Carbon-azine composite water-based negative electrode material and application thereof

A composite material and negative electrode material technology, applied in the fields of carbonazine composite negative electrode materials and carbonazine composite water-based negative electrode materials, can solve the problems of poor long cycle life, poor rate performance, and high cost of large-scale energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

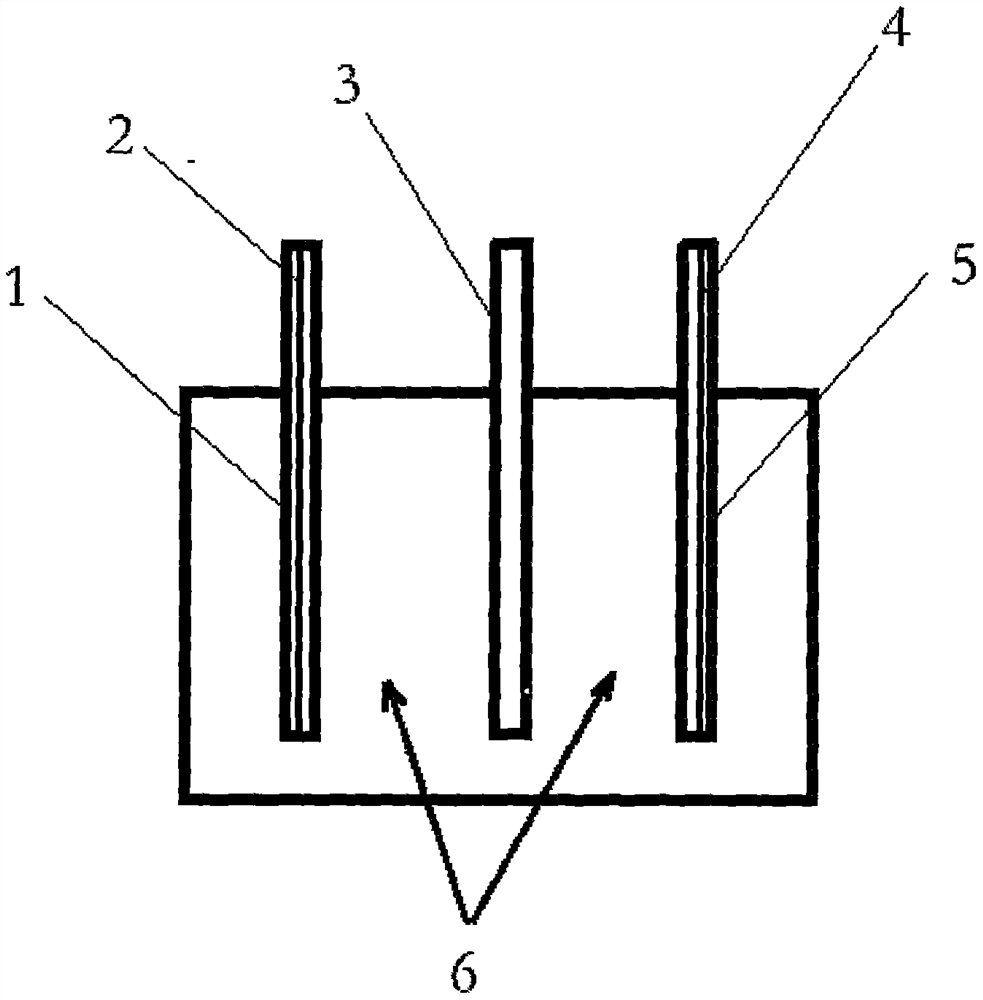

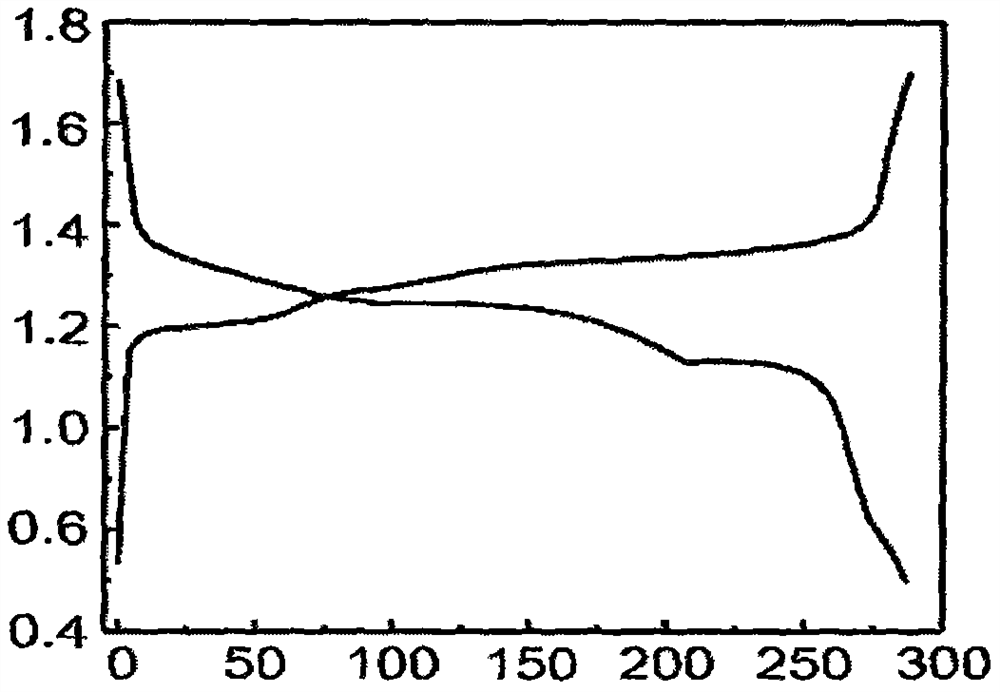

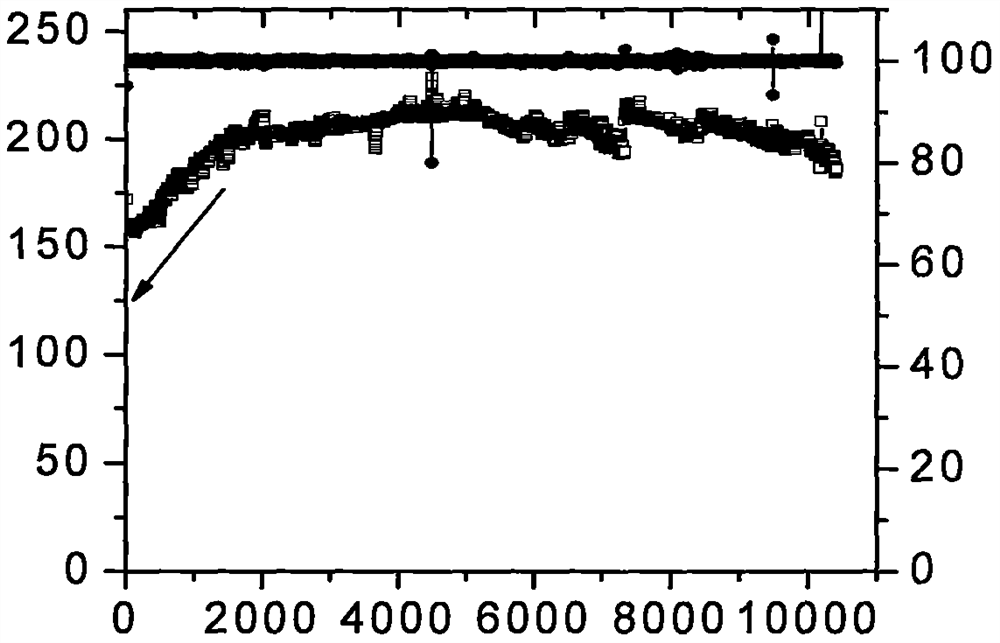

[0063] In a reactor equipped with 1g of conductive carbon black and 3g of phenazine, add 100ml of water, add 40ml of concentrated hydrochloric acid dropwise under stirring to completely dissolve phenazine, and then slowly add 8M NaOH strong alkali solution dropwise until the pH value is greater than or equal to 7 , and reacted at 25°C for 12 hours, the slowly precipitated phenazine and conductive carbon black were in-situ compounded to form a composite material, filtered, washed, and vacuum-dried at 50°C to obtain nanocarbazine with a phenazine content of 75%. composite material. Tested by the four-probe method, the conductivity of the carbon / oxine composite is 8S cm -1 .

[0064] The nanocarbazine composite negative electrode was mixed with acetylene black and polytetrafluoroethylene (PTFE) binder in water and ethanol according to the mass ratio of 90:5:5 to make a slurry, which was coated on the foamed nickel current collector, and air Dry at 393K for 6 hours to make elect...

Embodiment 2

[0066] In a reactor containing 6 g of phenazine, add 100 ml of a mixed solvent of water and ethanol, add 50 mL of concentrated sulfuric acid under magnetic stirring to completely dissolve the phenazine, and then add the network structure grafted carbon 1.5 bonded to PEG through the sulfonic acid group. g, stir to make the grafted carbon completely uniformly dispersed, slowly add 10M NaOH strong alkali aqueous solution dropwise until the pH value is greater than or equal to 7, then the slowly precipitated phenazine is compounded with the grafted carbon of the network structure, filtered, washed, and dried , to obtain a network structure carbon / oxazine composite material with 80% phenazine content bonded with PEG chains on the surface. Tested by the four-probe method, the electrical conductivity of the carbon / oxine composite is 6.4S cm -1 .

[0067] The carbon / oxazine composite material, conductive carbon black, and polytetrafluoroethylene (PTFE) binder were mixed in water and ...

Embodiment 3

[0069] In a reactor containing 2g of o-phenylenediamine, add 100ml of a mixed solvent of water and ethanol, heat it to 60°C under magnetic stirring to dissolve it, then add 0.5g of Ketjen black, and stir to make the grafted carbon completely uniform Disperse, slowly drop 100mL of 2M ammonium persulfate oxidant to make o-phenylenediamine oxidatively polymerized, and after 10 hours of reaction, the slowly precipitated oxine polymer and Ketjen black were compounded, filtered, washed, and dried at 80°C. Then a carbon / oxazine composite material with an oxazine polymer content of 80% is obtained. Tested by the four-probe method, the conductivity of the carbon / oxine composite is 6S cm -1 .

[0070] Mix the carbon / oxazine composite negative electrode material, conductive carbon black, and polytetrafluoroethylene (PTFE) binder in water and ethanol according to the mass ratio of 91:4:5 to make a slurry, and coat it on the foamed nickel collector. Dry at 393K in the air for 6 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com