Packaging method of metal lithium reference electrode for lithium battery

A packaging method and reference electrode technology, which are applied in battery electrodes, non-aqueous electrolyte battery electrodes, lithium batteries, etc., can solve the problems of complex operation, inability to balance effectiveness and practicability, and high cost, and achieve simple process and improved Practicality and service life, the effect of improving the level of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

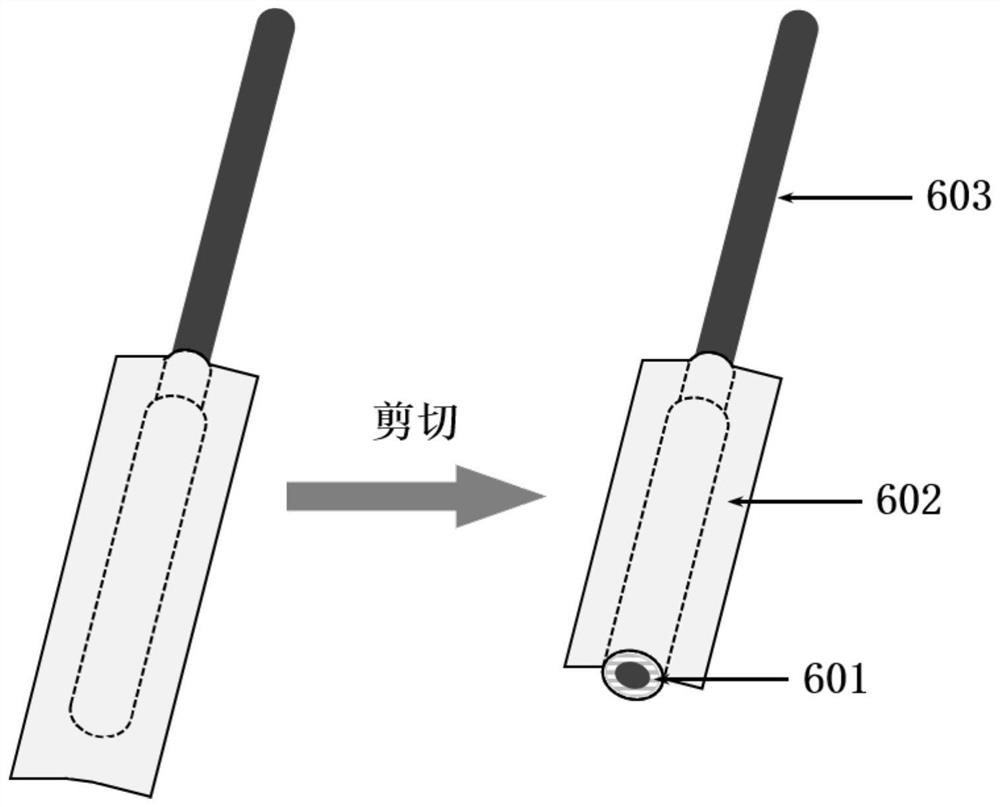

[0032] 1) Preparation of reference electrode: In a dry room environment, use a roller press to roll 5 μm ultra-thin lithium foil onto clean copper foil on both sides, and then cut it into strips of 0.1×8cm in size;

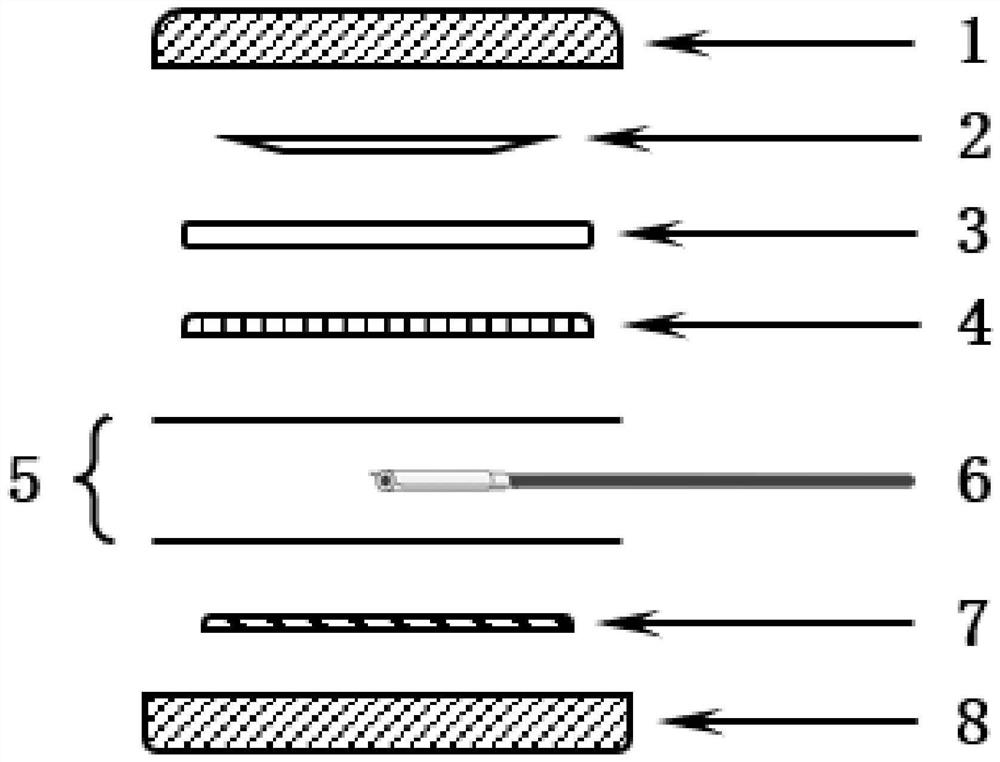

[0033] 2) Encapsulation of the reference electrode: use polyethylene terephthalate with a total thickness of about 18 μm, the first polymer layer is 12 μm thick, the second metal aluminum layer is an aluminum layer of 0.3 μm, and the third polymer layer is The material of the object layer is aluminum-coated composite film of 6 μm thick polyethylene, after covering the electrode, the reference electrode is packaged by hot pressing, and then the excess part is cut;

[0034] 3) Press figure 2 Assembled three-electrode full cell shown:

[0035] When the reference electrode 6 is assembled, the tip is cut off to expose an active material with a size of 1×0.01mm, and it is placed between the positive and negative electrodes at the center, and separated from the positiv...

Embodiment 2

[0041] 1) Preparation of the reference electrode: use a paint remover to remove the paint from both ends of the enamelled aluminum wire with a diameter of 130 μm, ultrasonically clean it with anhydrous ethanol and then dry it, then wrap a 33 μm ultra-thin lithium ribbon on the depainted end of the aluminum wire ;

[0042] 2) Encapsulation of the reference electrode: use polytetrafluoroethylene with a total thickness of about 1 μm, the first polymer layer is 0.6 μm thick, the second metal aluminum layer is an aluminum layer of 0.3 μm, and the third polymer layer is made of After the electrode is covered with aluminized film of 0.1μm thick polypropylene, the reference electrode is packaged by hot pressing, and then the excess part is cut;

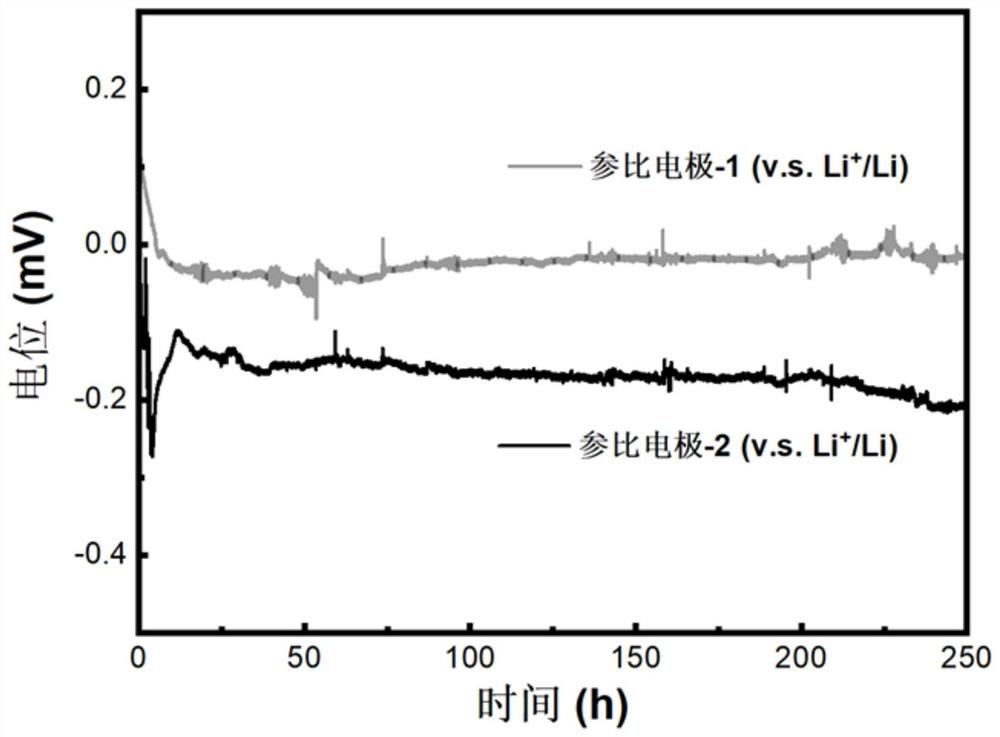

[0043] 3) Three-electrode full battery assembly: the negative electrode uses a 50 μm double-sided roll-pressed 4×7 cm lithium metal sheet on the copper grid; the positive electrode uses commercial double-sided LiNi 0.8 co 0.1 mn 0.1 o 2 (...

Embodiment 3

[0047] 1) Preparation of reference electrode: Place one end of a 4×7cm clean nickel mesh in 0.1mol / L silver nitrate solution for 2 seconds, so that the surface of the nickel mesh is evenly covered with metallic silver particles, and after drying, place the end of the clean nickel mesh under an argon atmosphere. Immerse in molten lithium at 200°C, take out and coat the surface of the nickel mesh with a layer of metal lithium after cooling;

[0048] 2) Encapsulation of the reference electrode: use polyamide with a total thickness of 100 μm, 30 μm thick polyamide for the first polymer layer, 40 μm aluminum metal foil for the second metal aluminum layer, and 30 μm thick ethylene-acrylic acid for the third polymer layer material After the electrode is covered with the aluminum-plastic film of the copolymer, the reference electrode is packaged by hot pressing, and then the excess part is cut;

[0049] 3) Three-electrode full battery assembly: the negative electrode uses a 50 μm doub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com