Nano emulsified oil displacement agent and preparation method thereof

An oil-displacing agent, nano-technology, applied in the field of nano-emulsion oil-displacing agent and its preparation, can solve the problems such as cumbersome preparation process, achieve the effects of simple synthesis process, enhanced oil recovery, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

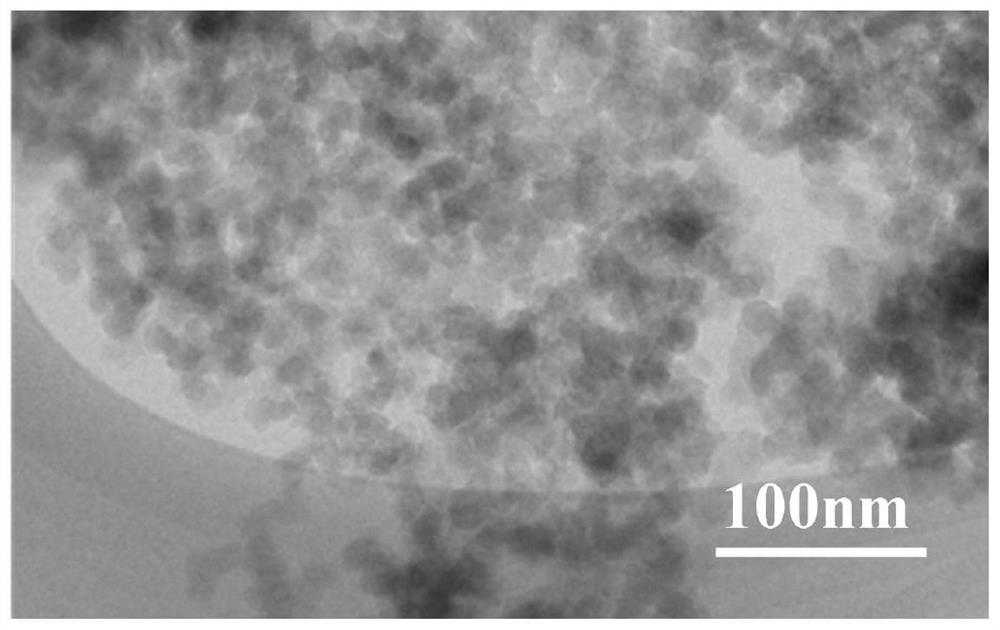

[0036] Embodiment 1: the preparation of nanoemulsion oil displacement agent 1

[0037] Add 30g of absolute ethanol, 4g of ammonia water with a mass concentration of 25%, and 4g of distilled water in sequence in a three-necked bottle equipped with an agitator, seal it, and stir and mix it evenly in a water bath environment at room temperature; Ethyl ester is quickly added in the three-necked bottle; then in the water bath condition at room temperature, the 44g ethanol solution that is dissolved with 0.8g oleic acid, 2.6g cocamide polyoxyethylene ether is added dropwise at a constant speed in the three-necked bottle for 1h through the dropping funnel, Stir quickly during the dropwise addition to ensure that the reaction system is evenly mixed; after the dropwise addition, stir and react in a water bath at room temperature for 24 hours. After the reaction, filter the reaction product with suction, collect the solid product, dry it in vacuum at 50°C and grind it to obtain nanoemulsio...

Embodiment 2

[0038] Embodiment 2: the preparation of nanoemulsion oil displacement agent 2

[0039] Add 50g of absolute ethanol, 2.4g of ammonia water with a mass concentration of 25%, and 3g of distilled water in sequence in a three-necked bottle equipped with a stirrer, seal it, stir and mix it evenly in a water bath environment at room temperature; Ethyl ester was quickly added to the three-necked bottle; then, in a water bath at room temperature, 30 g of ethanol solution dissolved with 0.6 g of oleic acid and 1.0 g of fatty acid diethanolamide was added dropwise to the three-necked bottle at a constant speed for 1 hour through the dropping funnel, and the dropping process Stir quickly in medium to ensure that the reaction system is evenly mixed; after the dropwise addition, stir and react in a water bath at room temperature for 24 hours. After the reaction, filter the reaction product with suction, collect the solid product, dry it in vacuum at 50°C and grind it to obtain a nano-emulsio...

Embodiment 3

[0040] Embodiment 3: the preparation of nanoemulsion oil displacement agent 3

[0041] Add 38.2g absolute ethanol, 3.0g mass concentration of 25% ammonia, 2.0g distilled water successively in a three-necked bottle equipped with a stirrer, seal, stir and mix evenly in a water bath environment at room temperature; Ethyl orthosilicate was quickly added to the three-necked flask; then, in a water bath at room temperature, 40 g of ethanol solution dissolved with 0.6 g of oleic acid, 1.2 g of fatty acid diethanolamide, and 1.0 oleamide was poured into the three-necked flask at a constant rate through the dropping funnel. Add dropwise for 1 hour, stir quickly during the dropwise addition to ensure that the reaction system is evenly mixed; after the dropwise addition, stir and react in a water bath at room temperature for 24 hours, after the reaction, filter the reaction product with suction, collect the solid product, and dry it in vacuum at 50°C Grinding to obtain nano-emulsion oil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com