Polyurethane composite foaming agent containing dialkyl carbonate

A technology of dialkyl carbonate and composite foaming agent, applied in the field of polyurethane foam preparation, can solve the problems of low flash point, difficult control of foaming reaction operation, unsuitable for polyurethane foam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

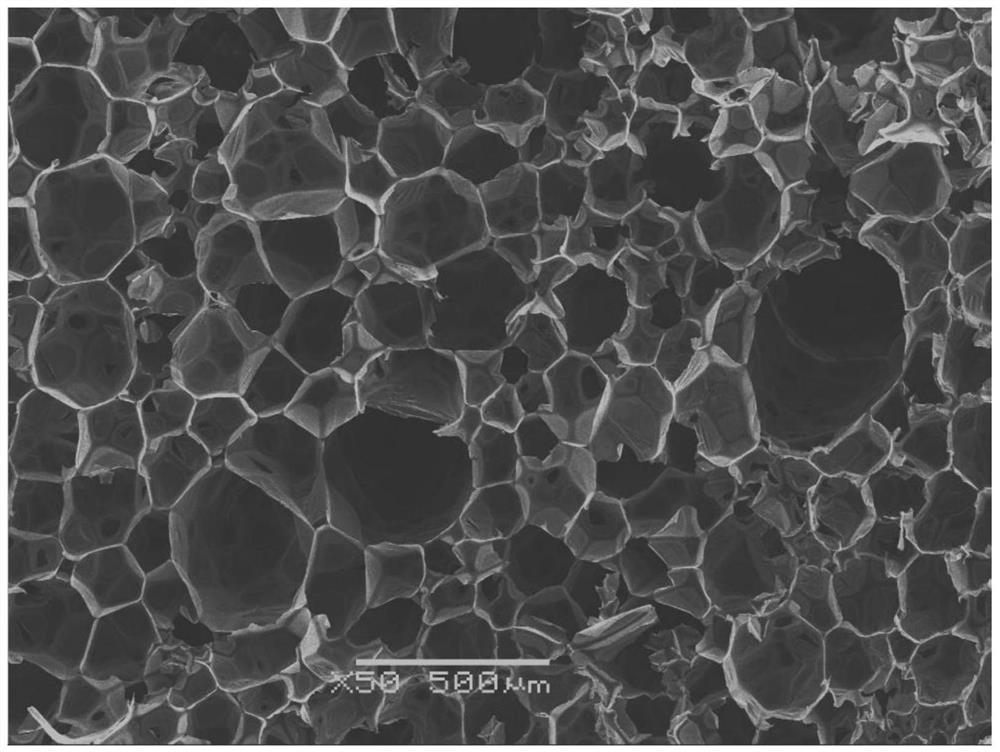

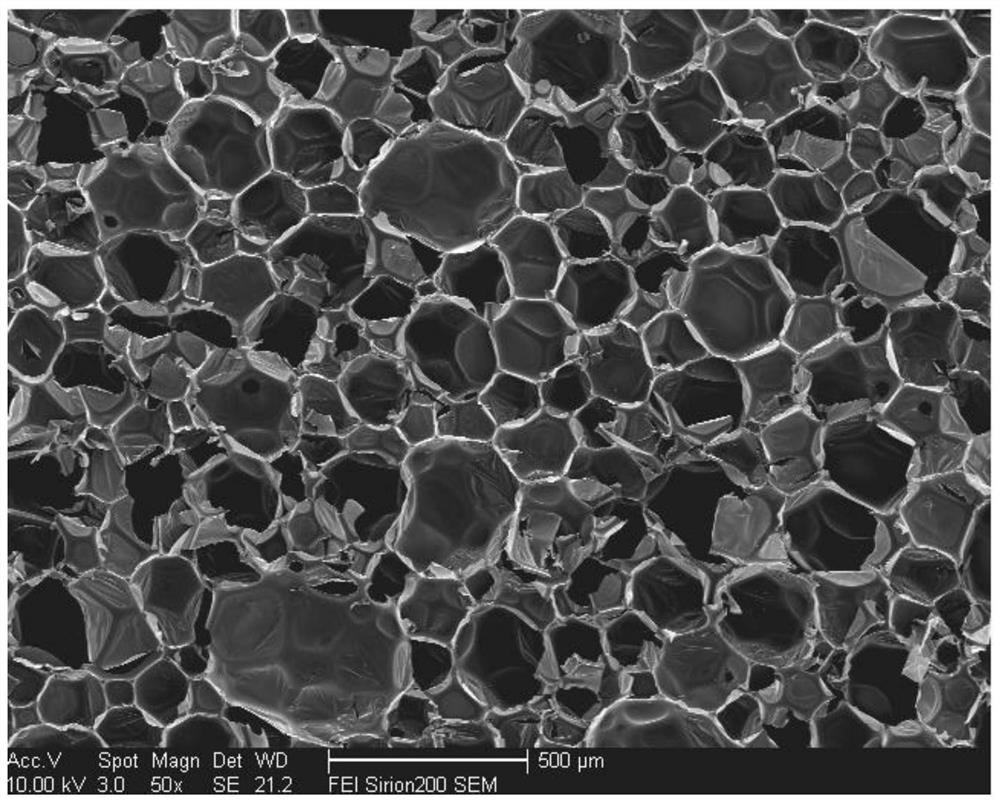

Image

Examples

Embodiment 1

[0149] Add 2000g of dimethyl carbonate into a 5L reaction kettle, start stirring, slowly pass the canned R134a into the reaction kettle at room temperature, and control the internal pressure of the reaction kettle below 0.2MPa. In the process of passing R134a into the reactor, it was observed that the outer surface of the outlet valve of the R134a storage tank had the phenomenon of freezing, but the temperature of dimethyl carbonate in the reactor gradually increased. After the temperature no longer rises, stop the introduction of R134a. After stopping the stirring and standing for 30 minutes, the pressure in the reactor was slowly released to normal pressure, and the material was discharged to obtain a composite foaming agent of about 2300g dimethyl carbonate and R134a.

Embodiment 2

[0151] Add 2000g of dimethyl carbonate into a 5L reactor, start stirring, slowly pour the canned R125 into the reactor at room temperature, and control the internal pressure of the reactor below 0.2MPa. In the process of passing R125 into the reactor, it was observed that the outer surface of the outlet valve of the R125 storage tank had icing, but the temperature of dimethyl carbonate in the reactor gradually increased. After the temperature no longer rises, stop the introduction of R125. After stopping stirring and standing for 30 minutes, slowly release the pressure in the reactor to normal pressure, and discharge to obtain a composite blowing agent of about 2400g dimethyl carbonate and R125.

Embodiment 3

[0153] Add 3000g of dimethyl carbonate into a 5L reactor, start stirring, slowly pass the canned R227ea into the reactor at room temperature, and control the pressure in the reactor below 0.2MPa. In the process of passing R227ea into the reactor, it was observed that the outer surface of the output valve of the R227ea storage tank was frozen, but the temperature of dimethyl carbonate in the reactor gradually increased. After the temperature no longer rises, stop the introduction of R227ea. After stopping the stirring and standing for 30 minutes, the pressure in the reactor was slowly released to normal pressure, and the material was discharged to obtain a composite blowing agent of about 3300g dimethyl carbonate and R227ea.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com