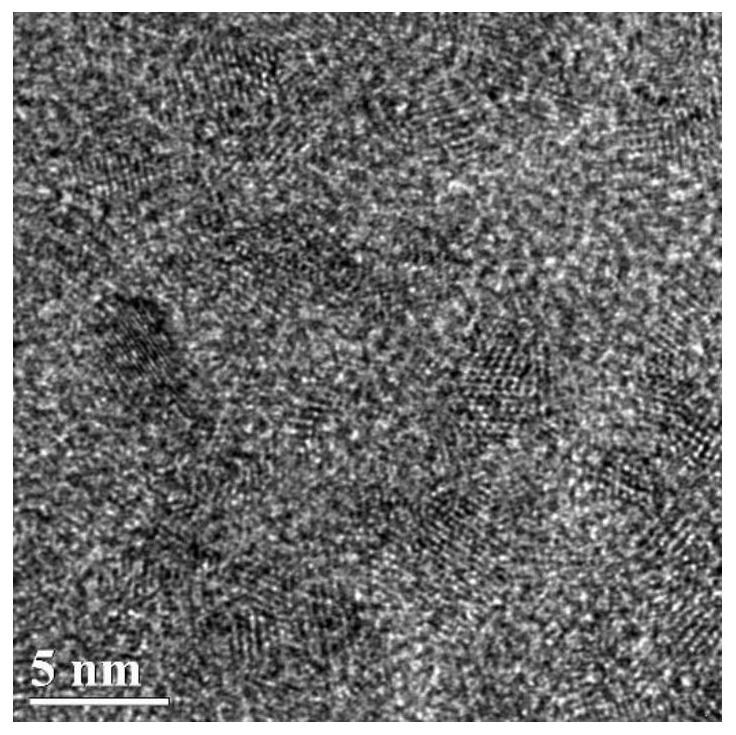

Image

Examples

Embodiment 1

[0063] The present invention is used for the composite film material of gas sensor, and preparation method is as follows:

[0064] Step 1: Carbonization of Chlorella:

[0065] Put the ceramic boat filled with chlorella into the tube furnace, first vacuumize, keep it for 8 minutes (5~10 minutes are acceptable), and then pass through the protective gas (for example, nitrogen atmosphere), and keep the gas flow rate at 100SCCM ( 50-200 SCCM is acceptable), followed by high-temperature roasting at 800°C (700-900°C is acceptable) for 3 hours (1-5 hours are acceptable) to prepare Carbonized Chlorella.

[0066] Step 2: Preparation of gold nanoparticles

[0067] First, add 3.0×10 to the beaker -2 mol / L (the concentration range is 5×10 -3 ~5×10 -2 mol / L is acceptable, preferably 1.2×10 -2 ~5×10 -2 mol / L) of chloroauric acid solution 10mL, 6×10 -4 mol / L (the concentration range is 1×10 -4 ~1×10 -3 mol / L is acceptable, preferably 5×10 -4 ~8×10 -4 mol / L) PVP solution 5mL and dei...

Embodiment 2

[0083] Preparation of composite materials

[0084] Add 3 g of tetrabutyl titanate and 100 mg of carboxylated graphene quantum dots to 10 ml of propanol and stir magnetically at room temperature for 36 hours, then ultrasonically disperse for 15 minutes, then add 6 ml of gold nanoparticles in propanol (concentration of 4 mg / ml) (the gold nanoparticles were prepared by the method in Example 1) was added to the above mixture, and then ultrasonically dispersed for 15 minutes to uniformly prepare a mixed solution. The mixed solution was evaporated by bubbling, and when the solution was reduced to 6 ml, 60 mg of Chlorella carboniferous (prepared by the method in Example 1) was added. After spin-coating, dry at 60-80°C for 2 hours, repeat the coating 4 times and dry. Put the coated device into an airtight container, adjust the humidity inside the container between 75%~85% and the temperature at 120°C~130°C, and take out the device after 48 hours of treatment. Oxygen plasma treatmen...

Embodiment 3

[0091] Preparation of composite materials

[0092] Add 1 gram of titanium tetrachloride and 60 mg of hydroxylated graphene quantum dots to 5 ml of isopropanol and stir magnetically at room temperature for 24 hours, then ultrasonically disperse for 10 minutes, then add 2 ml of gold nanoparticle isopropanol solution (concentration: 5 mg / ml) (the gold nanoparticles were prepared by the method in Example 1) was added to the above mixture, and then ultrasonically dispersed for 10 minutes to obtain a uniform mixture. The mixed solution was evaporated by bubbling, and when the solution was reduced to 3 ml, 30 mg of Chlorella carboniferous (prepared by the method in Example 1) was added. After spin-coating, dry at 60-80°C for 1.5 hours, repeat the coating 4 times and dry. Put the coated device into an airtight container, adjust the internal humidity of the container between 75%~85% and the temperature at 120°C~130°C, and take out the device after 36 hours of treatment. Oxygen plasma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com