Macromolecular nano biological filter element material as well as preparation method and application thereof

A polymer and biological filtration technology, applied in the field of nanomaterials, can solve the problems of poor long-term stability of antibacterial performance, short duration of sustained release, uneven dispersion of antibacterial ions, etc., to achieve less scarring, promote wound healing, high The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

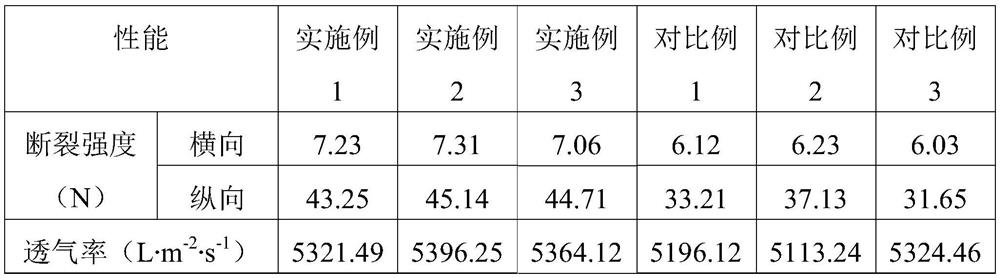

Examples

Embodiment 1

[0046] A kind of macromolecule nano-biological filter element material of the present embodiment, comprises following raw material and is made: Nano-titanium dioxide 1kg, nano-silicon dioxide 4kg, high-melting index polypropylene 50kg, electret masterbatch 3kg, coupling agent 0.008kg, macromolecule 0.03kg of nanoparticles, 0.13kg of toughening agent, 0.012kg of antioxidant and 0.7kg of POE elastic composite material; wherein, the particle diameter of nano-titanium dioxide is 5nm, and the particle diameter of nano-silicon dioxide is 25nm. The melt index of propylene is ≥1700, the coupling agent is coupling agent ST-5, the polymer nanoparticles are polyglycolide, and the antioxidant is tetrakis[β-(3,5-di-tert-butyl -4-Hydroxyphenyl) propionate] pentaerythritol ester.

[0047] The preparation method of the polymer nano-biological filter material of the present embodiment comprises the following steps:

[0048] (1) according to the parts by weight of each raw material, take by we...

Embodiment 2

[0054] A kind of macromolecule nano-biological filter element material of the present embodiment, comprises following raw material to make: Nano-titanium dioxide 2.5kg, nano-silicon dioxide 2.5kg, high melting point polypropylene 75kg, electret masterbatch 2.5kg, coupling agent 0.01kg , polymer nanoparticle 0.02kg, toughening agent 0.15kg, antioxidant 0.01kg and POE elastic composite material 1kg; Wherein, the particle diameter of nano-titanium dioxide is 7.5nm, the particle diameter of nano-silica is 20nm, described high Melt index polypropylene has a melt index ≥ 1700, the coupling agent is coupling agent ST-5, the polymer nanoparticles are polyglycolide, and the antioxidant is tetrakis[β-(3,5-di tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0055] The preparation method of the polymer nano-biological filter material of the present embodiment comprises the following steps:

[0056] (1) according to the parts by weight of each raw material, take by weighin...

Embodiment 3

[0062] A kind of macromolecule nano-biological filter element material of the present embodiment, comprises following raw material and is made: Nano-titanium dioxide 4kg, nano-silicon dioxide 1kg, high-melting index polypropylene 100kg, electret masterbatch 2kg, coupling agent 0.012kg, macromolecule Nanoparticles 0.01kg, toughening agent 0.17kg, antioxidant 0.008kg and POE elastic composite material 1.3kg; Wherein, the particle diameter of nano-titanium dioxide is 10nm, the particle diameter of nano-silicon dioxide is 15nm, and described high-melting finger polymer The melt index of propylene is ≥1700, the coupling agent is coupling agent ST-5, the polymer nanoparticles are polyglycolide, and the antioxidant is tetrakis[β-(3,5-di-tert-butyl -4-Hydroxyphenyl) propionate] pentaerythritol ester.

[0063] The preparation method of the polymer nano-biological filter material of the present embodiment comprises the following steps:

[0064] (1) according to the parts by weight of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com