Method for efficiently degrading indoor formaldehyde

A formaldehyde and high-efficiency technology, applied in the field of high-efficiency degradation of indoor formaldehyde, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

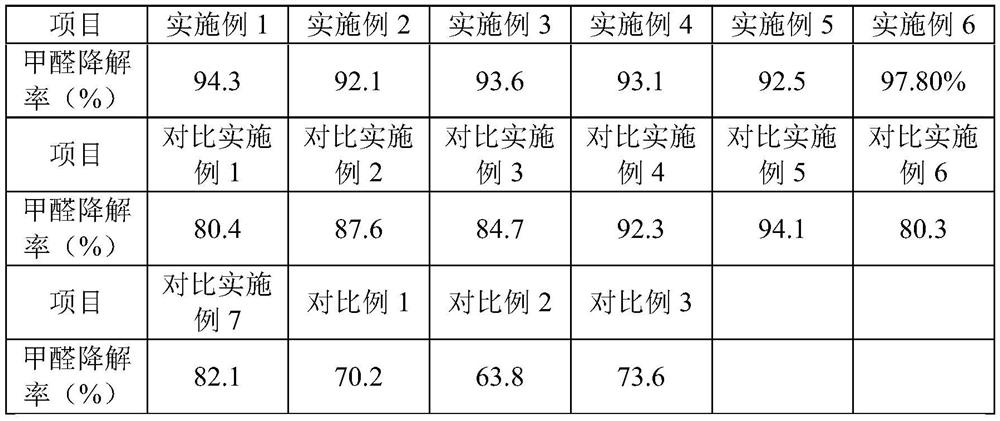

Examples

Embodiment 1

[0045] This embodiment provides a method for efficiently degrading indoor formaldehyde, comprising the following steps:

[0046] S1, configure solid medium A, its formula is: beef extract 3g / L, peptone 10g / L, sodium chloride 5g / L, potassium dihydrogen phosphate 0.6g / L, dipotassium hydrogen phosphate 0.85g / L, agar 20g / L, and trace element solution 550μL / L. The trace element solution is prepared by dissolving the following raw materials in deionized water: boric acid 6g / L, copper chloride 0.2g / L, cobalt chloride 4g / L, nickel chloride 0.4g / L, zinc sulfate 2g / L, chlorine Manganese chloride 0.6g / L.

[0047] Configure solid LB medium, its formula is: tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, agar 20g / L.

[0048] Configure solid medium B, its formula is: sodium malate 1.0g / L, sodium acetate 1.0g / L, ammonium chloride 1.0g / L, potassium dihydrogen phosphate 1.0g / L, calcium chloride 0.1g / L, Sodium bicarbonate 2.9g / L, magnesium chloride 0.4g / L, trace element solution ...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that some process parameters are different in the method of this embodiment, specifically: a method for efficiently degrading indoor formaldehyde, comprising the following steps:

[0059] S1. Configure solid medium A, its formula is: beef extract 2.5g / L, peptone 9g / L, sodium chloride 4g / L, potassium dihydrogen phosphate 0.5g / L, dipotassium hydrogen phosphate 0.7g / L, agar 18g / L, and trace element solution 500μL / L. The trace element solution is prepared by dissolving the following raw materials in deionized water: boric acid 5g / L, copper chloride 0.1g / L, cobalt chloride 3g / L, nickel chloride 0.3g / L, zinc sulfate 1.5g / L, Manganese chloride 0.4g / L.

[0060] Configure solid LB culture medium, its formula is the same as embodiment 1.

[0061] Configure solid medium B, its formula is: sodium malate 0.8g / L, sodium acetate 0.8g / L, ammonium chloride 0.8g / L, potassium dihydrogen phosphate 0.8g / L, calcium chloride 0.08g / L...

Embodiment 3

[0071] The difference between this embodiment and Embodiment 1 is that some process parameters are different in the method of this embodiment, specifically: a method for efficiently degrading indoor formaldehyde, comprising the following steps:

[0072] S1, configure solid medium A, its formula is: beef extract 3.5g / L, peptone 12g / L, sodium chloride 6.5g / L, potassium dihydrogen phosphate 0.7g / L, dipotassium hydrogen phosphate 0.85g / L, Agar 22g / L, and trace element solution 600μL / L. The trace element solution is prepared by dissolving the following raw materials in deionized water: boric acid 7g / L, copper chloride 0.3g / L, cobalt chloride 5g / L, nickel chloride 0.5g / L, zinc sulfate 2.5g / L, Manganese chloride 0.8g / L.

[0073] Configure solid LB culture medium, its formula is the same as embodiment 1.

[0074] Configure solid medium B, its formula is: sodium malate 1.3g / L, sodium acetate 1.3g / L, ammonium chloride 1.3g / L, potassium dihydrogen phosphate 1.3g / L, calcium chloride 0.13g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com