Positive photosensitive polyimide resin composition and application thereof

A technology of polyimide resin and composition, applied in optics, opto-mechanical equipment, photosensitive materials for opto-mechanical equipment, etc., can solve the damage of circuit board substrate material, unfavorable film quality, harsh production conditions, etc. problems, to achieve the effect of meeting performance requirements, simple cleaning and processing processes, and wide application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] Preparation of photosensitive polyimide varnish: mix the obtained alkali-soluble polyimide resin A component and B component according to the required ratio, add methylimidazole, epoxy resin crosslinking agent and phenolic resin, and add Solvent γ-butyrolactone, stirring and dissolving at room temperature, after the dissolution is uniform, add a certain amount of diazide quinone compound under dark light, stir and dissolve, dissolve evenly and filter to obtain photosensitive polyimide varnish, dark light Save for later.

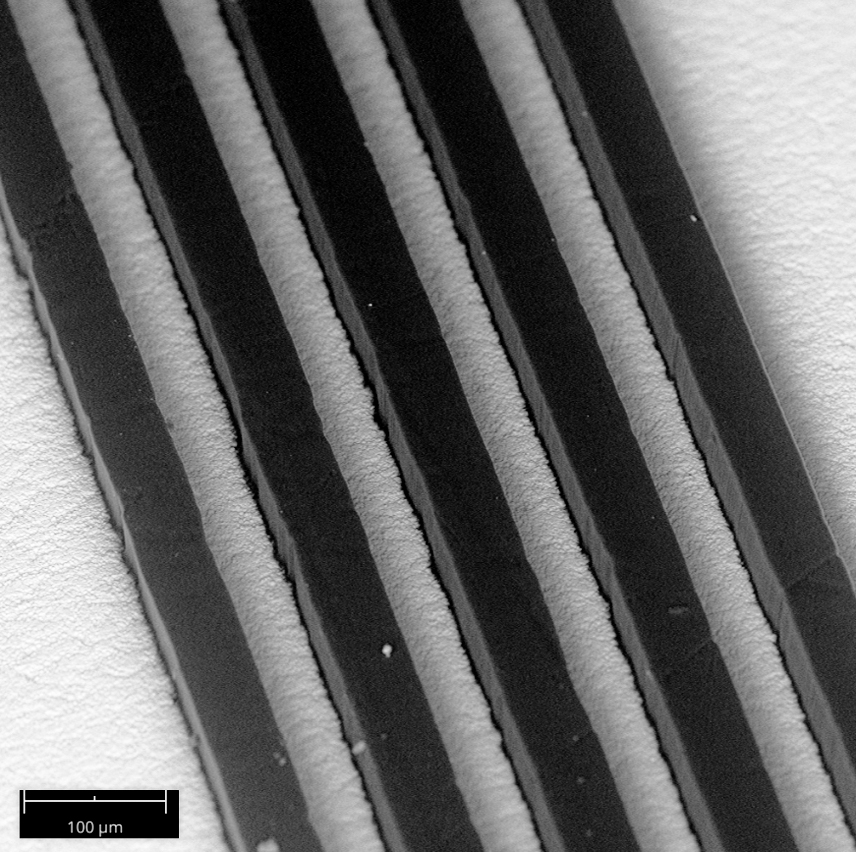

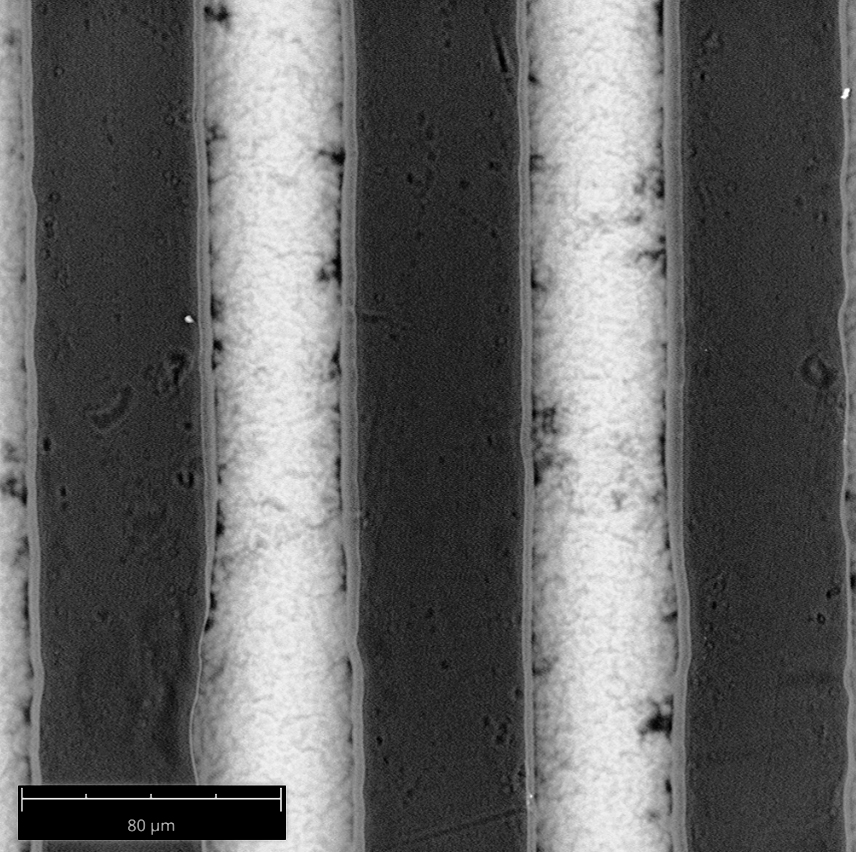

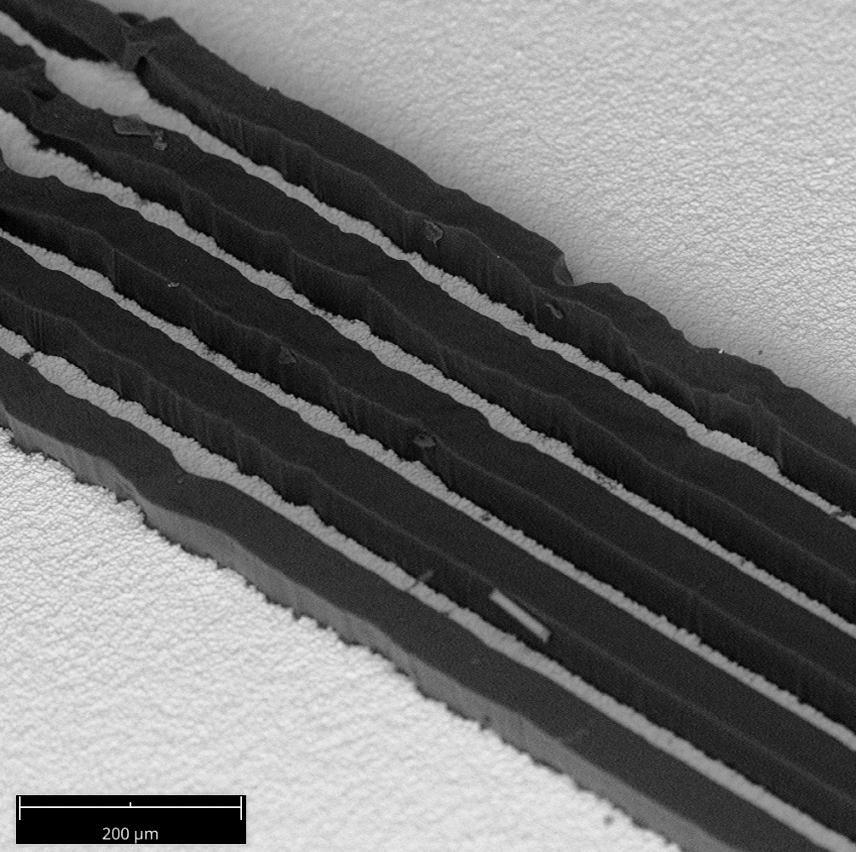

[0066] Coating, exposure, development and curing of photosensitive polyimide, the specific steps are as follows: first, the film is coated by spin coating, followed by pre-baking, pre-baking for 10 min (100°C), and pre-baking is completed After that, the exposure was carried out immediately, and the exposure time was 3 min. Then the development experiment was carried out, the development time was 3min, and then the developed sample was heated to 140°C f...

Embodiment 1

[0068] Under dry nitrogen flow, first dissolve 3.66 g (10 mmol) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (hereinafter referred to as 6FAP) in 8 g of γ-butyrolactone (GBL ), followed by adding 3.00 g (9.68 mmol) of bis(3,4-dicarboxyphenyl) ether dianhydride (ODPA), and then adding 2 g of GBL, allowing it to react at 10 °C for 4 h. Then a certain amount of toluene was added and stirred at 180 °C for 4 h. After stirring, the solution was poured into 300 mL of water to obtain a yellowish precipitate. The precipitate was collected by filtration, washed three times with water, then washed three times with hot alcohol water, and finally dried in a vacuum dryer at 80 °C for 12 h to obtain a slightly yellow alkali-soluble polyimide. The powder (A-1) of the amine resin had a yield of 90% and a degree of imidization of 95%.

[0069] Under dry nitrogen flow, first dissolve 3.66 g (10 mmol) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (hereinafter referred to as 6FA...

Embodiment 2

[0073] Under dry nitrogen flow, first dissolve 3.66 g (10 mmol) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (hereinafter referred to as 6FAP) in 8 g of γ-butyrolactone (GBL ), followed by adding 3.06 g (9.87 mmol) of bis(3,4-dicarboxyphenyl) ether dianhydride (ODPA), and then adding 2 g of GBL, allowing it to react at 10 °C for 4 h. Then a certain amount of toluene was added and stirred at 180 °C for 4 h. After stirring, the solution was poured into 300 mL of water to obtain a yellowish precipitate. The precipitate was collected by filtration, washed three times with water, then washed three times with hot alcohol water, and finally dried in a vacuum dryer at 80 °C for 12 h to obtain a slightly yellow alkali-soluble polyimide. Amine resin powder (A-2) had a yield of 94% and a degree of imidization of 91%.

[0074] Under dry nitrogen flow, first dissolve 3.66 g (10 mmol) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane (hereinafter referred to as 6FAP) in 8 g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com