Lithium-rich manganese-based precursor and preparation method thereof, lithium-rich manganese-based positive electrode material and preparation method thereof, and lithium ion battery

A technology of lithium-rich manganese-based, cathode material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

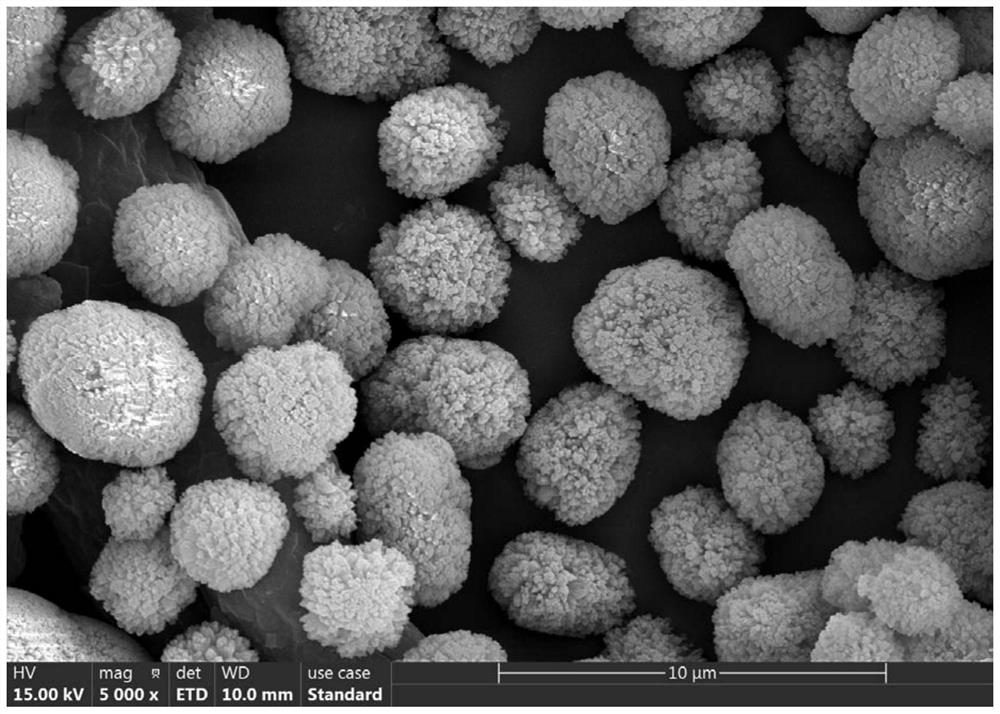

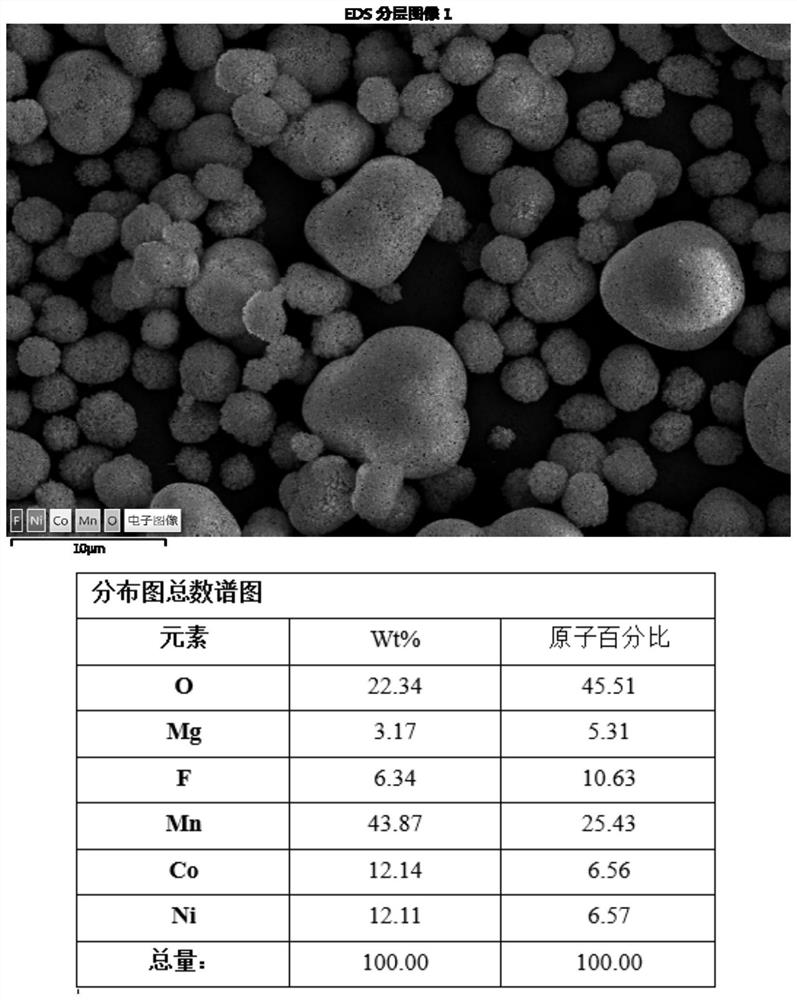

[0045] This embodiment provides a lithium-rich manganese-based positive electrode material whose chemical formula is Li 1.2 mn 0.53 Mg 0.01 Ni 0.13 CO 0.1 3 o 1.98 f 0.02 .

[0046] This embodiment also provides a preparation method for the above-mentioned lithium-rich manganese-based positive electrode material, including the following steps:

[0047] The first step: preparation of lithium-rich manganese-based precursor:

[0048] (1) Configure mixed salt solution: according to the stoichiometric ratio in the molecular formula, accurately weigh nickel sulfate, cobalt sulfate, manganese sulfate and magnesium sulfate, the molar ratio Ni:Co:Mn:Mg=13:13:53:1, and Configure a transition metal salt solution with a total metal concentration of 2mol / L;

[0049] (2) Configure double precipitant solution: configure a sodium carbonate solution with a concentration of 2mol / L, add corresponding proportions of ammonium fluoride and urea of 0.1mol / L;

[0050] (3) Reaction: Use a ...

Embodiment 2

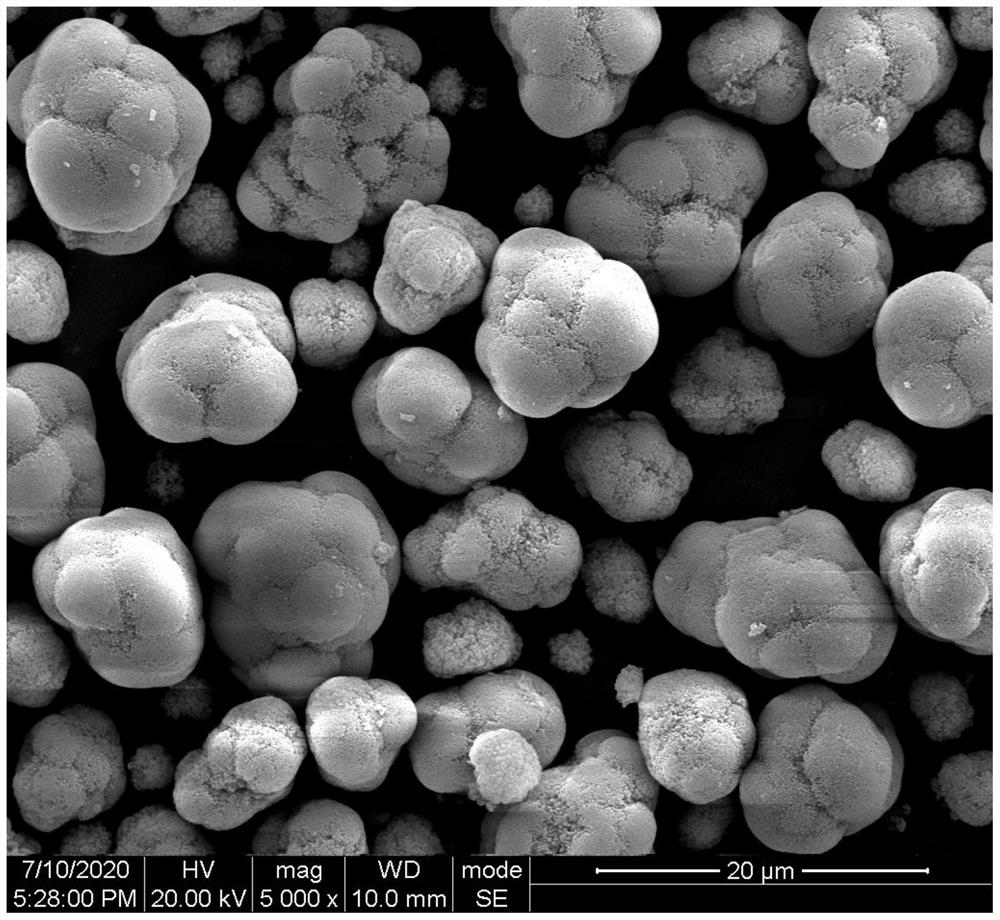

[0054] This embodiment provides a lithium-rich manganese-based positive electrode material whose chemical formula is Li 1.2 mn 0.52 Mg 0.02 Ni 0.13 CO 0.1 3 o 1.96 f 0.04 .

[0055] This embodiment also provides the preparation method of the above-mentioned lithium-rich manganese-based positive electrode material, which differs from the preparation method in Example 1 in that:

[0056] Step (1) configure the mixed salt solution: take nickel sulfate, cobalt sulfate, manganese sulfate and magnesium sulfate according to the stoichiometric ratio in the molecular formula of this embodiment, and the molar ratio Ni:Co:Mn:Mg=13:13:52 : 2, and configure a transition metal salt solution with a total metal concentration of 2mol / L;

[0057] In step (3), the aging time is 24h.

Embodiment 3

[0059] This embodiment provides a lithium-rich manganese-based positive electrode material whose chemical formula is Li 1.2 mn 0.50 Mg 0.04 Ni 0.13 CO 0.1 3 o 1.92 f 0.08 .

[0060] This embodiment also provides the preparation method of the above-mentioned lithium-rich manganese-based positive electrode material, which differs from the preparation method in Example 1 in that:

[0061] Step (1) is configured in the mixed salt solution: accurately weigh nickel sulfate, cobalt sulfate, manganese sulfate and magnesium sulfate according to the stoichiometric ratio in the molecular formula of the present embodiment, and the molar ratio Ni:Co:Mn:Mg=13:13: 50:4, and configure a transition metal salt solution with a total metal concentration of 2mol / L;

[0062] In step (3), the aging time is 36h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com