Method for strengthening anaerobic digestion of sludge by utilizing pre-alcoholization of kitchen waste

A technology for kitchen waste and anaerobic digestion, which is applied in chemical instruments and methods, biological sludge treatment, oxidized water/sewage treatment, etc. The problems of low ethanol production efficiency, etc., achieve excellent application prospects and economic benefits, strengthen resource recovery and biogas upgrading, and achieve the effects of high methane yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

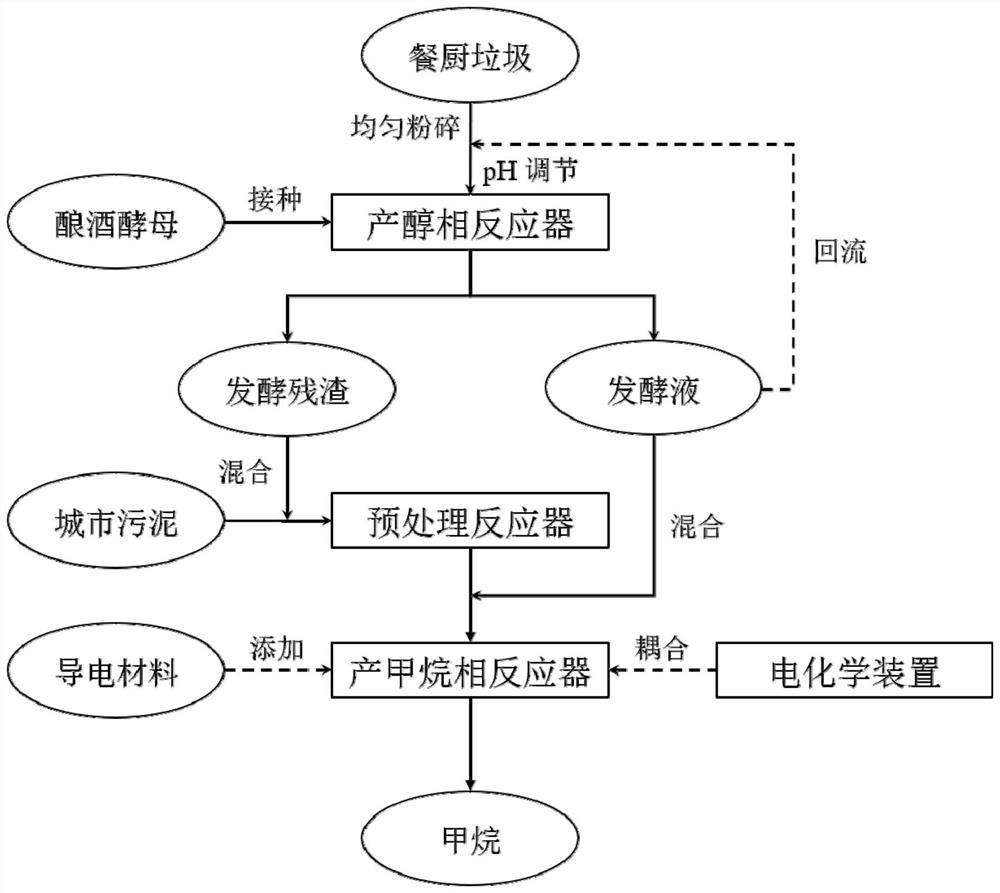

Image

Examples

Embodiment 1

[0027]This example aims to implement a method of using food waste prealcoholization to strengthen sludge anaerobic digestion in the high-solid anaerobic digestion experiment using dewatered sludge as the substrate, illustrating that the present invention can improve the organic matter degradation rate and methane production rate superior performance on.

[0028] The food waste used in the experiment comes from Xueyuan Canteen of Tongji University, and its total solid (TS) and volatile solid (VS) are 16.78% and 16.33%, respectively, VS / TS=97.32%. The sludge used was dewatered sludge from a sewage treatment plant (VS / TS=46.2-68.8%, TS=18.1-25.5%).

[0029] The food waste is evenly crushed and then enters the alcohol-producing phase reactor. The effective volume of the reactor is 1 L, and the alcohol-producing reaction is carried out at a temperature of 25° C. and a pH of 5.0 for 8 hours. The fermentation residue and dewatered sludge are mixed according to the VS mass ratio of 2...

Embodiment 2

[0037] This example aims to implement a method of using food waste pre-alcoholization to strengthen sludge anaerobic digestion in the low-solid anaerobic digestion experiment using excess sludge as the substrate, illustrating that the present invention can improve the enrichment of electroactive microorganisms, improve the Superior performance in anaerobic digestion efficiency.

[0038] The food waste used in the experiment came from Xiyuan Canteen of Tongji University (TS=14.33%, VS / TS=92.15%). The sludge used was thickened sludge from a sewage treatment plant (VS / TS=50.1-65.7%, TS=3.9-5.6%).

[0039] The food waste is evenly crushed and enters the alcohol-producing phase reactor with an effective volume of 0.5 L. The alcohol-producing reaction is carried out at a temperature of 30° C. and a pH of 4.5 for 4 hours. Fermentation residue and dewatered sludge are mixed according to the VS mass ratio of 1:1 and then enter the pretreatment reactor. Ultrasonic (frequency 24kHz, pow...

Embodiment 3

[0047] This example aims to implement a method of using food waste pre-alcoholization to strengthen sludge anaerobic digestion in the high-solid anaerobic digestion experiment using mixed sludge as the substrate, illustrating that the present invention strengthens sludge anaerobic digestion to produce methane, Improve the superior performance of methane in the proportion of biogas.

[0048] The food waste used in the experiment came from Nanyuan Canteen of Tongji University (TS=13.71%, VS / TS=82.99%). What used for the sludge was the mixed sludge (VS / TS=47.7-62.1%, TS=17.3-25.2%) of the secondary sedimentation tank sludge and the dewatered sludge of the sewage treatment plant.

[0049] The food waste is evenly crushed and then enters the alcohol-producing phase reactor. The effective volume of the reactor is 4L, and the alcohol-producing reaction is carried out at a temperature of 23°C and a pH of 4.3 for 10 hours. Fermentation residue and mixed sludge are mixed according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com