Method for separating and recovering valuable metals in cyanide-containing wastewater

A valuable metal, separation and recovery technology, applied in the direction of metal cyanide, ferricyanide, copper oxide/copper hydroxide, etc., can solve the problems of low filtration efficiency, high moisture content of filter cake, difficult solid-liquid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

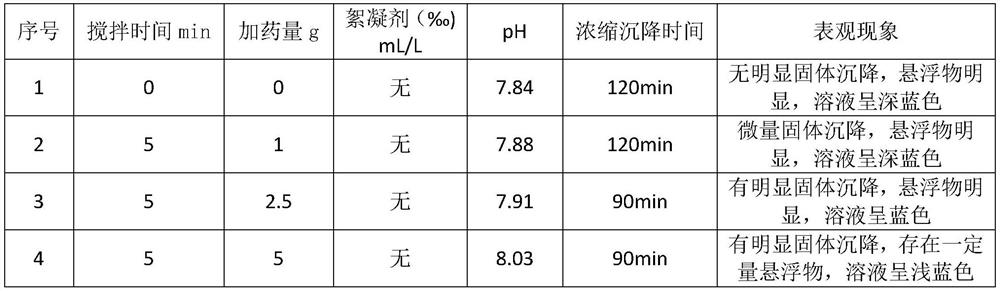

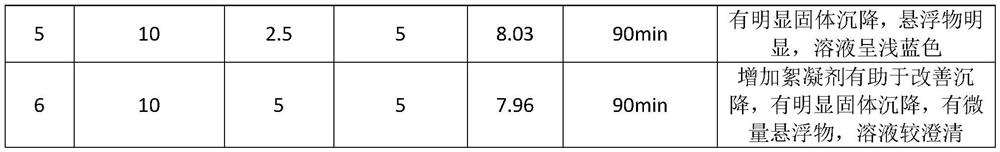

[0041] Cyanide-containing barren solution of a gold mine, pH value is 10.3-10.8, CN T 1689.22mg / L, CN f It is 379.89mg / L, Cu is 223mg / L, Fe is 675mg / L, and it also contains other heavy metal ions. Take the waste water and put it in the stirring tank, add concentrated sulfuric acid to adjust the pH of the poor solution to about 9, add 6mL / L hydrogen peroxide (30%) and stir for 1 hour, then pump the solution into the deep cone thickener, The enrichment and concentration of copper-containing precipitates is completed under the action of sedimentation, and the concentrated underflow is separated by a horizontal screw discharge sedimentation centrifuge. The separation factor reaches 2500G to realize the forced enrichment and solidification separation of the flocculent solid.

[0042] Take filtrate analysis: CN T 1110.6mg / L, CN f is 36.3mg / L, Cu is 18.7mg / L, and Fe is 585.6mg / L. Get 6 parts of 1L filtrate, add 4g / L ferrous sulfate (FeSO 4 ·7H 2 0) after stirring and reacting f...

Embodiment 2

[0052] Cyanide-containing wastewater from a gold mine, with a pH value of 12.89, CN T 7156mg / L, CN f It is 3710mg / L, Cu is 2046mg / L, Fe is 2083mg / L, and there are other heavy metal ions. Take 2L of waste water and place it in a stirring tank, add concentrated sulfuric acid to adjust the pH of the poor solution to about 9, add 18mL / L hydrogen peroxide (30%) and stir for 1 hour, then pump the solution into a deep cone thickener, The enrichment and concentration of copper-containing precipitates is completed under the action of flocculation and sedimentation. The concentrated underflow is separated by a strong field high-speed centrifuge—horizontal screw discharge sedimentation centrifuge. The separation factor reaches 2500G to realize the forced enrichment and solidification of the flocculent solid Separation, filtrate analysis: CN T 3253.9mg / L, CN f 185.4mg / L, Cu 122.6mg / L, and Fe 1241.5mg / L. Take 1.5L filtrate, add 9g / L ferrous sulfate (FeSO 4 ·7H 2 O) After stirring for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com