A hydrogen sensor with ppb level detection lower limit and preparation method thereof

A sensor and hydrogen technology, applied in the field of sensors, can solve the problems of limiting the test range of sensors, damage of Pd film, sudden change of electrical properties, etc., and achieve the effects of humidity stability and selective application, wide test range, and room temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

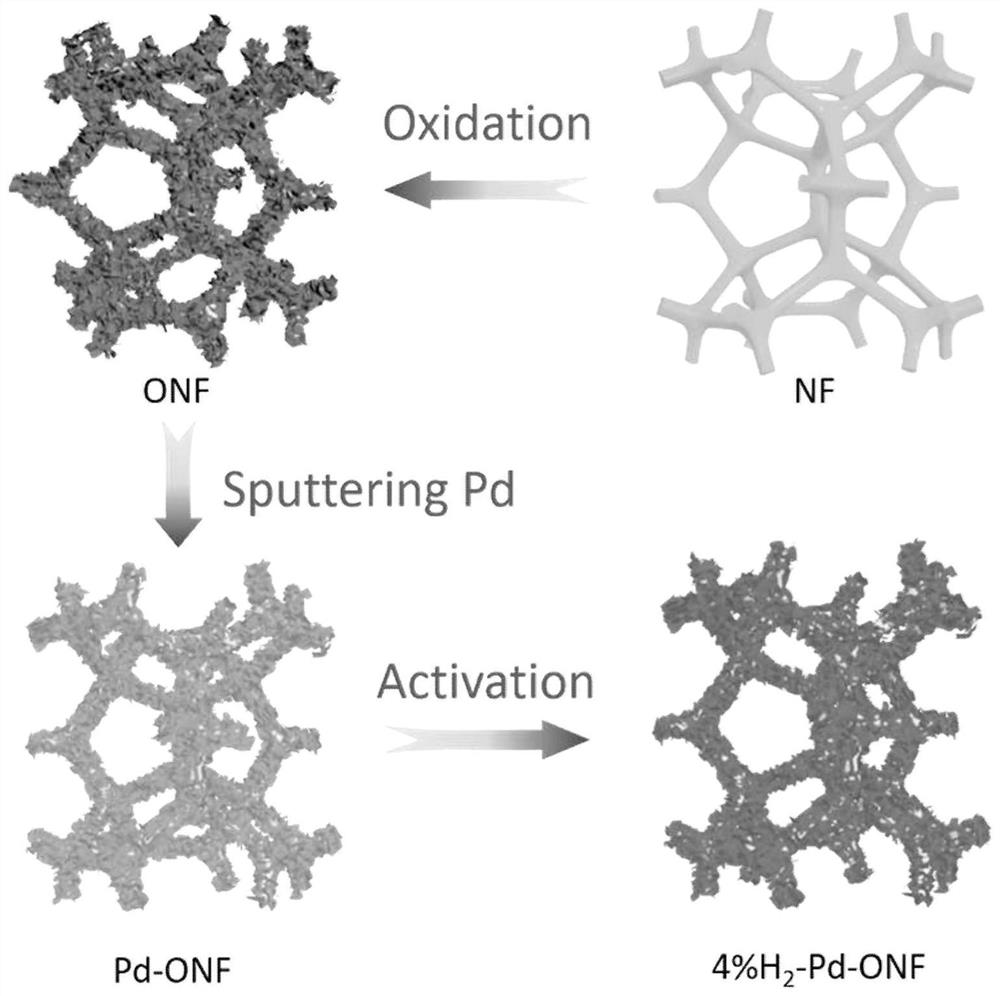

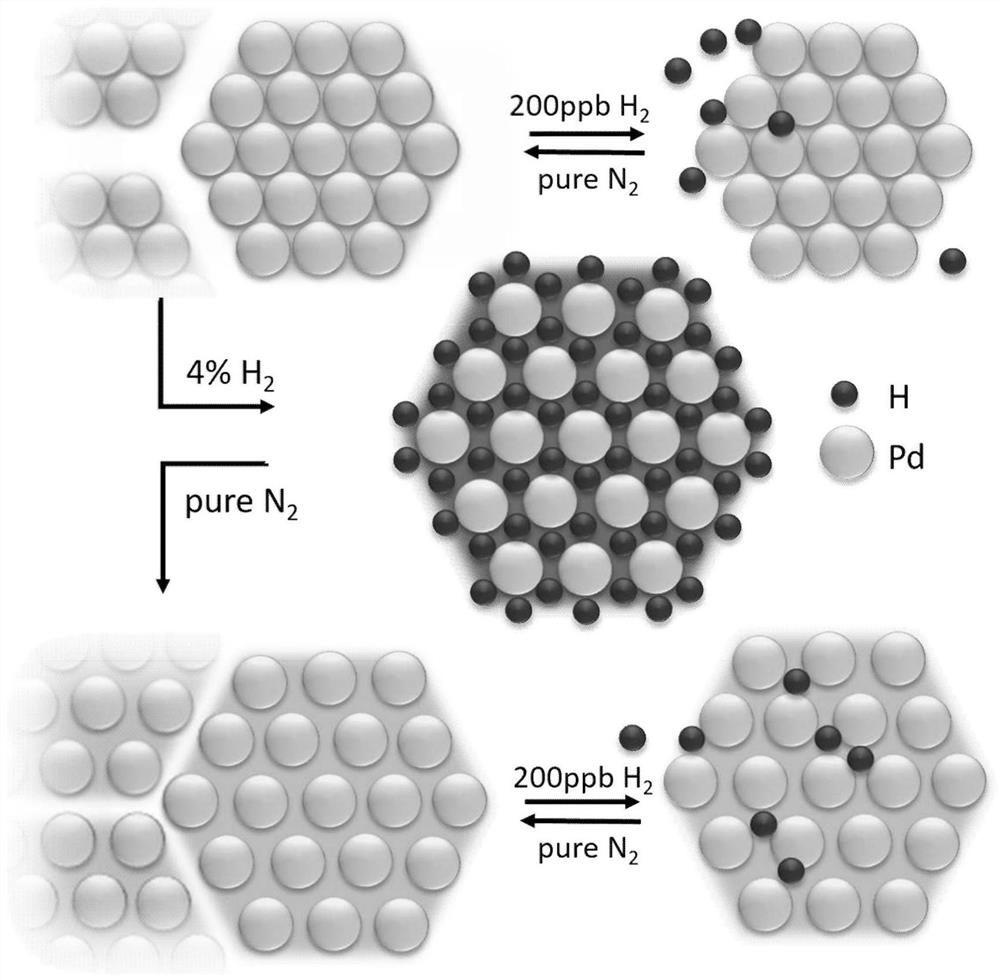

[0036] A method for preparing a hydrogen sensor with a ppb level detection lower limit, characterized in that it comprises the following steps:

[0037] Step 1, cutting the metal foam to a suitable size, cleaning with deionized water, absolute ethanol and acetone in turn, and drying; the metal foam is nickel foam, copper foam, zinc foam, aluminum foam, cobalt foam, etc., the foam The thickness of the metal is 0.1mm ~ 1mm, and the porosity is above 98%;

[0038] Step 2. Heat-treat the metal foam after cleaning and drying in step 1 in an air atmosphere. The heat treatment temperature is 500-1000° C., and the heat-treatment time is 3-6 hours. After completion, naturally cool to room temperature and take it out to obtain oxidized metal foam;

[0039] Step 3, using the DC magnetron sputtering method, sputtering the surface of the oxidized metal foam obtained in step 2 to obtain Pd nanoparticles with a particle size of 5nm to 10nm, wherein the sputtering rate is 8nm / min, and the spu...

Embodiment 1

[0047] A preparation and activation method of a ppb-level detection lower limit hydrogen sensor, the specific steps are:

[0048] Step 1. Select nickel foam with a thickness of 0.3mm and a porosity of 98%, cut the nickel foam into small squares of 3mm×8mm, and then ultrasonically clean it in deionized water, absolute ethanol and acetone for 15 minutes;

[0049] Step 2. Heat-treat the nickel foam after step 1 has been cleaned and dried in an air atmosphere. The heat-treatment temperature is 800° C. and the heat-treatment time is 3 hours. After completion, naturally cool to room temperature and take it out to obtain oxidized nickel foam;

[0050] Step 3, adopting DC magnetron sputtering, sputtering on the surface of oxidized nickel foam obtained in step 2 to obtain Pd nanoparticles with a particle size of about 8nm, wherein the sputtering rate is 8nm / min, and the sputtering time is 180s. The shooting target is pure Pd (99.9995wt%) target;

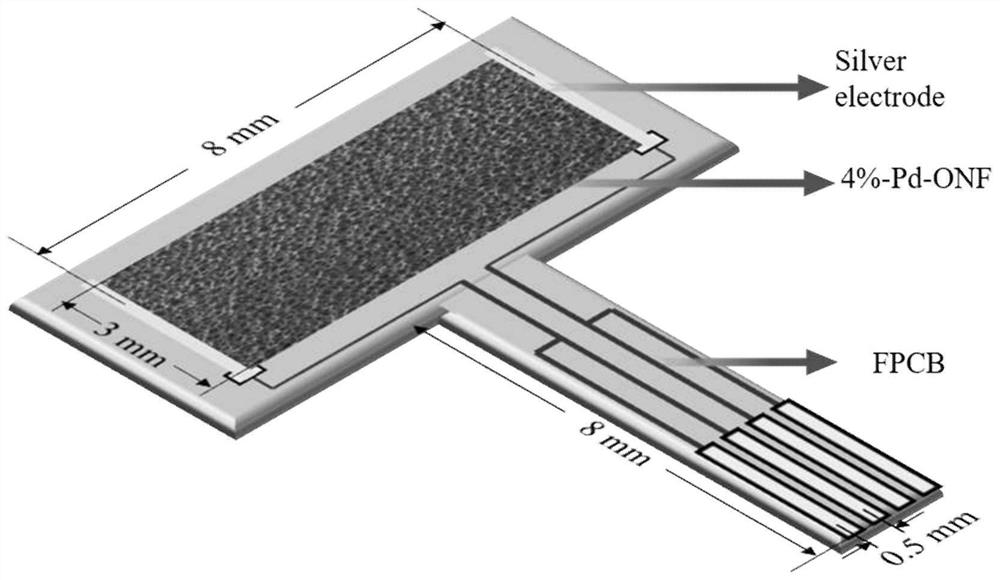

[0051] Step 4, the two ends of the ox...

Embodiment 2

[0058] A preparation and activation method of a ppb-level detection lower limit hydrogen sensor, the specific steps are:

[0059] Step 1. Select foamed copper with a thickness of 0.5mm and a porosity of 98%, cut the foamed copper into small squares of 3mm×8mm, and then ultrasonically clean it in deionized water, absolute ethanol and acetone for 15 minutes;

[0060] Step 2. Heat-treat the copper foam after cleaning and drying in step 1 in an air atmosphere. The heat-treatment temperature is 650° C. and the heat-treatment time is 6 hours. After completion, naturally cool to room temperature and take it out to obtain oxidized copper foam;

[0061] Step 3, adopting DC magnetron sputtering, sputtering the surface of the oxidized copper foam obtained in step 2 to obtain Pd nanoparticles with a particle size of about 8nm, wherein the sputtering rate is 8nm / min, and the sputtering time is 180s. The shooting target is pure Pd (99.9995wt%) target;

[0062] Step 4, the two ends of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com