A method for preparing air-entrained concrete using recycled concrete aggregates and air-entrained concrete

A technology of recycled concrete and air-entrained concrete, which is applied in the field of building materials, can solve the problems affecting the anti-crack performance of recycled air-entrained concrete blocks and the increase of porosity, so as to reduce the environmental burden, improve the bonding strength, and improve the compression resistance intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: a kind of method utilizing recycled concrete aggregate to prepare air-entrained concrete comprises the steps:

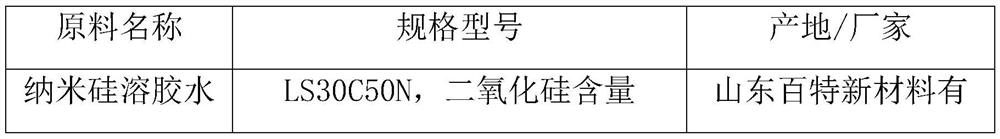

[0041] S1 Recycled aggregate pretreatment: Take recycled concrete powder, sieve it with a sieve with a pore size of 500 μm, and select recycled concrete powder with a particle size not greater than 500 μm. Take by weighing 45kg nano-silica sol aqueous solution (model is LS30C50N, silicon dioxide content 50%, median particle size 30nm), add 40kg water and 10kg hydroxypropyl distarch phosphate, add 105kg regenerated concrete powder, with 200 rpm Stir at a rotating speed for 20 minutes, transfer the material to a ball mill, track the particle size of the material with a sieve with a pore size of 300 μm, and ball mill the material until the particle size is not greater than 300 μm, heat the material to 45°C and stir for 20 minutes, stop stirring, and then put the material at 80 Dry at ℃ for 150min to obtain recycled aggregate.

[0042] S2 Slurry pre...

Embodiment 2

[0046] The difference between embodiment 2 and embodiment 1 is that the specifications and models of nano-neutral silica sol used in embodiment 2 and embodiment 1 are different (provided by Shandong Baite New Material Co., Ltd., the model is LS50C30N, and the mass content of silicon dioxide is 30 %, median diameter 50nm), others are consistent with Example 1.

Embodiment 3

[0048] The difference between Example 3 and Example 1 is that step S1 of Example 3 does not ball mill the regenerated aggregate with a ball mill, and the others are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com