Preparation method of low-boron low-heavy-rare-earth high-coercivity sintered neodymium-iron-boron permanent magnet

A high coercive force, neodymium iron boron technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of high equipment requirements, shallow infiltration diffusion depth, aggravated rare earth elements, etc., to achieve enhanced Anti-corrosion performance and processing performance, improve the efficiency of infiltration, and avoid the effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

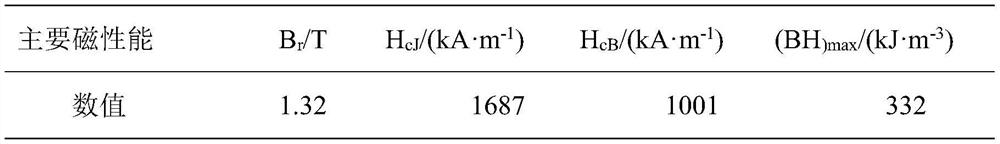

Embodiment 1

[0028] A method for preparing a low-boron, low-heavy, rare-earth, high-coercivity sintered NdFeB permanent magnet, comprising the following steps:

[0029] 1. Using rare earth metal neodymium, rare earth metal praseodymium, metal iron, metal cobalt, metal copper, metal aluminum, and boron-iron alloy with a purity greater than 99.5% and an oxygen content of less than 250ppm as raw materials, according to (Nd 23.4% PR 5.5% ) 28.9% (Fe 68.62% co 0.8% Cu 0.5% Al 0.3% ) 70.22% B 0.88% The composition design of the main phase alloy is carried out. After the quick-setting flakes are made by the quick-setting flake process, they are crushed by the hydrogen crushing method and crushed by a jet mill to make a powder of 1.5-3.5 μm;

[0030] 2. Rare earth metal neodymium, rare earth metal lanthanum, metal iron, ferro-niobium alloy, and dysprosium carbonate with a purity greater than 99.5% are used as raw materials, according to {Nd 40% La 6.5% [Dy 2 (CO 3 ) 3 ] 9.65%} 56.15%...

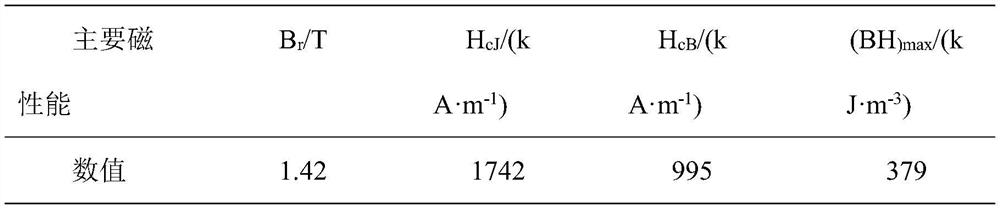

Embodiment 2

[0039] A method for preparing a low-boron, low-heavy, rare-earth, high-coercivity sintered NdFeB permanent magnet, comprising the following steps:

[0040] 1. Rare earth metal neodymium, rare earth metal praseodymium, rare earth metal lanthanum, metal iron, metal cobalt, metal aluminum, and boron-iron alloy with a purity greater than 99.5% and an oxygen content of less than 300ppm are used as raw materials, according to (Nd 22.7% PR 4.5% La 2.4% ) 29.6% (Fe 67.83% co 1.2% al 0.5% ) 69.53% B 0.87% The composition design of the main phase alloy is carried out. After the quick-setting flakes are made by the quick-setting flake process, they are crushed by the hydrogen crushing method and crushed by a jet mill to make a powder of 1.5-3.5 μm;

[0041] 2. Rare earth metal neodymium, rare earth metal lanthanum, metal iron, ferro-niobium alloy, metal cobalt, and dysprosium carbonate with a purity greater than 99.5% are used as raw materials, according to {Nd 35% La 8.25% [Dy ...

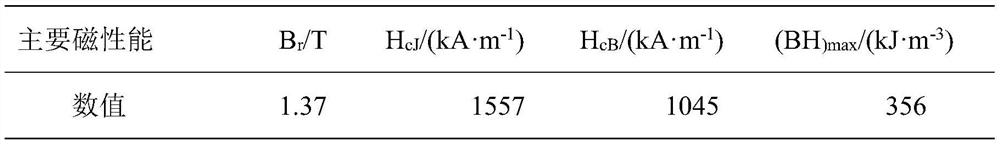

Embodiment 3

[0050] A method for preparing a low-boron, low-heavy, rare-earth, high-coercivity sintered NdFeB permanent magnet, comprising the following steps:

[0051] 1. Rare earth metal neodymium, rare earth metal praseodymium, metal iron, metal cobalt, niobium-iron alloy, and boron-iron alloy with a purity greater than 99.5% and an oxygen content of less than 200ppm are used as raw materials, according to (Nd 26.65% PR 2.5% ) 29.15% (Fe 67.9% co 1.5% Nb 0.6% ) 70% B 0.85% The composition design of the main phase alloy is carried out. After the quick-setting flakes are made by the quick-setting flake process, they are crushed by the hydrogen crushing method and crushed by a jet mill to make a powder of 1.5-3.5 μm;

[0052] 2. Rare earth metal neodymium, rare earth metal lanthanum, metal iron, ferro-niobium alloy, metal cobalt, and terbium carbonate with a purity greater than 99.5% are used as raw materials, according to {Nd 43.72% [Tb 2 (CO 3 ) 3 ] 8.5%} 52.22% (Fe 42.28% N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com