Method and system for echelon resource separation of tailings of stainless steel refining furnace

A technology for stainless steel and refining furnaces, which is applied in the field of graded resource separation of stainless steel refining furnace tailings, which can solve the problems of failure to realize the full utilization of high value-added closed resources of stainless steel refining furnace tailings, unstable cracking of building materials, and large dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

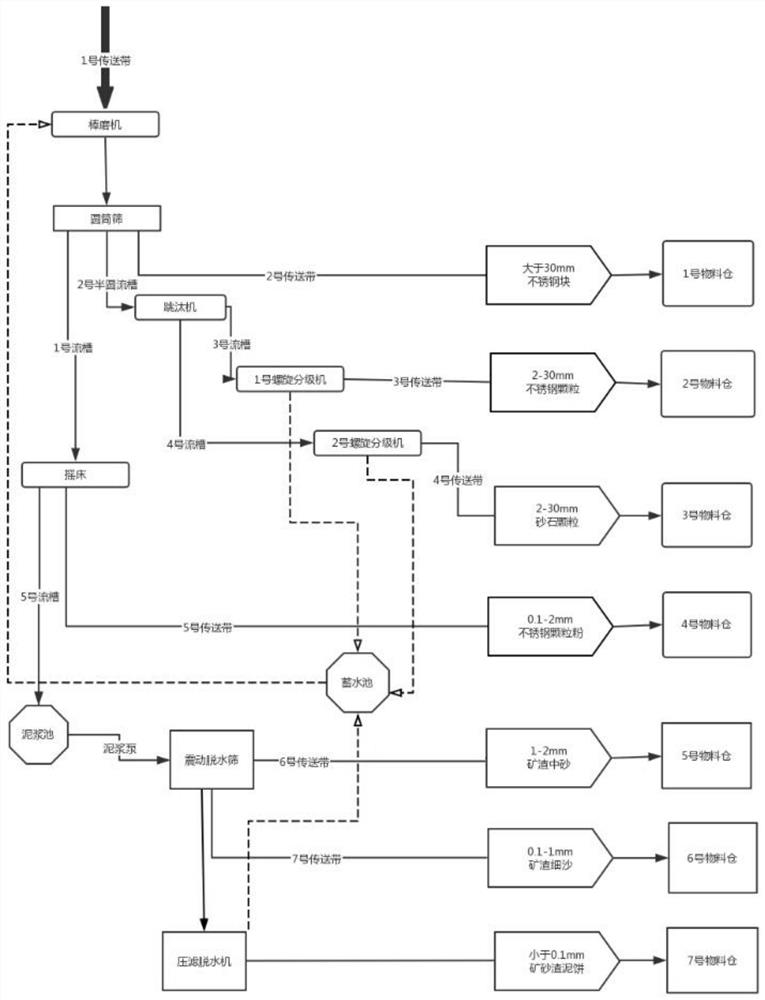

[0069] The tailings of the stainless steel refining furnace placed in the hopper are transported to the rod mill through the belt conveyor, and the tailings with a particle size of less than or equal to 50 mm are transported forward to the cylindrical screen connected to the rod mill;

[0070] The cylindrical sieve is composed of two horn-shaped cylindrical screens with a length of 1000m in series, and the first section of the cylindrical sieve and the second section of the cylindrical sieve are arranged in sequence according to the direction of material travel, wherein the first The diameter of the outlet of the cylindrical sieve is 1080mm, the size of the sieve gap is 2×30mm, the diameter of the outlet of the second cylindrical sieve is 1680mm, and the aperture of the screen is 2mm. The screening process is as follows: the material first passes through the first One section of cylindrical sieve, the material larger than 30mm cannot leak out, and is directly output; the materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com