Fluorine-containing polymer for photoresist, top antireflection film composition containing same and application in photoresist

An anti-reflection film and polymer technology, applied in photosensitive materials for optomechanical equipment, optics, optomechanical equipment, etc., can solve problems such as processability, film-forming refractive index or insufficient raw material cost, and avoid standing Wave effect, reduce standing wave effect, produce easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation of perfluoropolyether carboxylic acid:

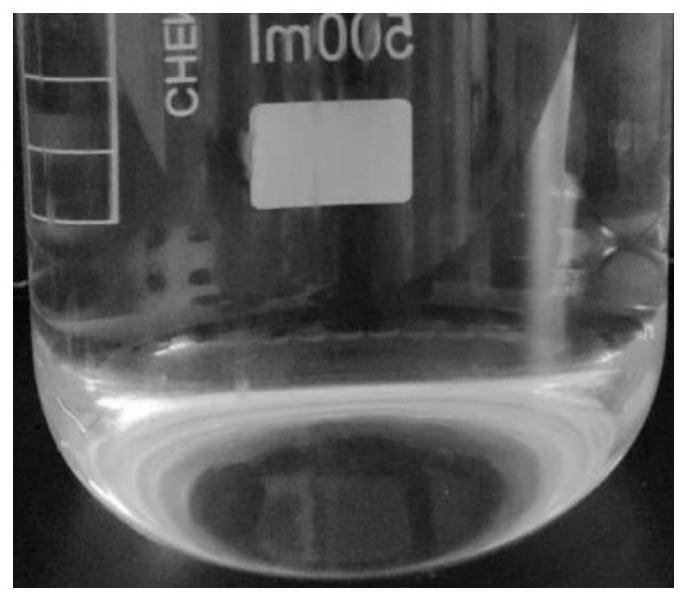

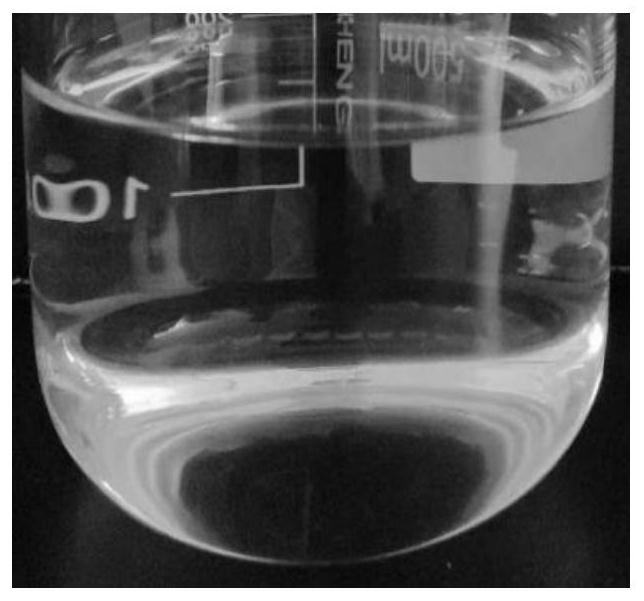

[0041] First add 50ml of acetonitrile and 50ml of tetraethylene glycol dimethyl ether into a 1L polymerization kettle, then add 5g of catalyst KF into the polymerization kettle, stir and mix evenly, replace with high-purity nitrogen three times, and pump negative pressure to -0.1MPa , cooled to the set temperature of 0°C, and 50g of hexafluoropropylene oxide was introduced. Timed feeding (50g / h) is adopted to control the reaction process, and the temperature is controlled between 0 and 10°C. After adding hexafluoropropylene oxide to 1000 g, return to normal pressure. After the reaction is complete, keep stirring for two hours, stop stirring, and return to room temperature to obtain a mixture.

[0042] The mixture is separated into layers, the reaction product in the lower layer is separated by centrifugation and filtration, and the reaction product is added to a distillation device. Perfluoropolyetheryl fluoride wit...

Embodiment 1

[0048] The above-mentioned perfluoropolyether carboxylic acids with different degrees of polymerization are mixed, and the mixing ratio is as follows: by weight, 10% perfluoropolyether carboxylic acid A, 66% perfluoropolyether carboxylic acid B, 19% perfluoropolyether carboxylic acid Ether carboxylic acid C, 1% perfluoropolyether carboxylic acid D, 4% perfluoropolyether carboxylic acid E. The perfluoropolyether carboxylic acid was thus obtained, the specific composition of which is shown in Table 1.

Embodiment 2

[0050] The above-mentioned perfluoropolyether carboxylic acids with different degrees of polymerization are mixed, and the mixing ratio is as follows: by weight, 4% perfluoropolyether carboxylic acid A, 58% perfluoropolyether carboxylic acid B, 28% perfluoropolyether carboxylic acid Ether carboxylic acid C, 8% perfluoropolyether carboxylic acid D, 2% perfluoropolyether carboxylic acid F. The perfluoropolyether carboxylic acid was thus obtained, the specific composition of which is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com