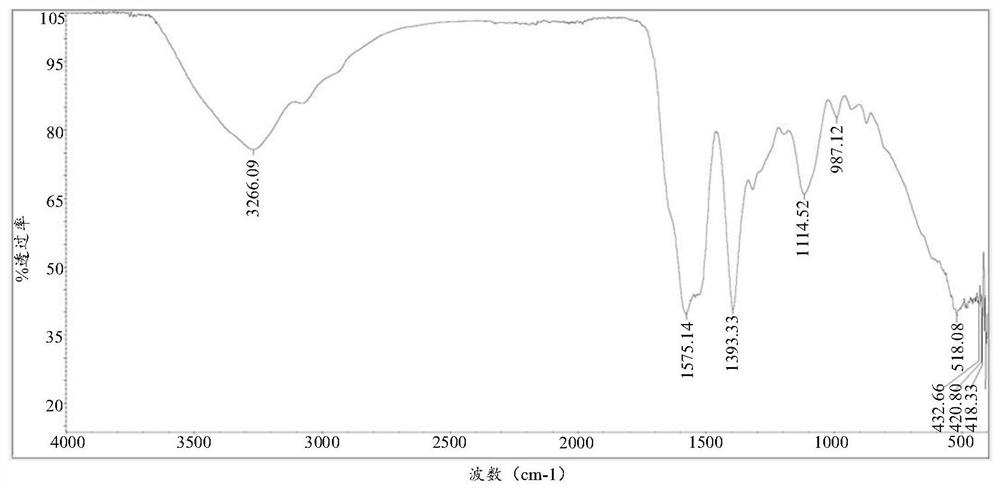

Preparation method of polysuccinimide and polyaspartic acid

A technology of polysuccinimide and polysuccinic acid imide, which is applied in the field of chemical synthesis, can solve problems affecting product content and performance, low recycling rate, and complicated recycling, so as to achieve good product performance and high product quality , the effect of thorough response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

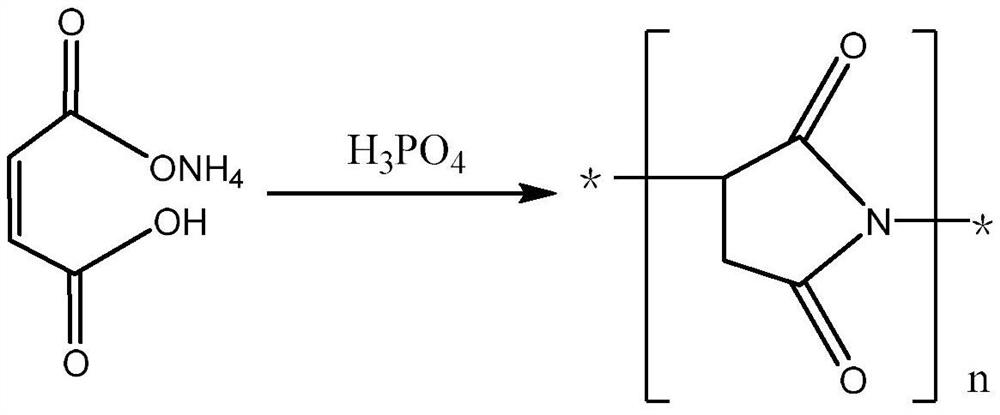

[0032] The present application provides the first preparation method of polysuccinimide, and the preparation method includes the following steps.

[0033] Step 11: Providing the ammonium maleate salt.

[0034] Ammonium maleate can be provided first to prepare polysuccinimide through ammonium maleate.

[0035] Alternatively, the ammonium maleate finished product can be provided directly.

[0036] Of course, you can also make your own ammonium maleate. Specifically, ammonium maleate can be prepared by various methods.

[0037] For example, ammonium maleate can be obtained by reacting fumaric acid with an ammonia-containing compound. Alternatively, the nitrogen-containing compound and fumaric acid may be reacted for a first time at a second temperature to obtain the ammonium maleate salt. Wherein, the second temperature may be 70-100°C, such as 75°C, 80°C, 85°C, 90°C, etc. The first time may be 1-5h, such as 2h, 3h, 4h and so on.

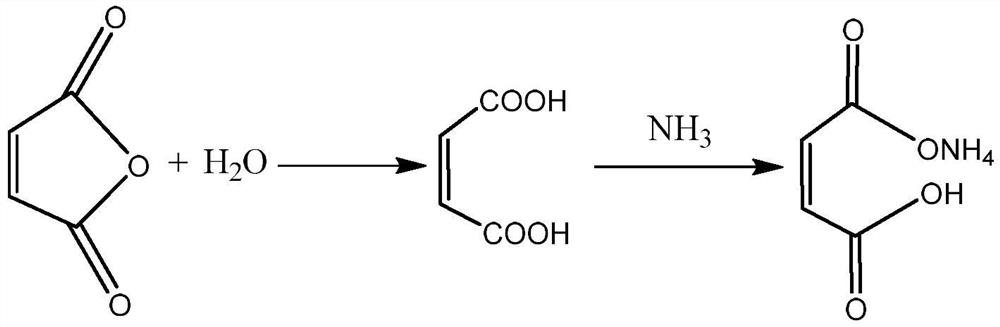

[0038] For another example, maleic acid an...

Embodiment 1

[0086] (1) Preparation of polysuccinimide

[0087] Add 196g of maleic anhydride to a 2000mL four-necked bottle, then add 200g of deionized water, stir and heat up to 60°C for hydrolysis. Then, 85 g of 28% (mass fraction) ammonia water was slowly added dropwise to the hydrolyzed solution. After the dropwise addition, the solution was warmed up to 85° C. and aged for 3 hours to obtain an ammonium maleate solution. Add 200g of methyl silicone oil with a viscosity of 100CS into the reaction kettle, increase the temperature of the methyl silicone oil in the reaction kettle to 180-190°C, and then slowly add the maleamide salt solution into the methyl silicone oil dropwise. edge access N 2 After the dropwise addition was completed, the reaction was incubated for 2 hours, and then the temperature was lowered to room temperature to obtain a heat transfer oil solution containing polysuccinimide.

[0088] (2) Preparation of polyaspartic acid

[0089] Add the prepared liquid caustic so...

Embodiment 2

[0091](1) Preparation of polysuccinimide

[0092] Add 196g of maleic anhydride to a 2000mL four-necked bottle, then add 200g of deionized water, stir and heat up to 60°C for hydrolysis. Then, 85 g of 28% (mass fraction) ammonia water was slowly added dropwise to the hydrolyzed solution. After the dropwise addition, the solution was warmed up to 85° C. and aged for 3 hours to obtain an ammonium maleate solution. Add 200g of simethicone oil with a viscosity of 100CS into the reactor, increase the temperature of the simethicone in the reactor to 180-190°C, then slowly add the maleamide salt solution into the simethicone, Inject N while dropping 2 After the dropwise addition was completed, the reaction was incubated for 2 hours, and then the temperature was lowered to room temperature to obtain a heat transfer oil solution containing polysuccinimide.

[0093] (2) Preparation of polyaspartic acid

[0094] Add the prepared liquid caustic soda to the heat-conducting oil solution c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com