Copper-based MOF hydrogel functionalized antibacterial film as well as preparation method and application thereof

A hydrogel and functionalization technology, applied in medical science, absorbent pads, bandages, etc., can solve the problems of poor barrier to external bacteria, reduce cytotoxicity, and poor hydrogel strength, so as to improve biocompatibility and reduce Painful, reduced antibacterial properties dependent on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

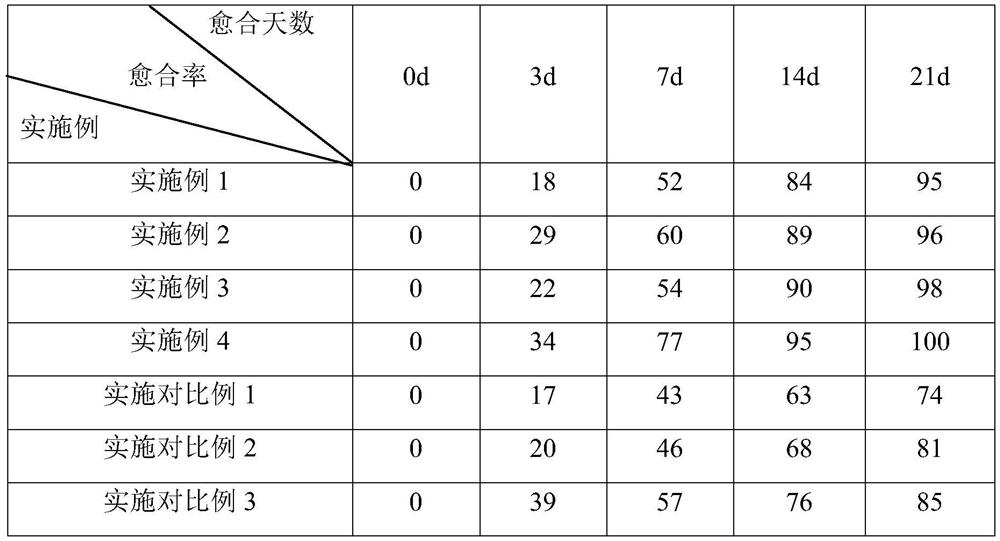

Examples

Embodiment 1

[0040] A preparation method of a copper-based MOF hydrogel functionalized antibacterial film, comprising the steps of:

[0041] (1) Dissolving 2.00g of chitosan in 150mL of acetic acid aqueous solution with a mass percentage concentration of 1%, adjusting the pH value to 3.8 with a 2% NaOH solution with a mass percentage concentration, adding 3.28mL glycidyl methacrylate; The system was reacted in a constant temperature water bath at 60°C for 6 hours, and the product was dialyzed with deionized water for 4 days using a dialysis bag with a molecular weight cut-off of 8000-14000 (Shanghai Yuanye Biotechnology Co., Ltd. MD1477 ordinary dialysis bag) to remove impurities and unreacted Monomer; then freeze-dried to obtain vinyl chitosan derivatives (CS-GMA).

[0042] (2) Dissolve 0.42g (2mmol) 1,3,5-benzenetricarboxylic acid and 0.60g (3mmol) copper acetate monohydrate in 10mL ethanol and deionized water respectively, then mix the two solutions, Stir at 300rpm for about 20min to f...

Embodiment 2

[0046] A preparation method of a copper-based MOF hydrogel functionalized antibacterial film, comprising the steps of:

[0047] (1) 3.0g chitosan is dissolved in 200mL mass percentage concentration and is 1% in the acetic acid aqueous solution, is that the NaOH solution of 4% mass percentage concentration is adjusted pH value to 8, adds 1.38mL methacrylic anhydride; System is at room temperature The product was reacted for 24 hours, and the product was dialyzed with deionized water for 3 days using a dialysis bag with a molecular weight cut-off of 8,000 to 14,000 to remove impurities and unreacted monomers; then freeze-dried to obtain a vinyl chitosan derivative (CS-MA ).

[0048] (2) Dissolve 0.42g (2mmol) 1,3,5-benzenetricarboxylic acid and 0.60g (3mmol) copper acetate monohydrate in 10mL ethanol and deionized water respectively, then mix the two solutions, Stir at 300rpm for about 30min to form a gel-like dark turquoise suspension; separate the particles by centrifuging th...

Embodiment 3

[0052] A preparation method of a copper-based MOF hydrogel functionalized antibacterial film, comprising the steps of:

[0053](1) Dissolve 3g of pigskin gelatin in 30ml of 0.25M carbonate buffer solution (pH=9) at 50°C; under stirring, add 0.36mL of methacrylic anhydride dropwise at a rate of 0.1ml / min In gelatin carbonate buffer solution; the system was reacted in a constant temperature water bath at 60°C for 3 hours, and 5 times the volume of phosphate buffer solution (pH=7.2-7.4) was added to terminate the reaction, and the product was transferred to a medium with a molecular weight cut-off of 8000-14000 In the dialysis bag, use deionized water to dialyze for 5 days to remove impurities and unreacted monomers; then freeze-dry the methacrylated gelatin (Gel-MA) solution.

[0054] (2) Dissolve 0.42g (2mmol) 1,3,5-benzenetricarboxylic acid and 0.60g (3mmol) copper acetate monohydrate in 10mL ethanol and deionized water respectively, then mix the two solutions, Stir at 300rpm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com