Acrylic resin and preparation method and application thereof

A technology of acrylic resin and acrylic monomer, which is applied in the field of photoresist, can solve the problems that cannot meet the requirements of 65nm photolithography process, and achieve the effect of reducing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The embodiment of the present invention provides a method for preparing an acrylic resin. Described acrylic resin preparation method comprises the steps:

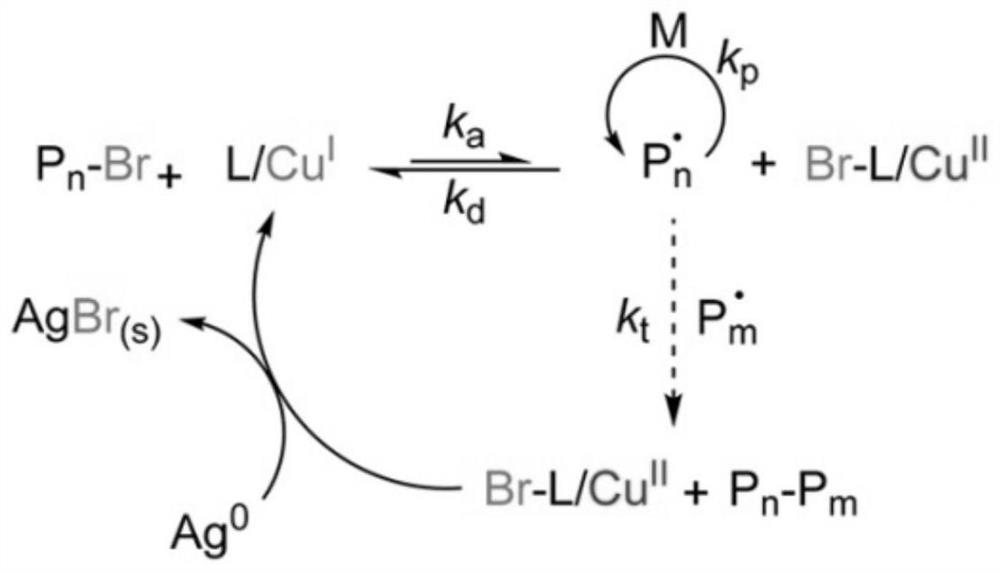

[0017] The acrylic acid monomer, cuprous bromide, ligand, initiator and reducing agent are mixed in a reaction solvent, and then polymerized; wherein, the reducing agent is simple silver, and the reducing agent is sufficient.

[0018] In this way, in the preparation method of the acrylic resin, on the basis of the traditional ATRP polymerization process, a mild reducing agent of zero-valent silver is added, so that the monovalent copper ion in the polymerization reaction process is kept at a constant low concentration, so that the active polymerization reaction process can be control, so that the number average molecular weight distribution of the polymerization reaction process is kept in a very low range, that is, the acrylic resin produced by the polymerization method of the acrylic resin has a lower number averag...

Embodiment 1

[0040] The present embodiment provides a kind of preparation method of acrylic resin, comprises the following steps:

[0041] (1) Clean the inside of the 5L reactor with pure water, dry it with nitrogen gas for later use, fill the reactor with nitrogen gas for later use, mix butyl acrylate, adamantyl acrylate, butyrolactone acrylate, ethyl acetate, bromine Cuprous chloride, methyl-triamine, and silver elemental substances are respectively in proportions of 50g: 50g: 50g: 200g: 1.2g: 2g: 0.05g, weighed, put into the reaction kettle, stir and mix uniformly and set aside for use;

[0042] (2) Heat up the reactor to 69°C, put 0.1g of ethyl 2-bromoisobutyrate into the reactor, and the reaction starts; control the temperature of the reactor, and continue the reaction for 7 hours;

[0043] (3) Cool the reactor temperature to room temperature, drop into diethyl ether 1000g in the kettle, produce a large amount of precipitation, export liquid, retain the solid in the reactor; inject so...

Embodiment 2

[0046] The present embodiment provides a kind of preparation method of acrylic resin, comprises the following steps:

[0047] (1) Clean the inside of the 5L reactor with pure water, dry it with nitrogen for use; fill the reactor with nitrogen for use, and mix methyl acrylate, methyl adamantyl acrylate, propyl butyrolactone, methanol , cuprous bromide, butyl-triamine, and silver are 120g: 30g: 50g: 200g: 1.4g:

[0048] 4.8g: 0.07g, put into the reaction kettle after weighing, stir and mix evenly and set aside;

[0049] (2) Reactor is heated up to 80 DEG C, in the reactor, drop into the initiator shown in 1g above general formula III, reaction begins; Control reactor temperature, continue reaction 7 hours;

[0050] (3) Cool the temperature of the reactor to room temperature, drop into the diethyl ether 3000g in the kettle, produce a large amount of precipitation, export the liquid, keep the solid in the reactor; inject the solvent, continue to drop into the diethyl ether in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com