Antibacterial and anti-ultraviolet color temperature regulating coating containing iron oxide/silicon dioxide coated paraffin phase-change microcapsules and preparation method thereof

A technology of phase change microcapsules and paraffin microcapsules, which is applied in the field of coatings, can solve the problems of easy agglomeration, uneven distribution of coating colors, poor dispersion, etc., and achieve the effect of high bonding fastness and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

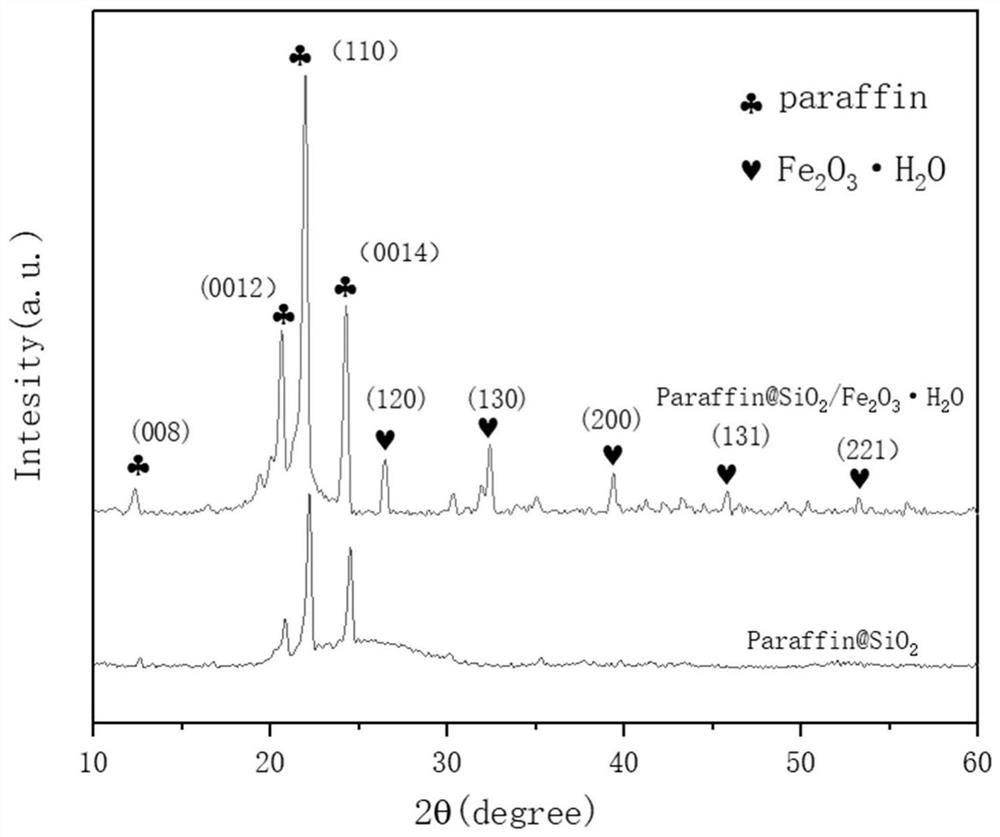

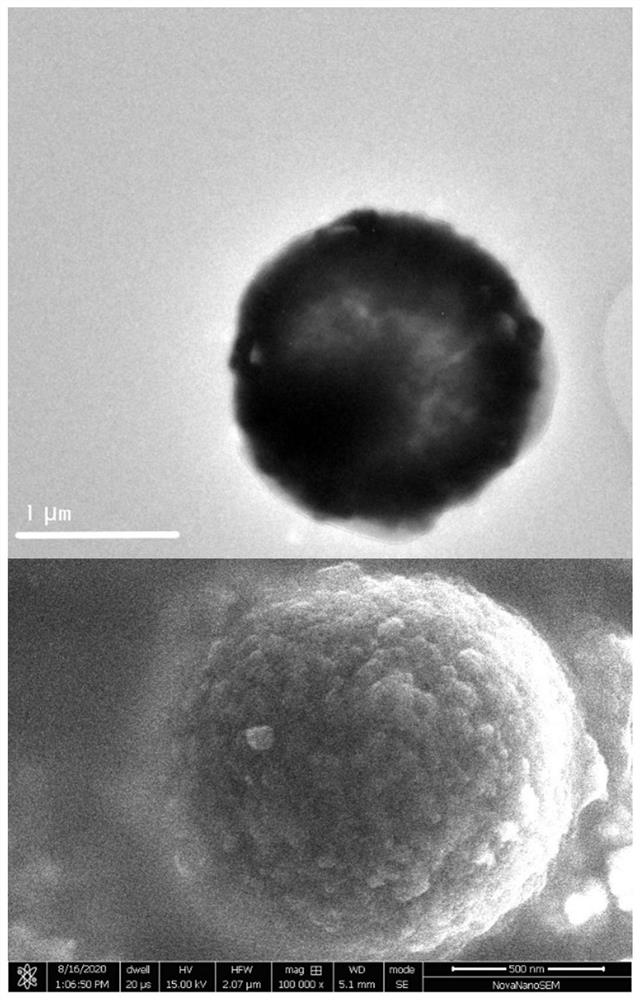

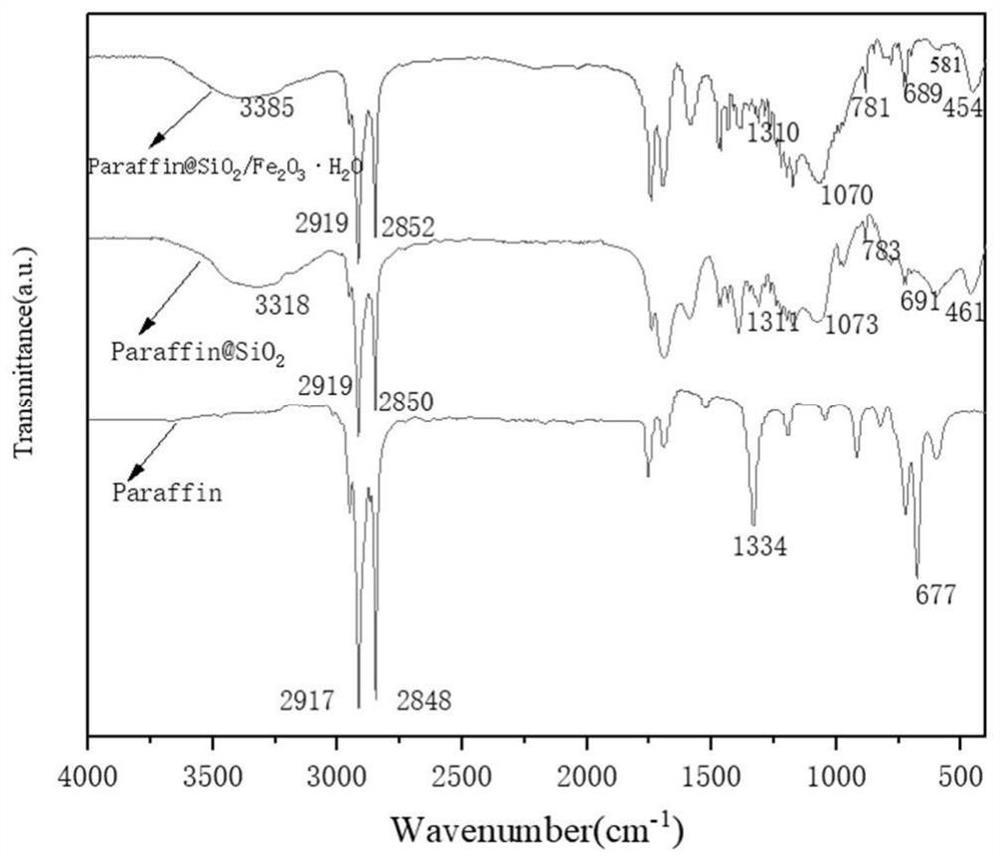

Embodiment 1

[0060] (1) Add 7.5g of paraffin and 7.5g of tetraethyl orthosilicate solution into a three-necked flask and mix them, mechanically stir for 30min at 50°C, add 1.13g of CTAB (hexadecyltrimethylbromide) dissolved in 100mL of formamide solution Ammonium chloride) solution, reacted at 1500rpm for 4h to obtain a uniform dispersed emulsion.

[0061] (2) Adjust the rotational speed to 700 rpm, take 100 mL of 1 mol / L HCl solution, add it dropwise into a three-necked flask at 2 drops / s, and react for 4 hours to obtain a white precipitate.

[0062] (3) Stop stirring, keep the temperature at 50°C, mature for 18h, pour it out, centrifuge, wash with n-hexane three times, and dry the product in an 80°C drying oven to obtain Paraffin@SiO 2 .

[0063] (4) Take 1.5g Paraffin@SiO 2 Place in a beaker, add 100mL of distilled water, and ultrasonically disperse at 80°C for 45min to obtain a uniformly dispersed solution.

[0064] (5) Transfer the solution in the beaker to a three-necked flask, ad...

Embodiment 2

[0069] (1) Add 7.0g of paraffin and 8.0g of tetraethyl orthosilicate solution into a three-necked flask and mix them, mechanically stir for 35min at 45°C, add 1.1g of CTAB (hexadecyltrimethyl bromide) dissolved in 120mL of formamide solution Ammonium chloride) solution, reacted at 1200rpm for 5h to obtain a uniform dispersed emulsion.

[0070] (2) Adjust the rotational speed to 500 rpm, take 100 mL of 0.8 mol / L HCl solution, add it dropwise into a three-necked flask at 1.5 drops / s, and react for 5 hours to obtain a white precipitate.

[0071] (3) Stop stirring, keep the temperature at 45°C, mature for 20h, pour it out, centrifuge, wash with n-hexane three times, and dry the product in a 75°C drying oven to obtain Paraffin@SiO 2 .

[0072] (4) Take 1.3g Paraffin@SiO 2 Place in a beaker, add 100mL of distilled water, and ultrasonically disperse at 75°C for 50min to obtain a uniformly dispersed solution.

[0073] (5) Transfer the solution in the beaker to a three-necked flask,...

Embodiment 3

[0078] (1) Put 8.0g of paraffin and 7.0g of tetraethyl orthosilicate solution into a three-necked flask and mix them, mechanically stir at 55°C for 25min, add 1.2g of CTAB (hexadecyltrimethyl bromide) dissolved in 120mL of formamide solution Ammonium chloride) solution, reacted at 1400rpm for 3h to obtain a uniform dispersed emulsion.

[0079] (2) Adjust the rotational speed to 600 rpm, take 100 mL of 1.2 mol / L HCl solution, add it dropwise into a three-necked flask at 2.5 drops / s, and react for 3 hours to obtain a white precipitate.

[0080] (3) Stop stirring, keep the temperature at 55°C, mature for 5h, pour it out, centrifuge, wash with n-hexane three times, and then dry the product in a drying oven at 85°C to obtain Paraffin@SiO 2 .

[0081] (4) Take 1.7g Paraffin@SiO 2 Place in a beaker, add 100mL of distilled water, and ultrasonically disperse at 85°C for 40min to obtain a uniformly dispersed solution.

[0082] (5) Transfer the solution in the beaker to a three-necked...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com