Slow-release long-acting skin-whitening sunblock and preparation method thereof

A sunscreen, long-acting technology, applied in the directions of medical formulations, pharmaceutical formulations, cosmetic formulations containing active ingredients, etc., can solve the problems of easy skin irritation, short effective time of sunscreen, unsatisfactory sunscreen effect, etc., and achieve skin irritation. Less sex, longer effective sunscreen time, enhanced whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

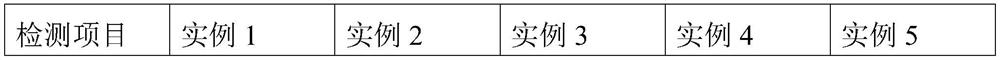

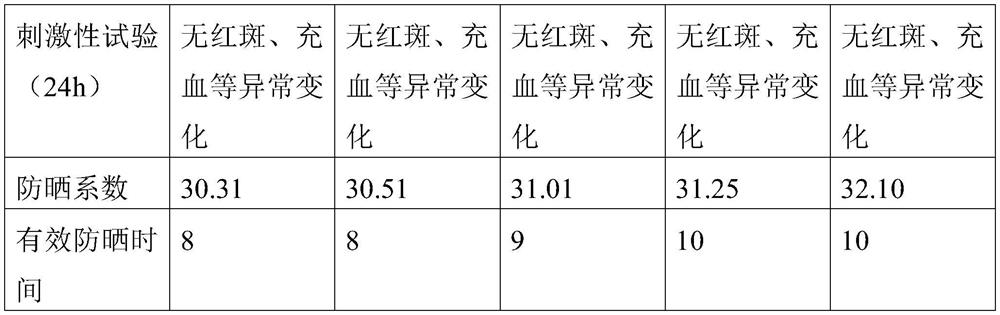

Examples

example 1

[0065] Weigh the pearls and put them into a pulverizer to crush them and pass through a 200-mesh sieve to collect the pearl powder. Mix the obtained pearl powder and castor oil in a mass ratio of 2:1 and spread them on a stainless steel tray, then move the stainless steel tray into the temperature temperature of 45°C and a relative air humidity of 60% in a greenhouse, the rancidity treatment was left to stand for 7 days; after the above-mentioned rancidity treatment was completed, the rancidity product was repeatedly washed with absolute ethanol and deionized water for 3 times. Put it into the oven, heat up to 60°C, and dry it for 1 hour to obtain acid-etched porous pearl powder, which is ready for use; the mixed silk raw material of the pupal lining and the cut cocoon is 0.5mol / L according to the mass ratio of 5:6. mixed sodium carbonate solution, degummed at 70°C for 1 hour, after the degumming was completed, the silk fibers were washed with water and then dried to obtain deg...

example 2

[0067] Weigh the pearls and put them into a pulverizer to crush them and pass through a 200-mesh sieve to collect the pearl powder. Mix the obtained pearl powder and castor oil in a mass ratio of 2:1 and spread them on a stainless steel tray, then move the stainless steel tray into the temperature temperature of 48°C and a relative air humidity of 62%, the rancidity treatment was left to stand for 8 days; after the above-mentioned rancidity treatment was completed, the rancidity product was repeatedly washed with absolute ethanol and deionized water for 3 times. Put it in the oven, heat up to 62°C, and dry it for 2 hours to obtain acid-etched porous pearl powder, which is ready for use; the mixed silk raw material of the pupal lining and the cut cocoon is 0.5mol / L according to the mass ratio of 5:6. Mix the sodium carbonate solution, degumming at 72 DEG C for 1 hour, after the degumming is completed, wash the silk fiber with water and dry to obtain the degummed silk fiber; the ...

example 3

[0069] Weigh the pearls and put them into a pulverizer to crush them and pass through a 200-mesh sieve to collect the pearl powder. Mix the obtained pearl powder and castor oil in a mass ratio of 2:1 and spread them on a stainless steel tray, then move the stainless steel tray into the temperature In a greenhouse at 49°C and a relative air humidity of 65%, the rancidity treatment was left to stand for 8 days; after the above-mentioned rancidity treatment was completed, the rancidity product was repeatedly washed with absolute ethanol and deionized water for 4 times. Put it into the oven, heat up to 63°C, and dry it for 1 hour to obtain acid-etched porous pearl powder, which is ready for use; the mixed silk raw material of the pupal lining and the cut cocoon is 0.5mol / L according to the mass ratio of 5:6. mixed sodium carbonate solution, and degummed at 73° C. for 1 hour. After the degumming was completed, the silk fibers were washed with water and then dried to obtain degummed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com