Preparation process suitable for superconducting detector glass window

A technology of superconducting detector and preparation process, applied in the field of superconducting electronics, can solve the problems of detector pattern damage, extremely thin glass window being fragile, unable to withstand high back helium gas pressure, etc., to reduce noise and improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034]A preparation process suitable for glass windows of superconducting detectors includes the following steps:

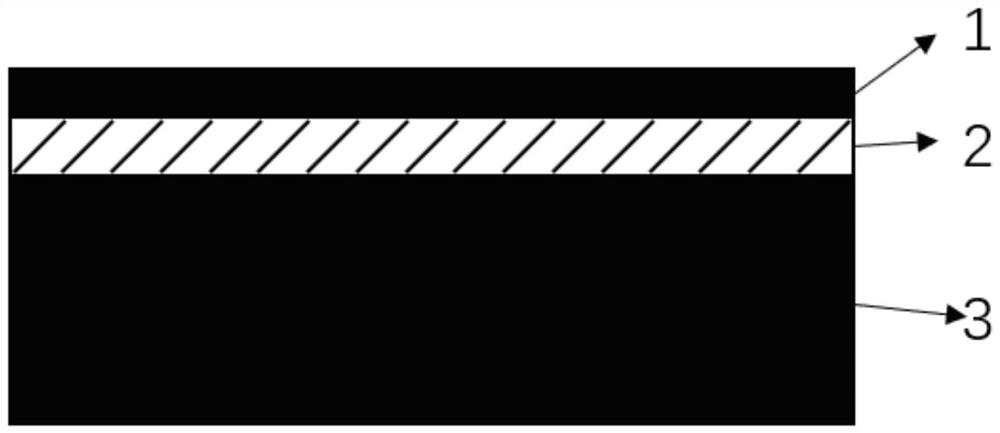

[0035]Step 1: Prepare a glass window wafer, which in turn includes a glass window layer 1, a silicon dioxide stop layer 2 and a silicon layer 3 made of silicon or silicon nitride, such asfigure 1 Shown

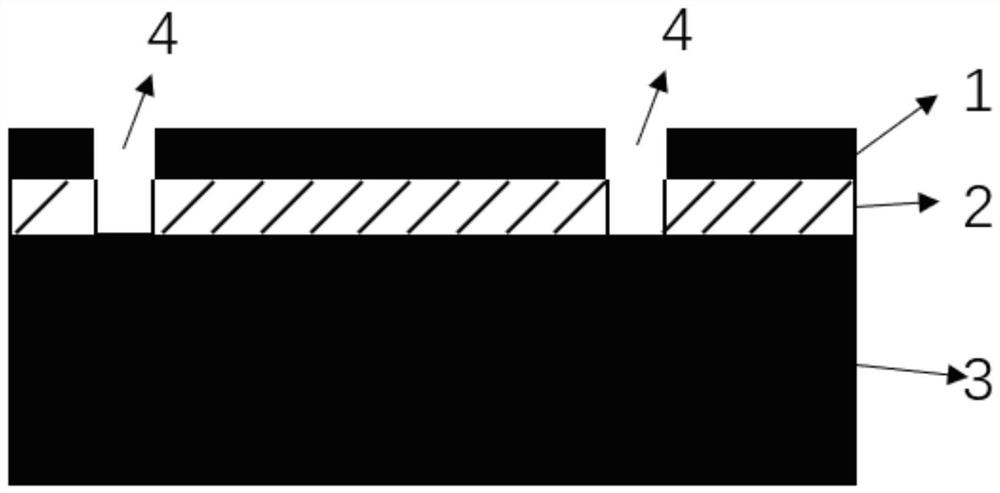

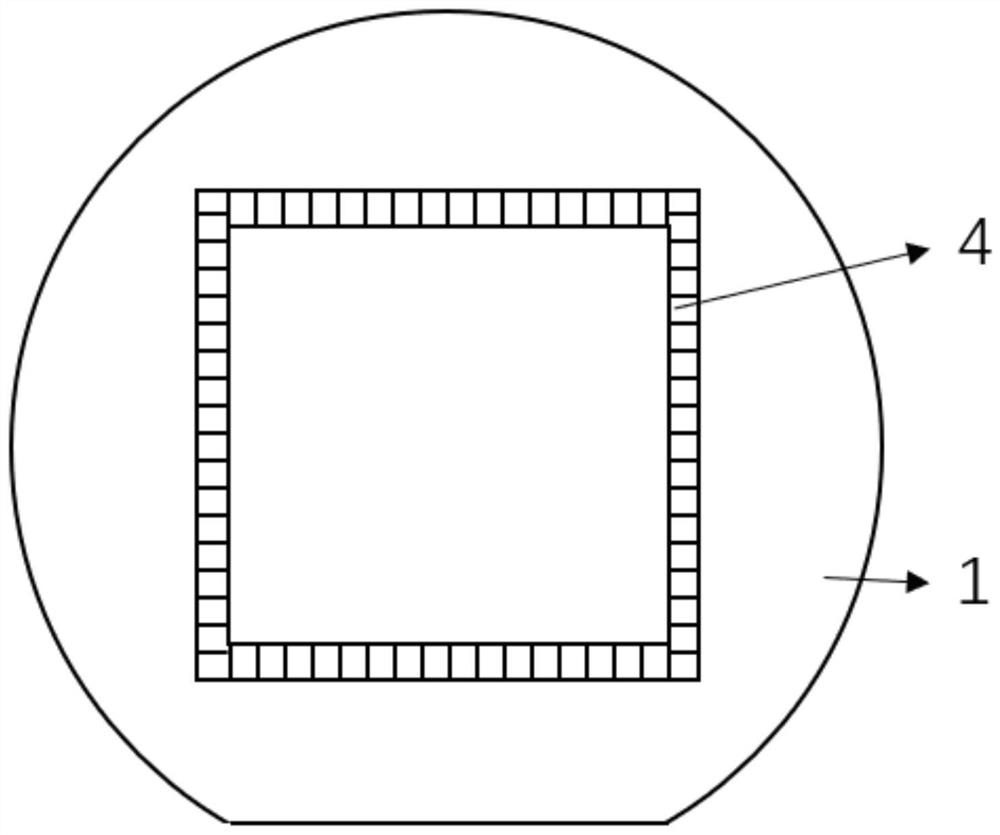

[0036]Step 2: Use a photolithography process to prepare the chip boundary cutting groove pattern on the glass window layer 1, and use a fluorine-based gas to etch the chip boundary cutting groove 4 until the silicon or silicon nitride in the chip boundary cutting groove 4 and the second The silicon oxide stop layer is completely etched, such asfigure 2 ,3Shown

[0037]Step 3: Use the organic solvent acetone to dissolve the paraffin to prepare an adhesive; bond the glass window layer 1 side of the glass window wafer to a piece of carrier wafer 5 with the prepared adhesive, such asFigure 4 As shown; when the glass window layer 1 and the carrier wafer 5 are bonded, it must be ensu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com