Preparation method, product and application of zinc oxide modified gallium nitride silver-loaded nanorod heterojunction photocatalyst

A zinc oxide modification, photocatalyst technology, applied in the field of photocatalysis, can solve the problems of reducing the redox ability of valence band holes and conduction band electrons, reducing the band gap, increasing the absorption of visible light, etc., and achieving the effect of excellent catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

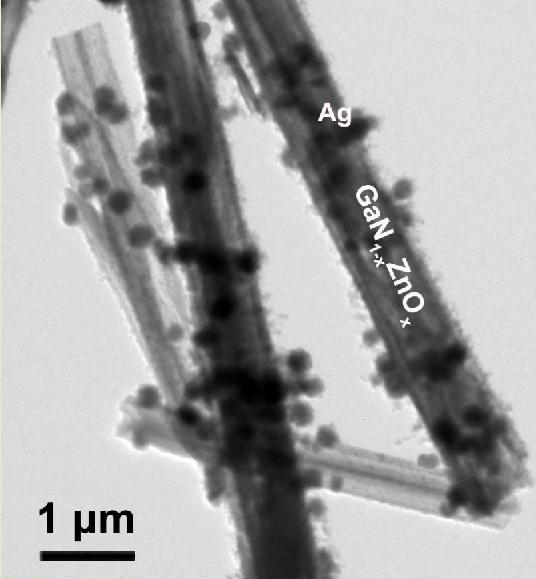

[0027] A silver-supported nanorod heterojunction photocatalyst of zinc oxide-modified gallium nitride prepared by sol-gel method (GaN) 1-x (ZnO) x Solid solution gel, spin-coated on the surface of Si wafers grown on the (100) crystal plane, and obtained after ammonia treatment (GaN) 1-x (ZnO) x solid solution nanorods, followed by photodeposition to carry Ag modification, to obtain Ag / (GaN) 1-x(ZnO) x The nanorod material is prepared as follows:

[0028] a. One-dimensional (GaN) 1-x (ZnO) x Preparation of solid solution nanorods: First, weigh 6.71g of gallium nitrate hydrate and 2.47g of zinc acetate dihydrate and dissolve them in 2.3 mL of ethylenediamine and 50 mL of ethylene glycol in methyl ether, and stir for 60 minutes in a water bath at 70°C , to form a transparent gel solution; then, the sol was spin-coated on a (100) oriented Si sheet at a speed of 800 rpm, and dried at 200°C for 15 min to form a gel; then, placed in a tube furnace for 800 Calcined at ℃ for 60 ...

Embodiment 2

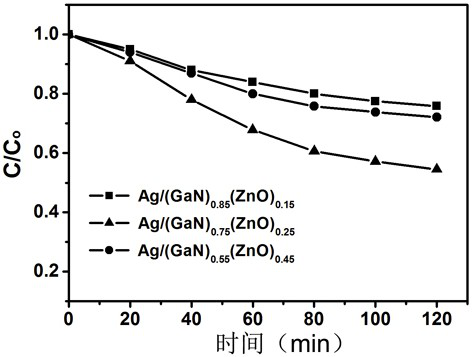

[0033] A silver-loaded nanorod heterojunction photocatalyst of zinc oxide modified gallium nitride, similar to Example 1, according to the following steps:

[0034] a. One-dimensional (GaN) 1-x (ZnO) x Preparation of solid solution nanorods: First, weigh 6.71g of gallium nitrate hydrate and 2.47g of zinc acetate dihydrate and dissolve them in 2.3 mL of ethylenediamine and 50 mL of ethylene glycol in methyl ether, and stir for 60 minutes in a water bath at 70°C , to form a transparent gel solution; then, the sol was spin-coated on a (100)-oriented Si sheet at a speed of 800 rpm, and dried at 200°C for 15 min to form a gel; then, placed in a tube furnace for 700 Calcined at ℃ for 60 min to obtain a white and uniform Zn-Ga-O precursor film; finally, the obtained Zn-Ga-O film was moved into a chemical vapor deposition CVD furnace, and ammonia gas was introduced at a temperature of 800~1000℃ Nitriding for 2h, one-dimensional (GaN) 0.85 (ZnO) 0.15 Solid solution nanorod material...

Embodiment 3

[0038] A silver-loaded nanorod heterojunction photocatalyst of zinc oxide modified gallium nitride, similar to Example 1, according to the following steps:

[0039] a. One-dimensional (GaN) 1-x (ZnO) x Preparation of solid solution nanorods: First, weigh 6.71g of gallium nitrate hydrate and 2.47g of zinc acetate dihydrate and dissolve them in 2.3 mL of ethylenediamine and 50 mL of ethylene glycol in methyl ether, and stir for 60 minutes in a water bath at 70°C , to form a transparent gel solution; then, the sol was spin-coated on a (100)-oriented Si sheet at a speed of 800 rpm, and dried at 200°C for 15 min to form a gel; then, placed in a tube furnace for 900 Calcined at ℃ for 60 min to obtain a white and uniform Zn-Ga-O precursor film; finally, the obtained Zn-Ga-O film was moved into a chemical vapor deposition CVD furnace, fed with ammonia gas and nitrided at 1000℃ 2h, that is, one-dimensional (GaN) 0.55 (ZnO) 0.45 solid solution nanorods;

[0040] b. Photodeposited A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com