A Lossless Rapid Separation Method of Single Crystal Diamond and Substrate

A single crystal diamond and separation method technology, which is applied in the field of lossless and fast separation of single crystal diamond and substrate, can solve the problems of high price, long growth cycle, loss of diamond, etc., shorten the corrosion cycle, improve separation efficiency, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

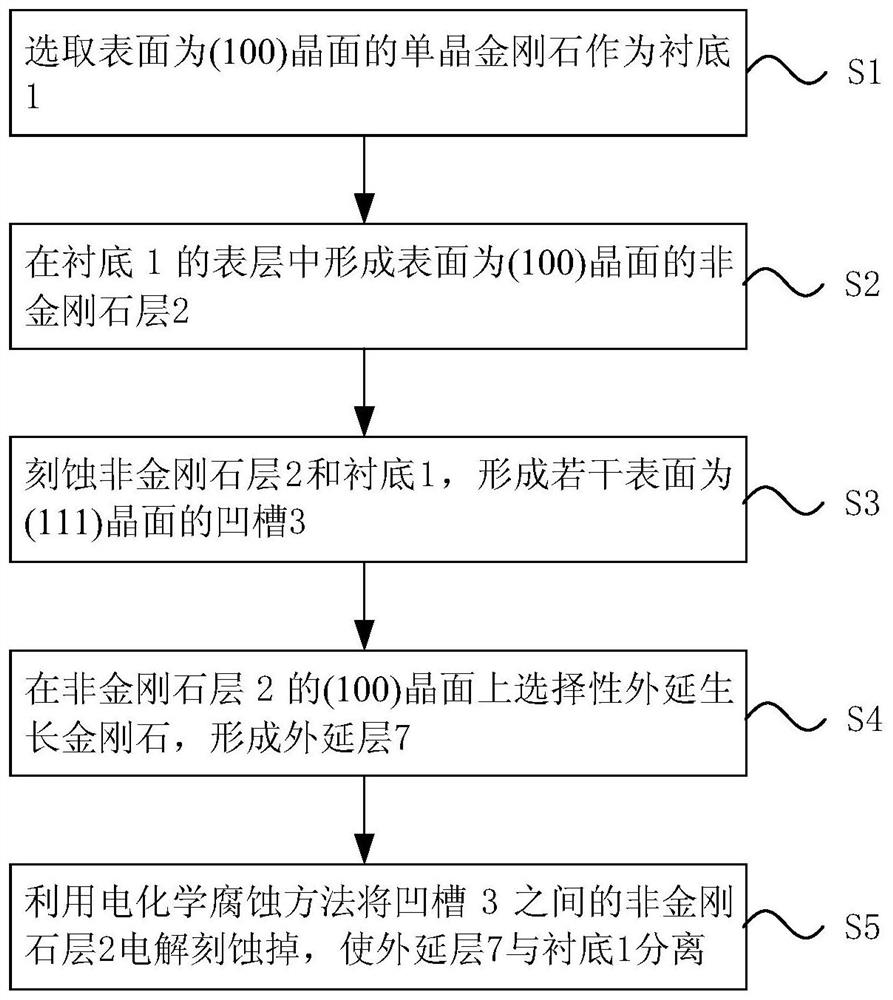

[0034] See figure 1 and Figure 2, figure 1 A schematic flow chart of a lossless and fast separation method for single crystal diamond and substrate provided by an embodiment of the present invention, Figure 2a-Figure 2h It is a process schematic diagram of a lossless and rapid separation method for single crystal diamond and a substrate provided by an embodiment of the present invention. The separation method comprises the steps of:

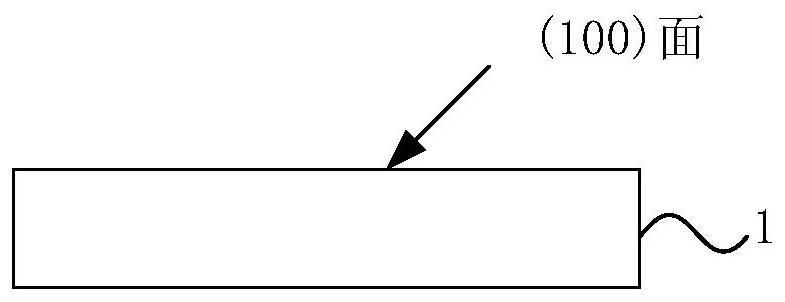

[0035] S1. Select the single crystal diamond whose surface is the (100) crystal plane as the substrate 1, please refer to Figure 2a .

[0036] Specifically, a single crystal diamond sheet whose surface is a (100) crystal plane synthesized by High Temperature and High Pressure (HTHP) is selected as the substrate 1 . In this embodiment, as long as the upper surface of the single crystal diamond sheet is a (100) crystal plane, there is no restriction on the side and lower surfaces of the single crystal diamond sheet, and its side and lower sur...

Embodiment 2

[0061] On the basis of Embodiment 1, this embodiment will illustrate the lossless separation method by taking the substrate 1 with a separation groove depth of 10 μm and the epitaxial layer 7 with 500 μm as an example.

[0062] Please combine figure 1 and Figure 2a-Figure 2h , the lossless separation method comprises steps:

[0063] S1. A single crystal diamond whose surface is a (100) crystal plane is selected as the substrate 1 .

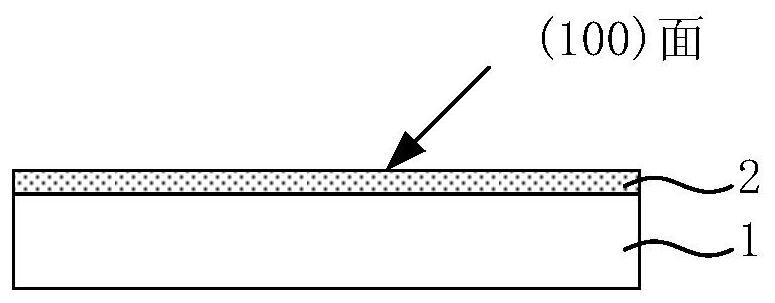

[0064] S2. Forming a non-diamond layer 2 with a (100) crystal plane on the surface of the substrate 1 .

[0065] S3. Etching the non-diamond layer 2 and the substrate 1 to form several grooves 3 whose surfaces are (111) crystal planes.

[0066] Spin-coat photoresist 4 on the surface of non-diamond layer 2, and make window pattern 5 on the photoresist by contact photolithography; then prepare a layer on the surface of photoresist 4 and non-diamond layer 2 by metal evaporation 300nm thick nickel metal, the metal on the photoresist is peeled off...

Embodiment 3

[0073] On the basis of Embodiment 1, this embodiment will illustrate the lossless separation method by taking the substrate 1 with a separation groove depth of 15 μm and the epitaxial layer 7 with 1000 μm as an example.

[0074] Please combine figure 1 and Figure 2a-Figure 2h , the lossless separation method comprises steps:

[0075] S1. A single crystal diamond whose surface is a (100) crystal plane is selected as the substrate 1 .

[0076] S2. Forming a non-diamond layer 2 with a (100) crystal plane on the surface of the substrate 1 .

[0077] S3. Etching the non-diamond layer 2 and the substrate 1 to form several grooves 3 whose surfaces are (111) crystal planes.

[0078] Spin-coat photoresist 4 on the surface of non-diamond layer 2, and make window pattern 5 on the photoresist by contact photolithography; then prepare a layer on the surface of photoresist 4 and non-diamond layer 2 by metal evaporation 300nm thick nickel metal, the metal on the photoresist is peeled of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com