Fluorescent ceramic as well as preparation method and application thereof

A technology for fluorescent ceramics and ceramic china, applied in chemical instruments and methods, electric light sources, luminescent materials, etc., can solve problems such as major breakthroughs in laser performance, and achieve good laser saturation performance, high luminous efficiency, and huge application potential. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

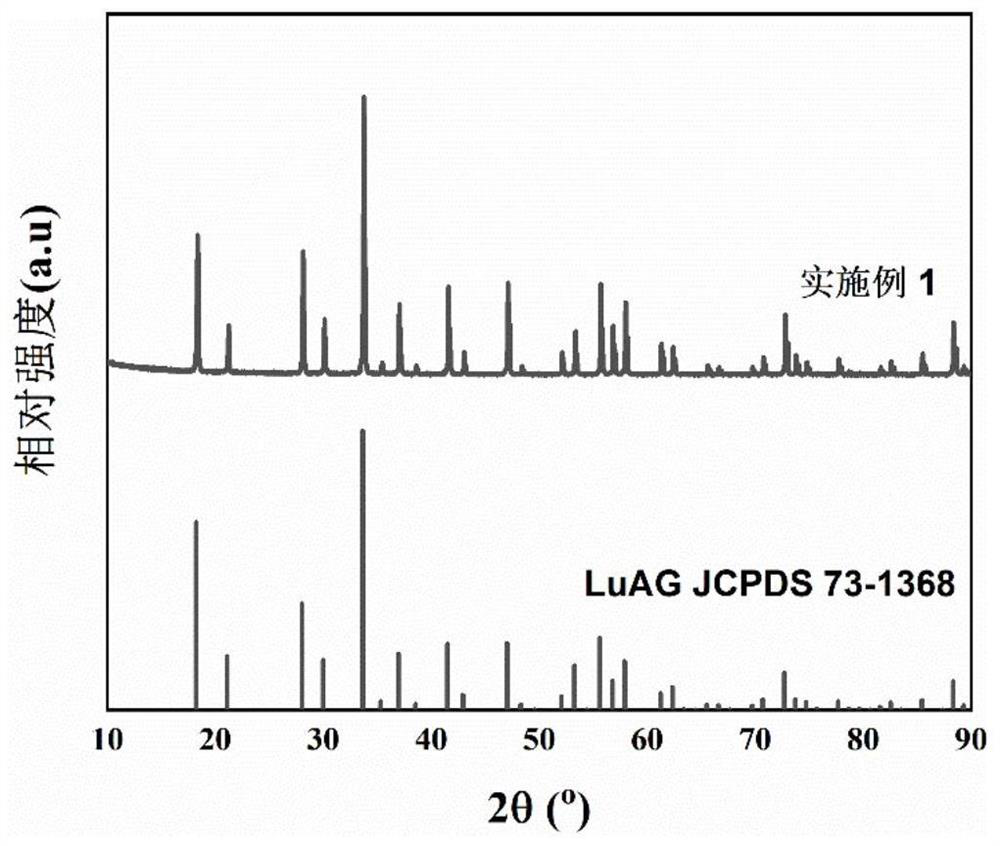

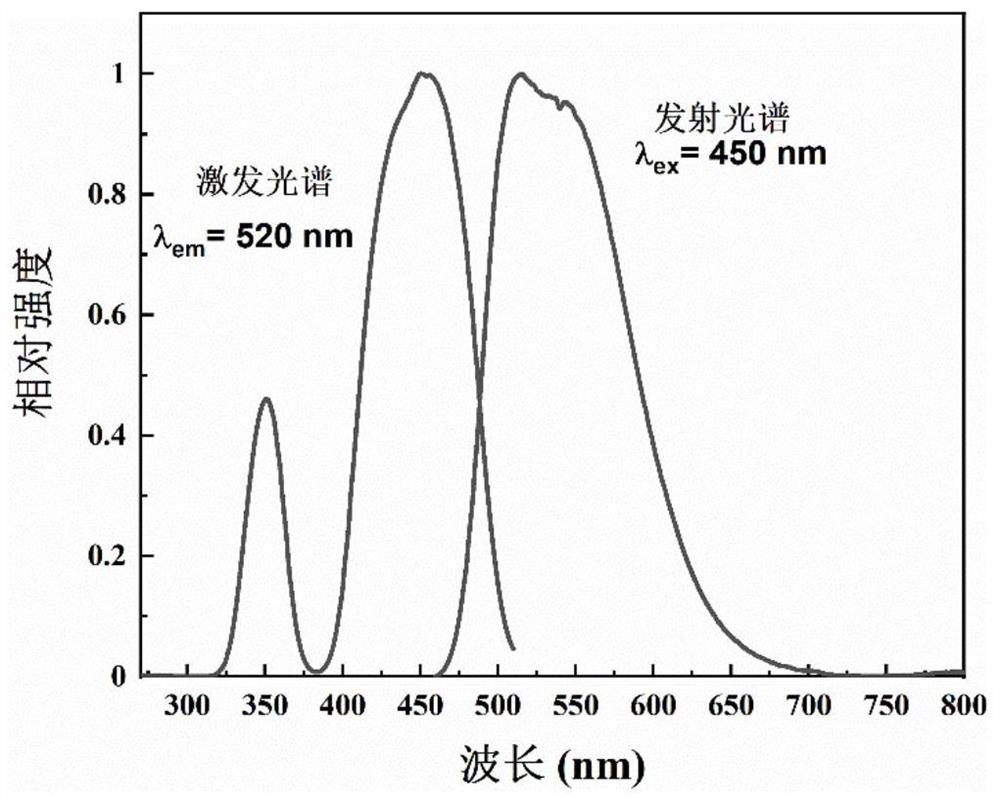

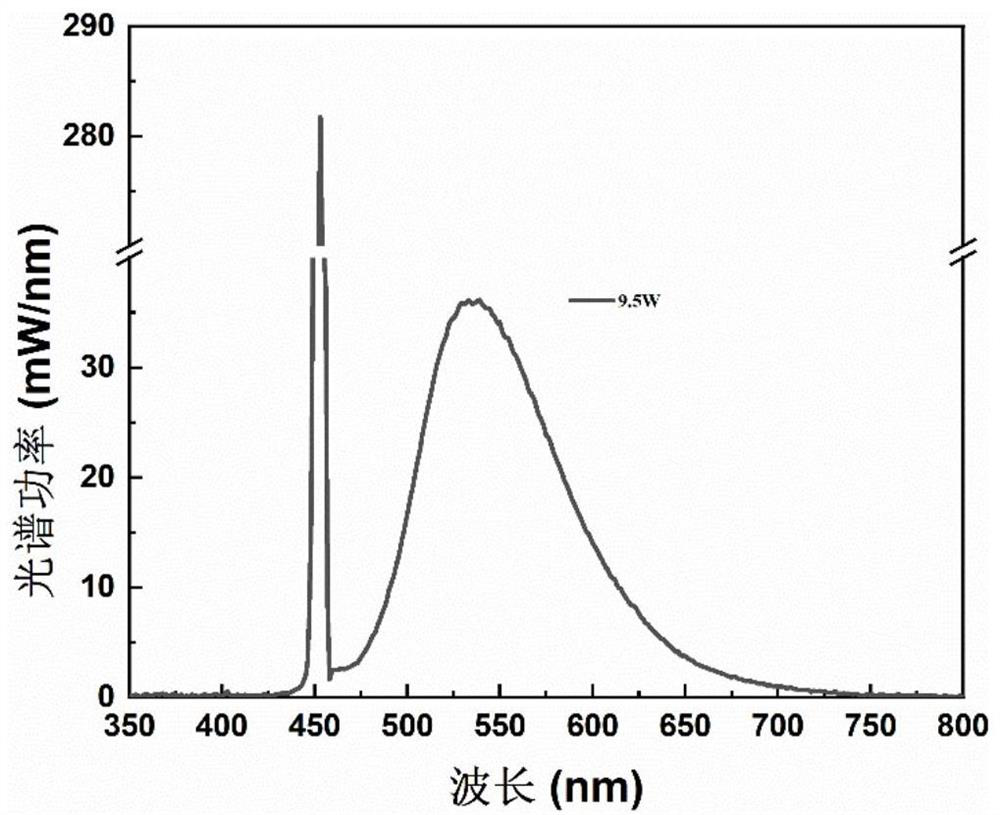

[0104] Lu 2.975 Ce 0.005 Ba 0.02 al 4.98 Si 0.02 o 12 (x=0.005, y=0.02) and preparation method thereof

[0105] Activated ion Ce 3+ The concentration is 0.5at.%, Ba 2+ and Si 4+ The doping concentration is 2 at.%. Commercially available Lu with a purity of 99.99% 2 o 3 , Al 2 o 3 , CeO 2 , BaCO 3 and SiO 2 Raw material powder according to stoichiometric ratio Lu 2.975 Ce 0.005 Ba 0.02 al 4.98 Si 0.02 o 12 Weigh it, use absolute ethanol as the ball milling medium, and mill it on a high-energy ball mill for 30 hours at a ball milling speed of 60 rpm / min. The ball-milled slurry was dried and sieved, followed by dry pressing and cold isostatic pressing to obtain a ceramic green body. The green body was sintered in a hot-press furnace at a temperature of 1750°C and a pressure of 50 MPa for 5 hours. The sintered ceramic samples were annealed in a carbon monoxide atmosphere at 1450°C for 10 hours, then mechanically thinned and polished to obtain LuAG: 0.5% Ce, 2...

Embodiment 2

[0107] Lu 2.989 Ce 0.001 Ba 0.01 al 4.99 Si 0.01 o 12 (x=0.001, y=0.01) and preparation method thereof

[0108] Activated ion Ce 3+ The concentration is 0.1at.%, Ba 2+ and Si 4+ The doping concentration is 1 at.%. Commercially available Lu with a purity of 99.99% 2 o 3 , Al 2 o 3 , CeO 2 , BaCO 3 and SiO 2 Raw material powder according to stoichiometric ratio Lu 2.989 Ce 0.001 Ba 0.01 al 4.99 Si 0.01 o 12 Weigh, use absolute ethanol as the ball milling medium, and mill at a milling speed of 120 rpm / min for 15 hours. The ball-milled slurry was dried and sieved, followed by dry pressing and cold isostatic pressing to obtain a ceramic green body. The green body was sintered in a vacuum furnace at a temperature of 1800°C for 5 hours. The ceramic samples obtained by vacuum sintering were annealed in an air atmosphere at 1500°C for 8 hours, then mechanically thinned and polished to obtain LuAG: 0.1% Ce, 1% Ba, 1% Si fluorescent transparent ceramics with a diame...

Embodiment 3

[0110] Lu 2.975 Ce 0.015 Ba 0.005 Mg 0.005 al 4.99 Si 0.01 o 12 (x=0.015, y=0.01) and preparation method thereof

[0111] Activated ion Ce 3+ The concentration is 1.5at.%, Ba 2+ with Mg 2+ The concentration of combined doping is 0.5at.% and 0.5at.%, respectively, Si 4+ The doping concentration is 1 at.%. Commercially available Lu with a purity of 99.99% 2 o 3 , Al 2 o 3 , Ce 2 (CO 3 ) 3 , BaCO 3 , MgO and SiO 2 Raw material powder according to Lu 2.975 Ce 0.015 Ba 0.005 Mg 0.005 al 4.99 Si 0.01 o 12 The chemical formula was weighed, and absolute ethanol was used as the ball milling medium, and ball milled on a high-energy ball mill for 5 hours with a ball milling speed of 300 rpm / min. After the ball-milled slurry was dried and sieved, the ceramic green body was obtained by dry pressing and cold isostatic pressing in sequence, and the green body was sintered in a vacuum furnace at a sintering temperature of 1750°C for 20 hours. The ceramic sample obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Ll | aaaaa | aaaaa |

| Lumen efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com