Preparation method and application of silver-copper bimetal nanofibers

A technology of bimetallic nano and copper nanofibers, applied in metal processing equipment, nanotechnology, conductive layers on insulating carriers, etc., can solve problems such as moiré, high cost, and limitations, achieve high aspect ratio and improve purity , the effect of increasing the density of crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

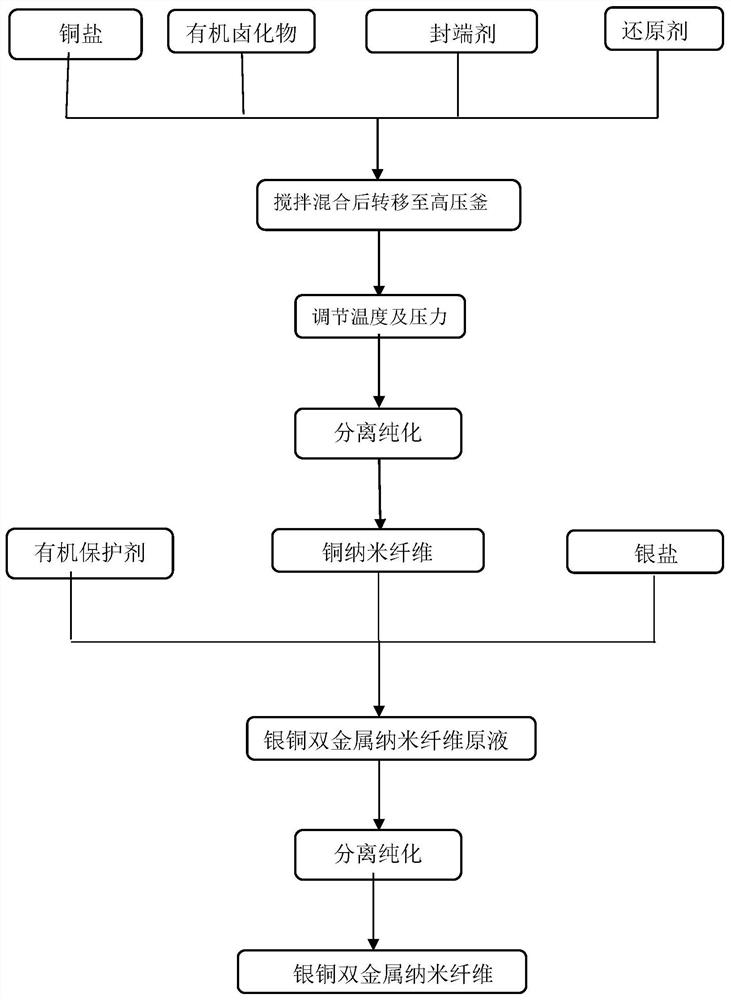

[0072] The embodiment of the present invention discloses a method for preparing silver-copper bimetallic nanofibers, comprising the following steps:

[0073] (1) Mix and stir the copper salt solution, the organic halide solution, the capping agent solution and the reducing agent solution evenly to obtain solution A;

[0074] (2) Transfer the solution A to a high-pressure reactor and raise the temperature to 80° C. to 300° C. for 20-1440 minutes to obtain a copper nanofiber stock solution;

[0075] (3) Separating and purifying the copper nanofiber stock solution to obtain copper nanofibers;

[0076] (4) After adding an organic protective agent solution and a silver salt solution to the copper nanofiber aqueous solution, mix and stir evenly to obtain a solution B;

[0077] (5) Transfer the solution B to a three-necked flask, and stir for 10-360min under the protection of an inert gas to obtain a stock solution of silver-copper bimetallic nanofibers;

[0078] (6) After the silv...

Embodiment 1

[0098] A preparation method of silver-copper bimetallic nanofibers, specifically as follows:

[0099] (1) 0.398g copper acetate, 0.448g 6-bromohexyltrimethylammonium bromide, 3.01g cetyltrimethylammonium hydroxide, 2.056g tetrabutylammonium borohydride, 0.25g polyvinylpyrrolidone- Polyethylene glycol diblock copolymer (molecular weight M w =100000) and 0.26g of silver acetate were dissolved in water of 80mL, 100mL, 70mL, 100mL, 50mL, and 50mL respectively to form an aqueous solution for subsequent use;

[0100] (2) Put copper acetate solution, 6-bromohexyltrimethylammonium bromide solution, hexadecyltrimethylammonium hydroxide solution and tetrabutylammonium borohydride solution at 15°C with a stirring speed of 10r / s Down mixing 30min, obtains reaction solution A;

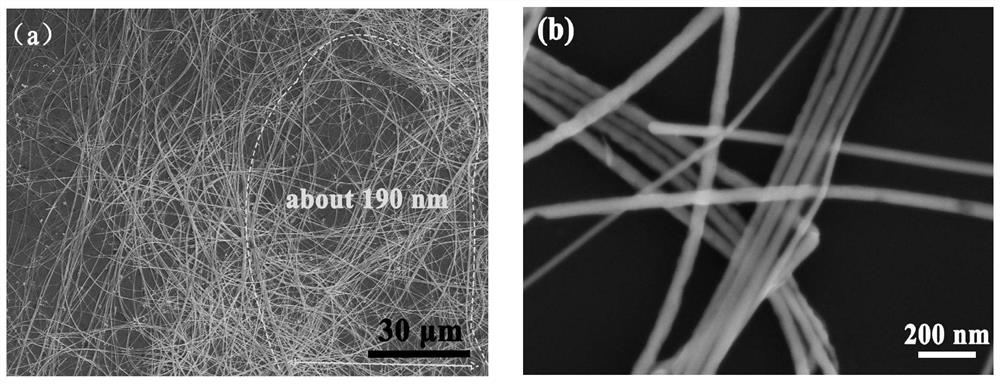

[0101] (3) Transfer the reaction solution A to a 500mL high-pressure reactor, raise the temperature to 210°C at a rate of 1°C / min, and fill it with high-purity argon to pressurize to 0.2MPa, and then maintain the...

Embodiment 2

[0107] A preparation method of silver-copper bimetallic nanofibers, specifically as follows:

[0108] (1) 0.235g copper acetate, 0.126g copper acetylacetonate, 0.537g tetrapropylammonium bromide, 5.27g dipalmitoylphosphatidylcholine, 2.056g tetrabutylammonium borohydride, 1.47g polyvinylpyrrolidone-poly Ethylene glycol diblock copolymer (molecular weight M w =500000) and 0.5g of silver nitrate were dissolved in water of 60mL, 40mL, 90mL, 60mL, 80mL, 20mL, and 10mL respectively to form an aqueous solution for subsequent use;

[0109] (2) Mix copper acetate solution, copper acetylacetonate solution, tetrapropylammonium bromide solution, dipalmitoylphosphatidylcholine solution, and tetrabutylammonium borohydride solution at 10°C for 5 minutes at a stirring speed of 15r / s , to obtain the reaction solution A;

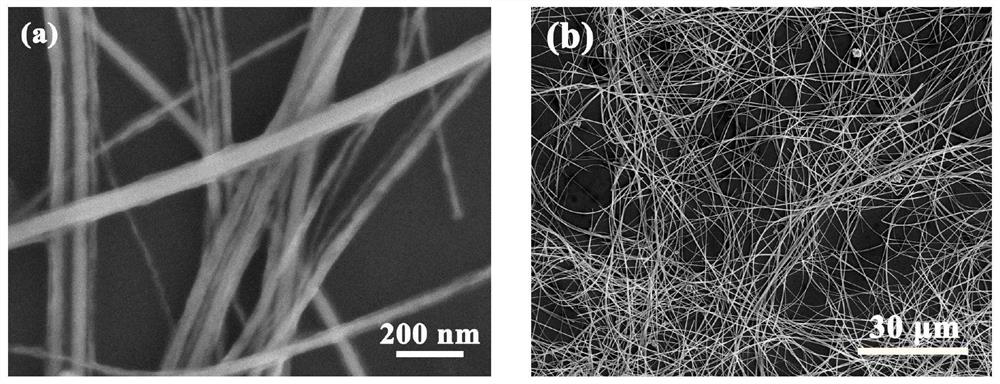

[0110] (3) Transfer the reaction solution A into a 400mL autoclave, raise the temperature to 130°C at a rate of 2.5°C / min, fill it with high-purity argon and pressurize it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com